8

Section 1 - Outdoor Furnace Installation

GENERAL INSTALLATION INFORMATION

Foundation

The outdoor furnace may be installed directly on stable,

level ground without the necessity of a foundation.

If the ground is unstable, one option is to use patio

blocks under the perimeter of the base. Another option

is to pour a concrete foundation.

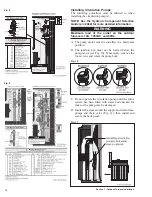

To install the outdoor furnace on a concrete foundation,

refer to Fig. 3 for dimensions and for the location of the

hollowed-out area for each model. A 4" to 6" (10 to 15

cm) thick concrete slab works well; however, a thicker

slab may be used to obtain the desired door opening

height.

Fig. 3

If the area for the concrete slab is unstable and/or

affected by frost heaving, consider installing 2" closed-

cell insulation beneath the front portion of the slab and

under the area of the ground used for walking (see Fig.

3).

NOTE: The installation surface or foundation

must be noncombustible. The hot supply and

return lines must also be protected from possible

exposure to sunlight, fire or physical damage.

Foundations may consist of concrete, crushed

rock or patio blocks.

Potable Water

If the outdoor furnace is to heat potable water associated

with commercial food preparation or for heating milk-

house hot water, it is recommended to install a double-

wall heat exchanger. Also, when filling the system with

water, a backflow preventer must be installed in the line

used for filling.

Antifreeze

Most outdoor furnaces are installed without antifreeze

when an existing heating system is in place and there

is no anticipation of leaving the outdoor furnace

unattended for extended periods of time. If the building

being heated has an alternate heat source, system water

may be kept from freezing by running the circulating

pump(s) and drawing heat from the existing heat

emitter(s).

To prevent freezing if the outdoor furnace is not fired for

extended time periods or if lengthy power outages are

anticipated during cold weather, a nontoxic propylene

glycol boiler-type may be used in the system. Some

types of antifreeze that contain various inhibitors

have been known to create problems like coagulation

and jelling. To prevent potential problems, do not

use propylene glycol that is premixed with unknown

inhibitors. Central Boiler Corrosion Inhibitor Plus (p/n

1650) is compatible with straight propylene glycol. It is

important to use Corrosion Inhibitor Plus with straight

propylene glycol for corrosion protection. If adding

antifreeze to the system, it is imperative that the entire

system contain at least 30% antifreeze concentration

mixed with softened water to prevent bacterial growth

and minimize minerals in the system. Bacterial growth

is likely to occur with low antifreeze concentrations and

can cause corrosion in the furnace water jacket and/or

clogging of heat exchangers. To confirm the antifreeze

solution is adequate, allow the pumps to circulate for at

least 24 hours and then obtain a sample of the system

water. Using an antifreeze tester, the solution must be

protected to 0˚F (-18˚C) or below.

NOTE: Be sure to adhere to all warnings and

precautions on the antifreeze label.

NOTE: Do not use automotive or RV types of

antifreeze.

NOTE: If using antifreeze, use Test Kit (p/n 597)

when testing the treated water in the outdoor

furnace (see Water Quality and Maintenance).

Corrosion Inhibitor Plus™

To aid in protecting the system from corrosion, it is

imperative to add Central Boiler Corrosion Inhibitor

Plus™ (p/n 1650). When initially filling the system (see

Finalizing the Installation), add the Corrosion Inhibitor

Plus™ before adding water to the system. Any time

water is added to the system, Corrosion Inhibitor Plus™

must be added if a tested water sample indicates it is

necessary (see Water Quality and Maintenance).

Summary of Contents for e-Classic 1450 IR

Page 17: ...15 Section 1 Outdoor Furnace Installation...

Page 29: ...27 Section 1 Outdoor Furnace Installation Fig 30 Fig 31...

Page 30: ...28 Section 1 Outdoor Furnace Installation Fig 32 Fig 33...

Page 66: ...64 E CLASSIC 1450 WIRING DIAGRAM Section 6 General Information...

Page 67: ...65 Section 6 General Information E CLASSIC 1450 WIRING DIAGRAM OPTIONAL POWER IGNITION...

Page 69: ...67 NOTES...

Page 70: ...68 NOTES...

Page 71: ...69 NOTES...