VIII-81

I-21 Back

Stain

Phenomenon

Back side of the print paper is stained as shown in

print sample (21) of Fig.8-2

.

Main Causes

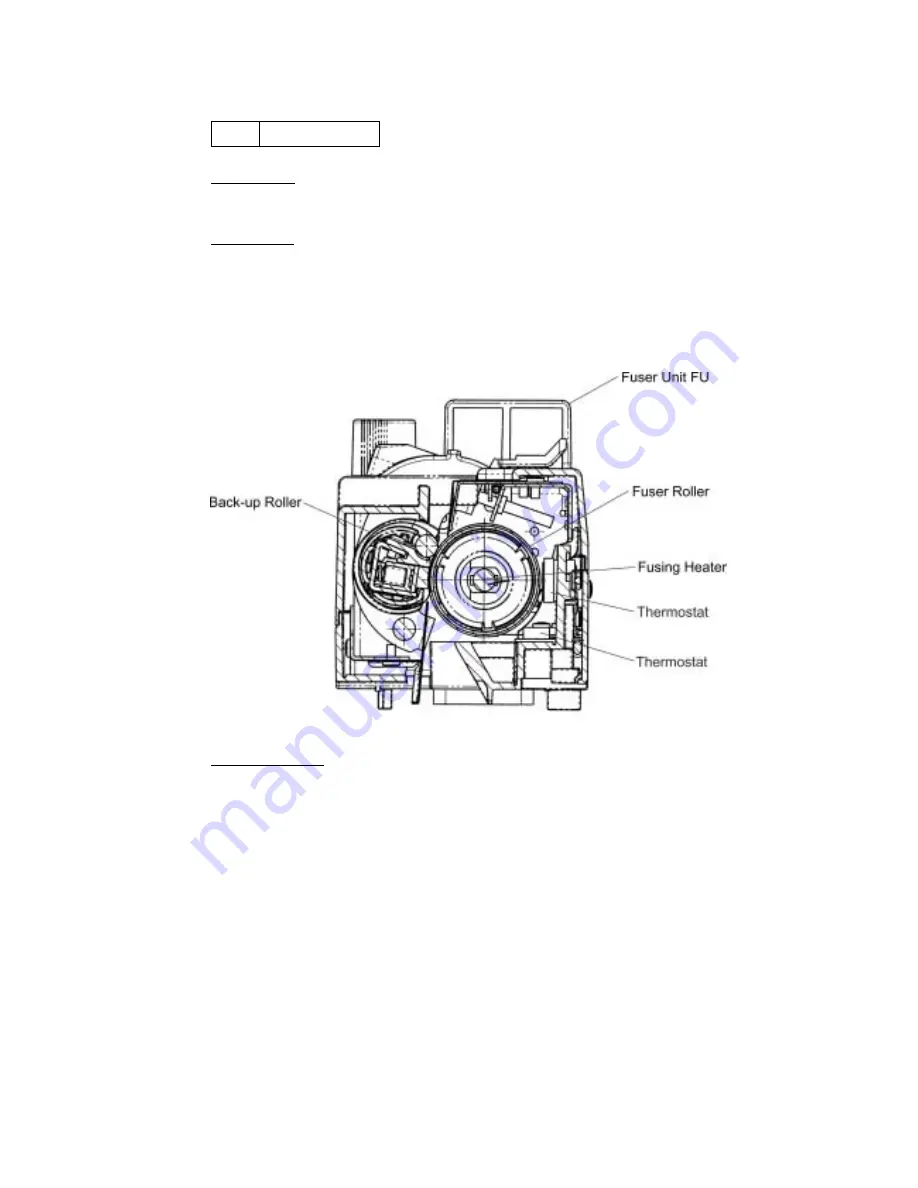

1) Fuser Unit:

1-1) The fuser roller and the back-up roller is stained.

(Print immediately after the inner jam occurred.)

1-2) Fusing off-set error occurred. (Fusing temperature is not correct.)

1-3) The fuser roller and the back-up roller are deteriorated.

2) The transfer roller is stained.

Countermeasures

1) Clean off the stain of the fuser roller by carrying out the blank printing for couple of

pages.

2) Replace the fuser unit FU with a new fuser unit FU.

3) Replace the transfer roller ASSY PU with a new transfer roller ASSY PU.

Summary of Contents for HL-2700CN Series

Page 16: ...viii 3 Rating Label 6 0A 11 0A For Europe For US ...

Page 18: ...CHAPTER I PRODUCT OUTLINE ...

Page 27: ...CHAPTER II SPECIFICATIONS ...

Page 39: ...III 1 CHAPTER III INSTALLATION ...

Page 53: ...CHAPTER IV STRUCTURE OF SYSTEM COMPONENTS ...

Page 84: ...IV 31 Layout of Clutches and Solenoids 1 2 3 4 5 6 7 8 9 10 Fig 4 30 ...

Page 90: ...IV 37 ...

Page 93: ...IV 40 c Interface Circuit Printer side Table 4 1 Interface Circuit ...

Page 102: ...IV 49 Main PCB circuit Diagram 1 7 IV 49 CODE B512168CIR 1 7 LJ9515001 NAME ...

Page 103: ...IV 50 Main PCB circuit Diagram 2 7 IV 50 CODE B512168CIR 2 7 LJ9515001 NAME ...

Page 104: ...IV 51 Main PCB circuit Diagram 3 7 IV 51 CODE B512168CIR 3 7 LJ9515001 NAME ...

Page 105: ...IV 52 Main PCB circuit Diagram 4 7 IV 52 CODE B512168CIR 4 7 LJ9515001 NAME ...

Page 106: ...IV 53 Main PCB circuit Diagram 5 7 IV 53 CODE B512168CIR 5 7 LJ9515001 NAME ...

Page 107: ...IV 54 Main PCB circuit Diagram 6 7 IV 54 CODE B512168CIR 6 7 LJ9515001 NAME ...

Page 108: ...IV 55 Main PCB circuit Diagram 7 7 IV 55 CODE B512168CIR 7 7 LJ9515001 NAME ...

Page 110: ...IV 57 Layout of Connector Pin Assignment Power Supply Unit Fig 4 40 ...

Page 118: ...IV 65 1 MCTL P W B I1CN IOD P W B DCN1 2 MCTL P W B I2CN IOD P W B DCN3 ...

Page 124: ...IV 71 30 Duplex Connector 31 Lower Feeder Connector 32 DCN2 IOD 33 DCN8 IOD LaserFan ...

Page 125: ...CHAPTER V CONTROL PANEL OPERATION ...

Page 171: ...CHAPTER VI PERIODIC MAINTENANCE ...

Page 197: ...CHAPTER VII DISASSEMBLY ...

Page 200: ...VII 3 Table 7 1 Table of Applicable Screws ...

Page 257: ...CHAPTER VIII TROUBLESHOOTING ...

Page 316: ...VIII 59 5 IMAGE FAILURE 1 2 3 4 5 6 7 8 9 10 11 12 13 14 ...

Page 317: ...VIII 60 15 a 15 b 16 17 18 19 20 21 22 23 24 25 Fig 8 2 ...

Page 346: ...A 4 6 Transfer Unit X X X X X X 7 1 2 3 Location DATE MONTH SERIAL NO YEAR ...