30

G Vbat DI1 S4V S3

S2

S1

G0 GND DI2 S4I Vr1 Vr2 OC

NT

C -5

0T1

05 °C

S3

Temperature

NTC*WF*

Digital input

DI1

GND

GND

DI1

ratio

OUT

Vr1

Ratiometric

pressure SPKT*R*

GND

P

S1

MOLEX

®

Mini-Fit 538-39-01-2140

G Vbat DI1 S4V S3

S2

S1

G0 GND DI2 S4I Vr1 Vr2 OC

NT

C 0T1

50 °C

S2

NTC*HT*

GND

GND

PT1

000

S2

TSQ*

NT

C -5

0T1

05 °C

S1

NTC*WF*

GND

DI2

DI1

GND

GND

4…2

0 mA

S4I

0…1

0 V

S4V

+

GND

10

mA ma

x

10

Vdc ma

x

OC

+

GND

GND

DI2

or

Vr2 S2

S3

or

ratio

OUT

SPKT*R*

GND

P

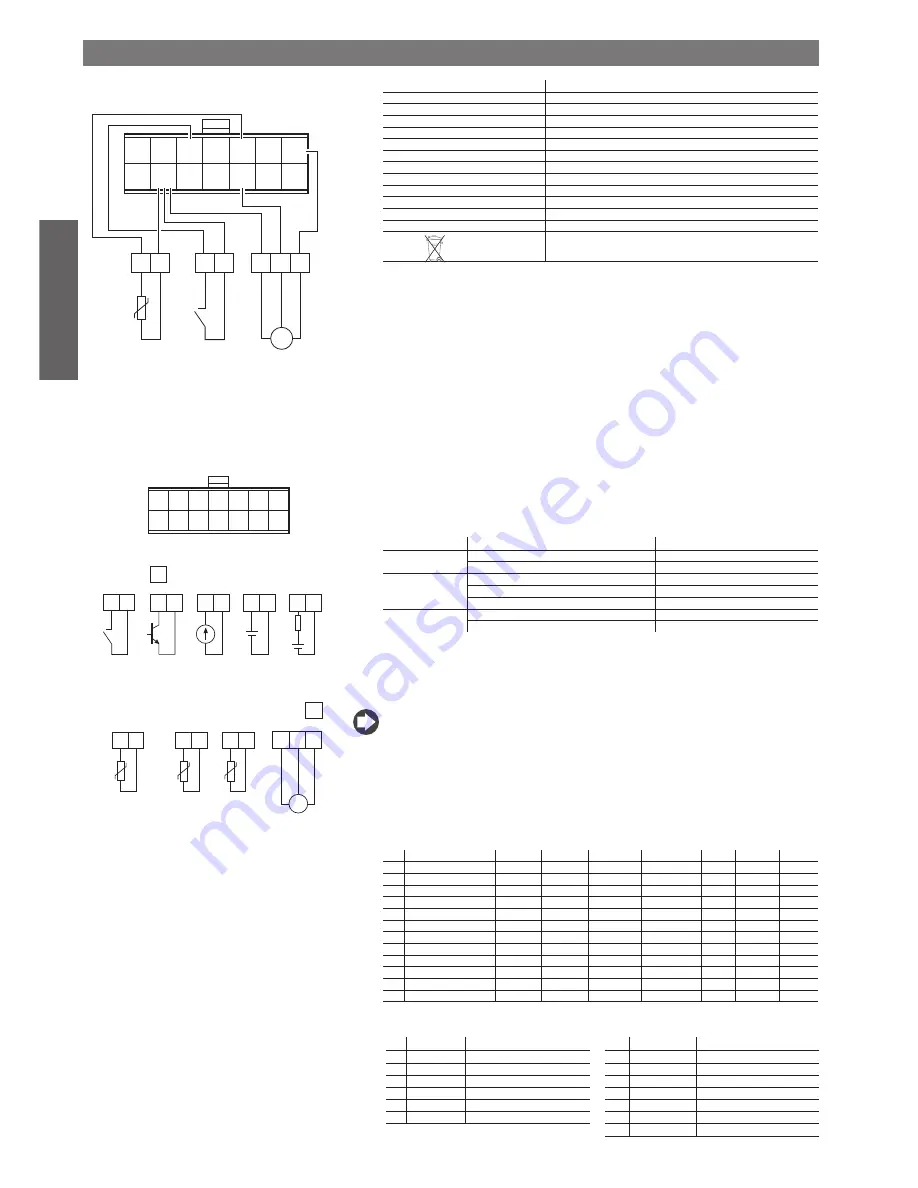

Fig. 4.1

Fig. 4.2

ENGL

ISH

EVD

4

+030220227 - rel. 2.1 - 12.06.2008

4. TECHNICAL AND CONSTRUCTIONAL SPECIFICATIONS

Installation and storage specifi cations

Operating conditions

-10T60°C, < 90% RH non-condensing

Storage conditions

-20T70°C, < 90% RH non-condensing

Index of protection

IP20

Wire cross-section

0.5 to 2.5 mm

2

Dimensions

70 x 110 x 60

PTI of insulating materials

250 V

Protection against electric shock

to be integrated into class I and/or II equipment

Degree of environmental pollution

normal

Resistance to heat and fi re

category D

Immunity against voltage surges

category 1

Surface temperature limits

as per the operating conditions

Assembly

on DIN rail

Case width

4 modules

Disposal

the module is made up of metal and plastic parts. These must be

disposed of according to the waste disposal local legislation in force

Motor control

The controller works with two-pole stepper motors (Fig. 1). It works with a theoretical sinusoidal wave-

