26

ENG

"humiFog direct" +0300073EN rel. 1.0 - 31.03.2017

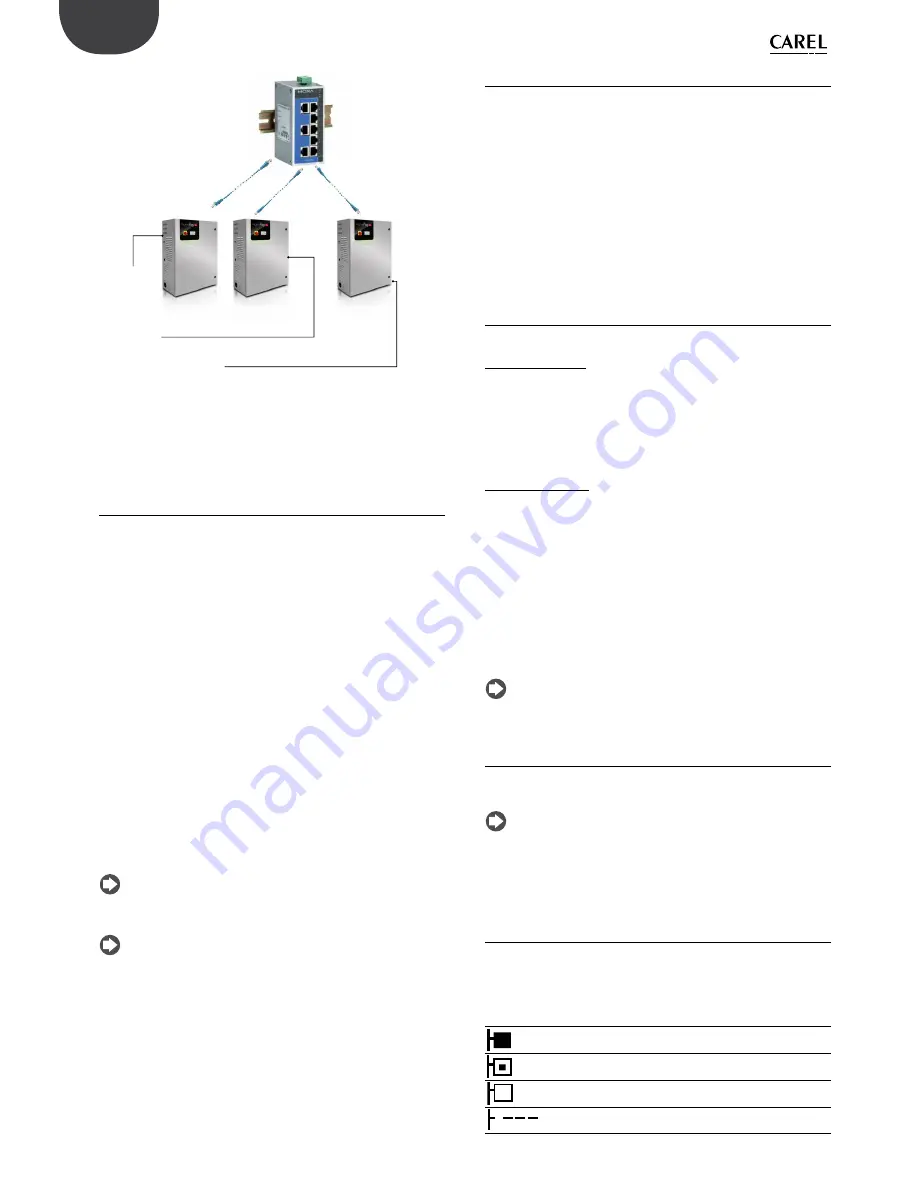

Master

Slave

Slave

IP: 192.168.1.2

IP: 192.168.1.1

IP: 192.168.1.3

Fig. 7.d

Systems set up in this way will be able to cover the humidification

requirement. In this specific case, the Master will always be the unit

with the lowest IP address of those connected to the signal/probes. If

necessary, an additional humidifier (backup) can be installed to cover

request in the event of malfunctions on one of the units in the system.

7.4 Master/Slave system configuration

To configure the Master/Slave system, proceed as follows:

1.

Connect the probes or the external signal to the unit and complete the

configuration (control type, type of signal, maximum production …);

2.

Set the IP addresses of the individual units so that they belong to the same

subnetwork (subnet mask); the screen index for this configuration is Dg04

(D. Settings – g. Supervision). The IP address is set on the display on each

unit, assigning a different address to each unit in the same subnetwork.

