23

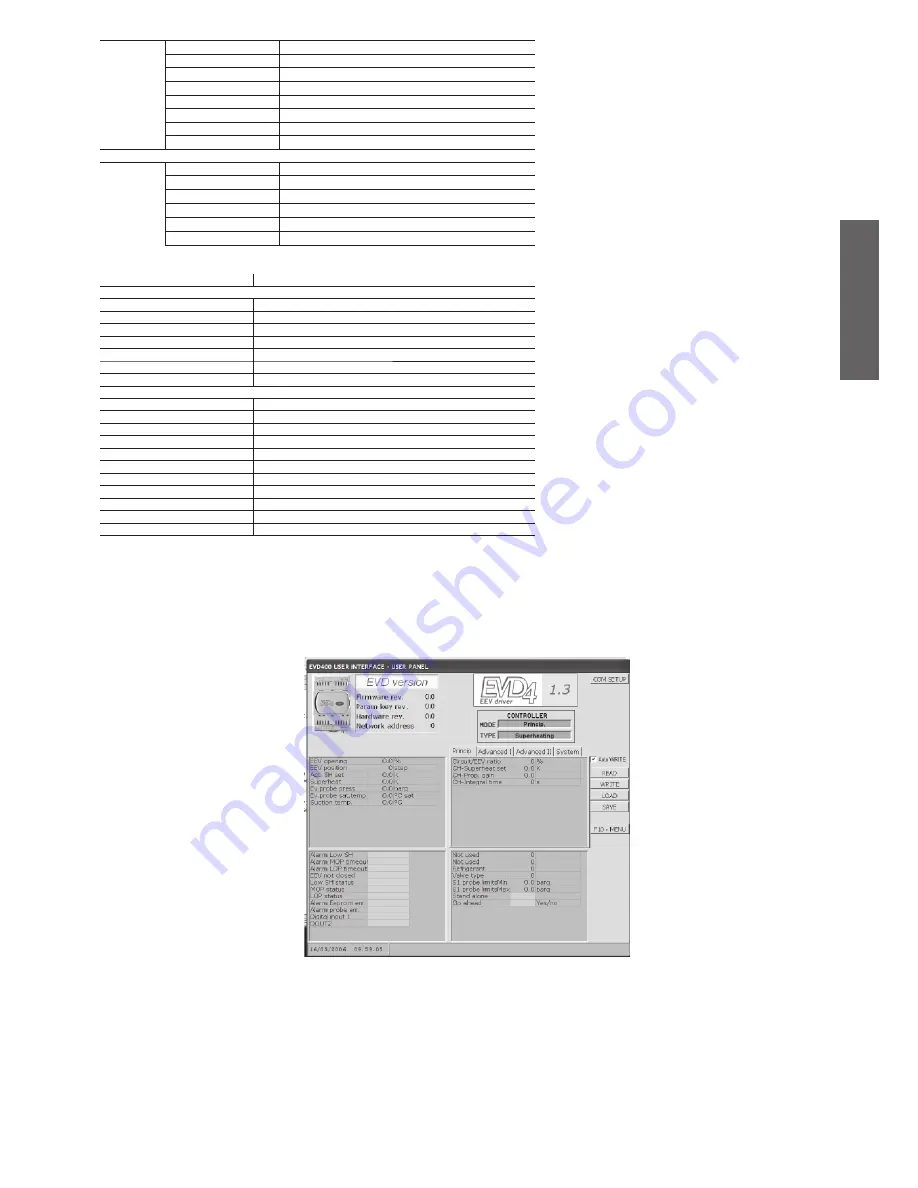

Fig. 3.21

ENGL

ISH

EVD

4

+030220227 - rel. 2.1 - 12.06.2008

System

Minimum steps

minimum control steps

—

Maximum steps

maximum control steps

—

Closing steps

steps completed in total closing

—

Standby steps

number of valve standby steps

—

Steprate

motor speed

—

Phase current

peak current per phase

—

Still current

current with the motor off

—

Duty cycle

motor duty cycle

—

Global parameters (Fig. 3.21)

Refrigerant

number indicating the type of refrigerant used

Valve type

number that defi nes the type of electronic valve used

S1 probe limitsMin barg ‘zero’ scale for pressure sensor on input S1

S1 probe limitsMax barg end scale for pressure sensor on input S1

Stand alone

enable StandAlone

Go ahead

enable restart following error

READ

Parameter name

Description

System measurements (Fig. 3.21)

EEV opening

valve opening as a %

EEV position

calculated electronic expansion valve opening position

Act. SH set

current superheat set point

Superheat

superheat value measured

Ev. probe press.

evaporation pressure value measured by sensor

Ev. probe sat. temp

saturated gas temperature value calculated in the evaporator

Suction temp.

compressor suction temperature value measured by sensor

Digital variables (Fig. 3.21)

Alarm Low SH

active in low superheat conditions

Alarm MOP timeout

active in conditions with excessive evaporation pressure

Alarm LOP timeout

active in conditions with insuffi cient evaporation pressure

EEV not closed

active due to failed valve closing

Low SH status

active when in low superheat control status

MOP status

active when in maximum evaporation pressure control status

LOP status

active when in minimum evaporation pressure control status

Alarm Eeprom err.

active following an EEPROM memory error

Alarm probe err.

active following an error on the signal from the probe

Digital input 1

status of digital input 1

DOUT2

output relay control signal

3.5.3 EVD4_UI user interface

The EVD4_UI user interface is based on the CAREL supervisor protocol and is designed for the easy

and intuitive reading or confi guration of the control parameters. The program can be started in different

confi gurations so as to display the set of parameters that is suitable for the type of installation the EVD4

is used in; to do this, make the connection using the name of the required confi guration.

The interface confi guration for the ‘positioner’ function is shown in Fig. 3.21 and is activated by making

the “EVD4_UI stand alone” connection, as described in APPENDIX I “INSTALLING AND USING THE

EVD4_UI PROGRAM”.

3.5.4 Start-up

After having connected the EVD4, as described in 3.5.1, connect the service serial port to a PC via the

special converter and confi gure the parameters and the address using according to the application and/

or systems used. The controller is already enabled; to switch off the EVD4, disable the Stand-alone

variable or modify the status of digital input D1 (Fig. 2.1) and run the supervisor program (i.e. PlantVisor)

to monitor the system.

Summary of Contents for EVD4

Page 1: ...EVD4 Driver for electronic expansion valve User manual...

Page 2: ......

Page 3: ...User manual...

Page 6: ...6...

Page 44: ...44...

Page 47: ......