form, in micro-steps and with speeds from 5 to 1000 steps; the current and the control speed effectively

achievable depend on the resistance and the inductance of the motor windings used. If the driver is

connected to a pCO, it receives all the individual operating parameters for the motor from the pCO

controller, if, on the other hand, it is used in stand-alone mode or with the microchiller controller, only

one parameter needs to be set, taken from Table 5, according to the model of motor used (see Table 5).

The controller can manage motors with maximum positions of up to 32000 steps. For connection use

4-wire shielded cables, AWG18/22, max. length 9.5 m. The shield should be connected to the closest

possible earth point in the panel.

Power supply

Power supply: 20 to 28 Vac or 20 to 30 Vdc 50/60 Hz to be protected by external 0.8 A fuse, type T.

Use a class II safety transformer rated to at least 20 VA. Average current input at 24 Vac: 60 mA with the

motor not operating (control logic only); 240 mA with CAREL motor operating (240 mA peak at 18

Ω

).

Emergency power supply: if the optional EVBAT00200/300 module is installed, power supply is

guaranteed to the controller for the time required to close the valve.

Inputs and outputs

Analogue inputs (*)

input

type

CAREL code

S1-S3:

NTC (-50T105 °C)

NTC*WF*

Raziom. (0,5…4,5 Vdc)

SPKT*R*

S2:

NTC (0T150 °C)

NTC*HT*

Raziom. (0,5…4,5 Vdc)

SPKT*R*

Pt1000

TSQ*

S4:

current at 100

Ω

4…20 mA

voltage at 1 k

Ω

0…10 V

Digital inputs ID1 and ID2: controlled by voltage-free contact or transistor, have a no-load voltage of 5 V and

deliver 5 mA short-circuited.

Digital output OC: open-collector transistor; max no-load voltage 10 V, max current 10 mA.

Relay output: normally open contact; 5 A 250 Vac resistive load; 2 A 250 Vac, inductive load (PF= 0.4).

(*) WARNING!

All analogue inputs except for S4 V, the digital I/O and the serial port (not optically-

isolated) refer to the GND earth, (Fig. 3) and consequently the even temporary application of voltages

higher than ±5 V to these connectors may cause irreversible damage to the controller. Input S4 V can

tolerate voltages up to 30 V. As GND is the common earth for all the inputs, this should be replicated

on the terminal block with low-resistance connections for each input used. The GNX earth for the serial

connection is electrically connected to the GND earth. The product complies with Directive 89/336/EEC

(EMC). Contact CAREL if specifi c disturbance occurs in the confi guration used. If the connection to the

motor is made using a shielded cable, the cable shield and the channel marked by the earth symbol on

the 6-pin connector must be earthed as near as possible to the EVD400.

Valve table

n°

Model

Step min Step max

Step close

Step/s speed mA pk mA hold % duty

0

CAREL E2V*

50

480

500

100

450

100

30

1

Sporlan SEI 0.5-20

100

1596

3600

200

200

50

70

2

Sporlan SEI 30

200

3193

3600

200

200

50

70

3

Sporlan SEH 50-250

400

6386

7500

200

200

50

70

4

Alco EX5-EX6

100

750

750

450

400

100

70

5

Alco EX7

250

1600

1600

330

750

250

70

6

Alco EX8 330 step/s

250

2600

2600

330

800

500

70

7

Alco EX8 500 step/s

250

2600

2600

500

800

500

70

8

Danfoss ETS-25/50

200

2625

2700

120

140

75

70

9

Danfoss ETS-100

300

3530

3600

120

140

75

70

10

CAREL E2V*P

50

380

400

100

450

100

30

11

Danfoss ETS-250/400 350

3810

3900

120

140

75

70

Table of refrigerants (consult the electronic expansion valve technical documentation to check

the complete valve-driver system compatibility with the chosen refrigerant)

n° “R” number operating temperature

n°

“R” number

operating temperature

1

R22

-40T60

7

R290

-50T96

2

R134a

-40T60

8

R600

-50T90

3

R404a

-40T60

9

R600a

-50T90

4

R407c

-40T60

10

R717

-60T70

5

R410a

-40T60

11

R744

-50T31

6

R507c

-40T60

12

R728

-201T-145

13

R1270

-60T90

Probe connections (Default)

Other connections

Summary of Contents for EVD4

Page 1: ...EVD4 Driver for electronic expansion valve User manual...

Page 2: ......

Page 3: ...User manual...

Page 6: ...6...

Page 44: ...44...

Page 47: ......