If necessary, contact the local network administrator. Remember that the

default address for each unit is 192.168.0.1, and the default subnet mask

is 255.255.255.0. For further details see paragraph 8.1.1 “IP address and

network configuration”

3.

Connect the units making up the Master/Slave system to the local

Ethernet network via a switch. If using just two units, an RJ45 category 5

cable can be used, connected directly to the Ethernet ports on the two

c.pHC controllers.

4.

Configure the Master/Slave system by enabling the units one at a time

(this operation can be performed on the display on any of the units):

4.1 Display screen index Dd01 and then access configuration mode

by pressing “PRG”.

4.2 Enter the IP address for “Unit 1” and confirm by pressing “ENTER”.

4.3 Repeat the operations described above (4.1 and 4.2) for all the

other units in the Master/Slave system.

(The units will join the Master/Slave system (online) immediately

after being added to the network.)

Note:

the Master unit will always (automatically) be the one with

the lowest IP address out of the units connected to the probes or external

signal.

Note:

it may take a few seconds (max 10 s) for the Master to start

sending the production request to the Slave/Slaves. This is also true

when, automatically, the Master unit is changed (for example, in the

event of malfunctions).

7.4.1

Maximum Master/Slave system production

In the same way as for the individual unit configuration, for the Master/

Slave system the maximum capacity can also be set. To set the maximum

capacity, go to menu Dd03. The “Capacity” parameter identifies the

maximum production request for the Master/Slave system, and can

therefore be set by the user.

The “Maximum capacity” parameter (read-only), on the other hand,

indicates the sum of the sizes of each unit added to the system; this

value is therefore the maximum effectively available to the Master/Slave

system. Consequently, “Capacity” will always be ≤ “Maximum capacity”.

In any case, the maximum production can be defined for each individual

unit in the system by limiting production from its maximum according

to the size. In this case, “Maximum capacity” will be updated keeping in

consideration these reductions..

7.4.2

Unit production distribution logic in the

Master/Slave system

The activation logic of the units in the Master/Slave system can be set,

choosing between “Grouped” or “Balanced”, on screen Dd03.

Grouped distribution

•

the units are activated in series, one after the other, according to the

request.

Example:

M/S system comprising two 80 kg/h units, for a maximum total

capacity of 160 kg/h. While the request remains below 50% (80 kg/h)

only one unit will be activated (for example, Unit 1), as soon as the

request exceeds the 50%, the second unit will also be activated (in the

example, Unit 2).

Balanced distribution:

•

the units are activated in parallel at the same time, splitting the total

production request between the number of units in the M/S system.

Example:

M/S system comprising two 80 kg/h units, for a maximum

total capacity of 160 kg/h. If the request is 50%, both Unit 1 and Unit 2

will be activated at 50% of production (40 kg/h + 40 kg/h = 80 kg/h). If

the request is 90% (144 kg/h), both Unit 1 and Unit 2 will be activated

at 90% (72 kg/h + 72 kg/h = 144 kg/h).

For Grouped Distribution only, if the request does not require the use

of all the units, the automatic rotation function can ensure that the

individual units total the same number of operating hours. To enable

and configure the operating hours for unit rotation, set the “auto-rotation

time” parameter on screen Dd04.

Note:

if the “auto-rotation time” parameter is = 0, the auto-rotation

function is disabled.

7.4.3

Disconnect unit from the Master/Slave system

To remove a unit from the Master/Slave system, thus reducing the number

of units available in the system, use the “Disconnect unit” function on

screen Dd06. This can be done on any of the humidifiers in the system.

Note:

once the unit has been disconnected, this will no longer be

visible in the Master/Slave system, as its IP address will be removed from

the list. If a unit is disconnected erroneously, the system can be restored

on screen Dd01 (entering its IP). This must be done from the display on a

unit that is already connected to the system.

7.4.4

Display Master/Slave system

To display a summary of the Master/Slave system, go to screen Dd08.

The menu displays all the units (01, 02, …), the status of each unit and

current production as a percentage. The following table lists the Master/

Slave network unit status indications:

Symbol

Unit status in the Master/Slave system

Indicates the current unit being displayed (PGD or web server)

The unit is: online

The unit is: offline

Unit not configured and not included in the Master/Slave

system

Summary of Contents for humiFog direct

Page 2: ......

Page 4: ...4 ENG humiFog direct 0300073EN rel 1 0 31 03 2017...

Page 6: ...6 ENG humiFog direct 0300073EN rel 1 0 31 03 2017...

Page 43: ......