CHAPTER 6 FIXING SYSTEM

COPYRIGHT © 1999 CANON INC. CANON PC800s/900s REV.0 AUG. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

6-6

Figure 6-106

Figure 6-105

4.

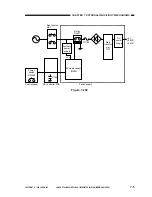

Correcting the Variation in the Resistance of the Fixing Heater

The characteristics of the flat heater used as the fixing heater vary from heater to heater because

the production method. A discrepancy in resistance, if left alone, will not enable correct control of

the fixing heater.

The machine makes correction in relation to the selected level of resistance (from three set-

tings), and corrects it basd on the readings obtained by the microprocessor.

Caution:

The level of resistance of the fixing heater is selected by an appropriate combination of the

jumper wires connected to the connector of the fixing thermistor (TH1) and the delivery

sensor (PS3).

The best level is selected at the factory when the fixing assembly is assembled. Do not change

the combination of jumper wires.

HEAT_PWM

Power supplied

to the heater

3.

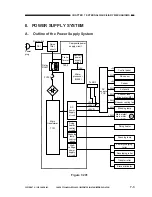

Controlling the Temperature Supplied to the Fixing Heater

The temperature of the fixing heater is controlled by controlling the power supplied to the

fixing heater, and the power to the fixing heater is controlled using a phase control method.

The microprocessor on the DC controller PCB controls the timing at which the fixing heater

duty signal (HEAT_PWM) is generated so that power suited to the target temperature of the fixing

heater may be supplied (phase control).

Summary of Contents for PC920

Page 12: ......

Page 34: ......

Page 36: ......

Page 48: ......

Page 50: ......

Page 92: ......

Page 94: ......

Page 122: ......

Page 124: ......

Page 162: ......

Page 164: ......

Page 180: ......

Page 206: ......

Page 240: ......

Page 242: ......

Page 256: ......

Page 263: ......

Page 265: ......

Page 355: ......

Page 383: ......