Chapter 15

15-1

15.1 Error Code Details

15.1.1 Error Code Details

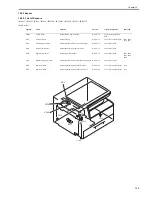

0013-1429

iR1020J / iR1024J / iR1020 / iR1024 / iR1024A / iR1024N / iR1024F / iR1024i / iR1024iF

T-15-1

Display

Code

Detail Code

Main Cause/Symptom

Countermeasure

E000

0000

Startup error

The temperature detected by the main or sub thermistor does

not rise to the specified value during startup control.

- Check the fixing film connector.

- Replace the fixing film unit.

- Replace the DC controller PCB.

E001

0000

Abnormally high temperature (detected by main thermistor)

The main thermistor detected an abnormally high temperature

(235 deg C) during temperature control.

- Check the connector of the fixing film unit.

- Replace the fixing film unit.

- Replace the DC controller PCB.

0001

Abnormally high temperature (detected by sub thermistor)

The sub thermistor detected an abnormally high temperature

(300 deg C) during temperature control.

- Check the connector of the fixing film unit.

- Replace the fixing film unit.

- Replace the DC controller PCB.

E002

0000

Low temperature during temperature control.

The target temperature is not reached during temperature

control.

- Check the connector of the fixing film unit.

- Replace the fixing film unit.

- Replace the DC controller PCB.

E003

0000

Abnormally low temperature (detected by main thermistor)

After the temperature detected by the main thermistor has

reached the specified value, it does not reach the specified

value during initial rotation.

- Check the connector of the fixing film unit.

- Replace the fixing film unit.

- Replace the DC controller PCB.

0001

Abnormally low temperature (detected by sub thermistor)

After the temperature detected by the sub thermistor has

reached the specified value, it does not reach the specified

value during initial rotation.

- Check the connector of the fixing film unit.

- Replace the fixing film unit.

- Replace the DC controller PCB.

E010

0000

Main motor failure

The main motor is faulty.

- Check the connector of the main motor.

- Replace the main motor.

- Replace the DC controller PCB.

E019

0001

Waste toner full detection

The waste toner full state was detected.

Replace the drum unit

0002

Waster toner full detection sensor is faulty.

The waste toner full state was detected continuously for five or

more seconds while the main motor was turning.

- Check the connector of the waster toner full sensor.

- Replace the waste toner full sensor.

- Replace the DC controller PCB.

E100

0000

BD detection PCB failure

The BD detection PCB is faulty.

- Check the connector of the BD detection PCB.

- Replace the laser scanner unit.

- Replace the DC controller PCB.

E196

0001

Flash ROM write/read error

- Replace the image processor PCB.

The write/read of Flash ROM in the image processor PCB is

faulty.

0002

PCL ROM write/read error

- Replace the PCL PCB.

- Replace the image processor PCB.

The write/read of PCL ROM in the image processor PCB is

faulty.

E197

0000

Printer engine communication error

Erroneous communication between the DC controller PCB and

image processor PCB was detected.

- Check the connectors of the DC controller PCB and image

processor PCB.

- Replace the DC controller PCB for normal connection.

- Replace the image processor PCB.

E716

0000

Erroneous communication with optional cassette

Disconnection of the optional cassette was detected after

power-on, detection of normal connection to the optional

cassette, and start of communication.

- Check the connectors of the optional cassette PCB and DC

controller PCB.

- Replace the optional cassette PCB for normal connection.

- Replace the DC controller PCB.

Summary of Contents for iR1020 Series

Page 1: ...Sep 1 2008 Service Manual iR1020 1021 1024 1025 Series ...

Page 2: ......

Page 6: ......

Page 17: ...Chapter 1 Introduction ...

Page 18: ......

Page 20: ......

Page 49: ...Chapter 1 1 29 ...

Page 50: ......

Page 51: ...Chapter 2 Installation ...

Page 52: ......

Page 54: ......

Page 61: ...Chapter 2 2 7 ...

Page 62: ......

Page 63: ...Chapter 3 Basic Operation ...

Page 64: ......

Page 66: ......

Page 73: ...Chapter 3 3 7 ...

Page 74: ......

Page 75: ...Chapter 4 Original Exposure System ...

Page 76: ......

Page 78: ......

Page 87: ...Chapter 5 Laser Exposure ...

Page 88: ......

Page 90: ......

Page 94: ......

Page 95: ...Chapter 6 Image Formation ...

Page 96: ......

Page 98: ......

Page 103: ...Chapter 7 Pickup Feeding System ...

Page 104: ......

Page 106: ......

Page 120: ......

Page 121: ...Chapter 8 Fixing System ...

Page 122: ......

Page 124: ......

Page 135: ...Chapter 9 External and Controls ...

Page 136: ......

Page 138: ......

Page 151: ...Chapter 10 Original Feeding System ...

Page 152: ......

Page 154: ......

Page 156: ...Chapter 10 10 2 M2001 ADF motor Symbol Name ...

Page 170: ......

Page 171: ...Chapter 11 e maintenance imageWARE Remote ...

Page 172: ......

Page 174: ......

Page 184: ......

Page 185: ...Chapter 12 Maintenance and Inspection ...

Page 186: ......

Page 188: ......

Page 190: ......

Page 191: ...Chapter 13 Standards and Adjustments ...

Page 192: ......

Page 194: ......

Page 201: ...Chapter 14 Correcting Faulty Images ...

Page 202: ......

Page 204: ......

Page 214: ......

Page 215: ...Chapter 15 Self Diagnosis ...

Page 216: ......

Page 218: ......

Page 224: ......

Page 225: ...Chapter 16 Service Mode ...

Page 226: ......

Page 230: ......

Page 232: ...Chapter 16 16 2 Makes various status checks such as contact sensor sensor and print status ...

Page 278: ......

Page 279: ...Chapter 17 Upgrading ...

Page 280: ......

Page 282: ......

Page 297: ...Chapter 18 Service Tools ...

Page 298: ......

Page 299: ...Contents Contents 18 1 Service Tools 18 1 18 1 1 Special Tools 18 1 ...

Page 300: ......

Page 302: ......

Page 303: ...Sep 1 2008 ...

Page 304: ......