Chapter 18

18-17

F-18-32

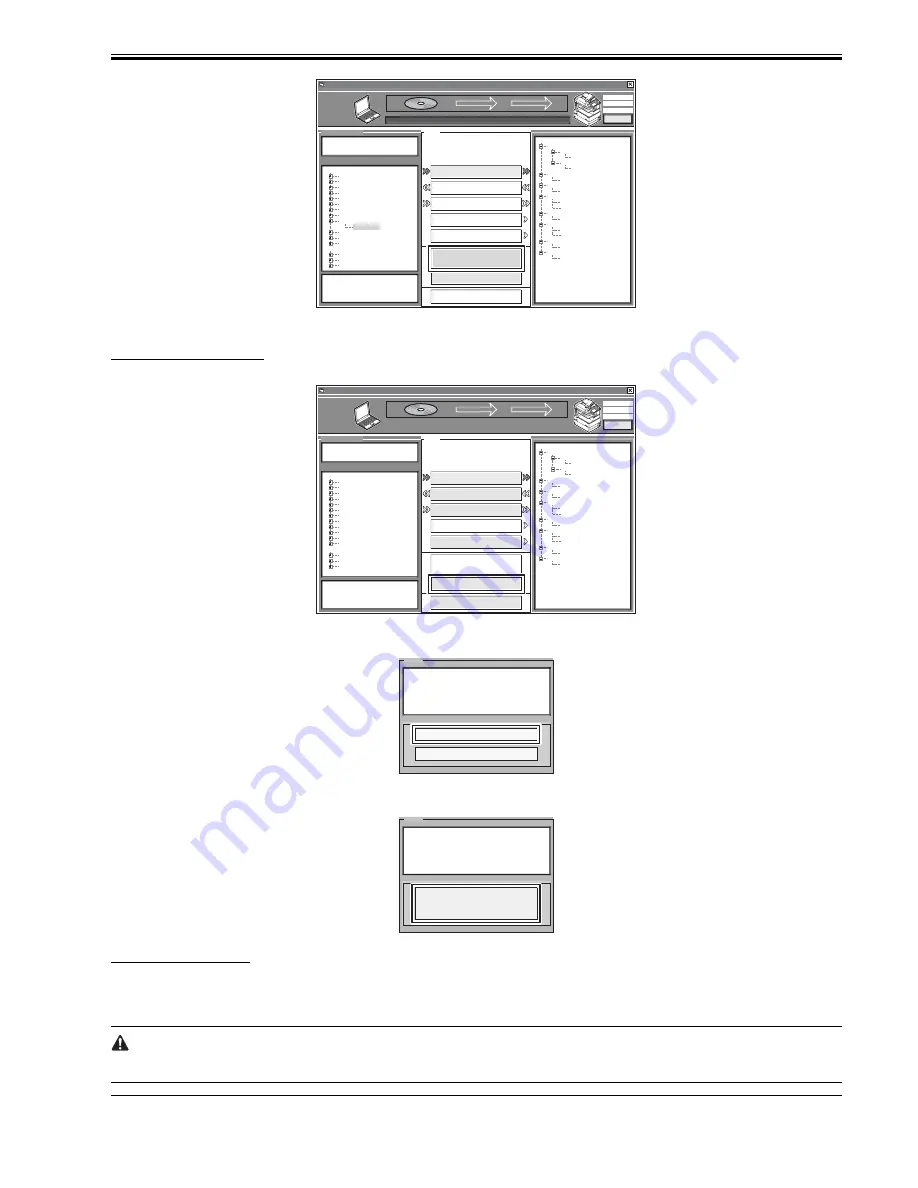

5) Start up the machine. The subsequent procedure differs depending on the download mode.

If the machine is in normal mode,

5-1) Click [Shutdown].

F-18-33

5-2) Click [Start Shutdown] so that the machine starts the shut-down sequence.

F-18-34

5-3) Click [OK], and turn off and then back on the machine's main power switch.

F-18-35

If the machine is in safe mode,

5-1) Turn off and then back on the machine's main power switch.

6) When the machine starts up, it will write the system software to its HDD and flash ROM while showing the progress of writing on the control panel screen. When

done, it will indicate a message asking you to turn off and then back on the power. In response, turn off and then back on the main power.

Turning Off the Power

Do not turn off the machine's power while downloading or writing is under way; otherwise, the machine may fail to start up. If such is the case, execute HDD

formatting, and download the system software once again.

MEMO:

SelectableFirmware

SelectableFir mware

Control

172.16.1.100

iRC3380

NORMAL

SYSTEM

Firmware Version

Active

USenXXXXn

Hold

USenXXXXi

RCON

XXxxXXXX

DCON

XXxxXXXX

MEAPCONT

XXxxXXXX

G3FAX

XXxxXXXX

BOOTROM

XXxxXXXXC

RUI

XXjaXXXX

XXenXXXX

LANGUAGE

XXjaXXXX

XXenXXXX

D ow n l o a d i n g c o m p l e t e

ServiceSupportTool DLM10 (Ver.3.22E)

C l e a r

C l i c k t h e b u t t o n o f t h e t a s k t o b e

exe c u t e d .

Download Firmware

Upload Data

Download Data

Restore Backup System

Format HDD

Return to Main Menu

Shutdown

O K

BOOT

iRC3380

BROWSER

DCON

HDFormat

iRCXXXX

KEY

SDICT

G3FAX

HELP

LANGUAGE

MEAPCONT

RUI

TTS

WebDAV

SYSTEM

TSTMP

USenvXXXX

SelectableFirmware

SelectableFir mware

Control

172.16.1.100

iRC3380

NORMAL

SYSTEM

Firmware Version

Active

USenXXXXn

Hold

USenXXXXi

RCON

XXxxXXXX

DCON

XXxxXXXX

MEAPCONT

XXxxXXXX

G3FAX

XXxxXXXX

BOOTROM

XXxxXXXXC

RUI

XXjaXXXX

XXenXXXX

LANGUAGE

XXjaXXXX

XXenXXXX

ServiceSupportTool DLM10 (Ver.3.22E)

C l e a r

C l i c k t h e b u t t o n o f t h e t a s k t o b e

exe c u t e d .

Download Firmware

Upload Data

Download Data

Restore Backup System

Format HDD

Shutdown

S e l e c t t h e f i r m wa r e t o b e

d ow n l o a d e d . t h e n c l i ck t h e [ S t a r t ]

bu t t o n .

Return to Main Menu

Start

BOOT

iRC3380

BROWSER

DCON

HDFormat

iRCXXXX

KEY

SDICT

G3FAX

HELP

LANGUAGE

MEAPCONT

RUI

TTS

WebDAV

SYSTEM

TSTMP

Message

Start Shutdown

Cancel

Have you finished downloading and want to

star t shutdown sequence for restar ting

machine ?

Message

Follow the instructions shown on the machine

for shutdown process.

Click [OK] button to return to Main Menu.

O K

Summary of Contents for iR C2880 series

Page 1: ...Aug 29 2006 Service Manual iR C3380 2880 Series ...

Page 2: ......

Page 6: ......

Page 23: ...Chapter 1 Introduction ...

Page 24: ......

Page 26: ......

Page 52: ......

Page 53: ...Chapter 2 Installation ...

Page 54: ......

Page 127: ...Chapter 3 Basic Operation ...

Page 128: ......

Page 130: ......

Page 136: ......

Page 137: ...Chapter 4 Main Controller ...

Page 138: ......

Page 160: ......

Page 161: ...Chapter 5 Original Exposure System ...

Page 162: ......

Page 188: ...Chapter 5 5 24 F 5 68 4 Remove the original sensor 2 hook 1 F 5 69 ...

Page 189: ...Chapter 6 Laser Exposure ...

Page 190: ......

Page 192: ......

Page 206: ......

Page 207: ...Chapter 7 Image Formation ...

Page 208: ......

Page 256: ......

Page 257: ...Chapter 8 Pickup Feeding System ...

Page 258: ......

Page 262: ......

Page 303: ...Chapter 9 Fixing System ...

Page 304: ......

Page 306: ......

Page 321: ...Chapter 10 Externals and Controls ...

Page 322: ......

Page 326: ......

Page 336: ...Chapter 10 10 10 F 10 10 2 Remove the check mark from SNMP Status Enabled ...

Page 337: ...Chapter 10 10 11 F 10 11 ...

Page 359: ...Chapter 11 MEAP ...

Page 360: ......

Page 362: ......

Page 401: ...Chapter 12 RDS ...

Page 402: ......

Page 404: ......

Page 411: ...Chapter 13 Maintenance and Inspection ...

Page 412: ......

Page 414: ......

Page 416: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4 ...

Page 421: ...Chapter 14 Standards and Adjustments ...

Page 422: ......

Page 424: ......

Page 431: ...Chapter 15 Correcting Faulty Images ...

Page 432: ......

Page 434: ......

Page 459: ...Chapter 16 Self Diagnosis ...

Page 460: ......

Page 462: ......

Page 481: ...Chapter 17 Service Mode ...

Page 482: ......

Page 484: ......

Page 571: ...Chapter 18 Upgrading ...

Page 572: ......

Page 574: ......

Page 603: ...Chapter 19 Service Tools ...

Page 604: ......

Page 606: ......

Page 609: ...Aug 29 2006 ...

Page 610: ......