BAS-6150

102

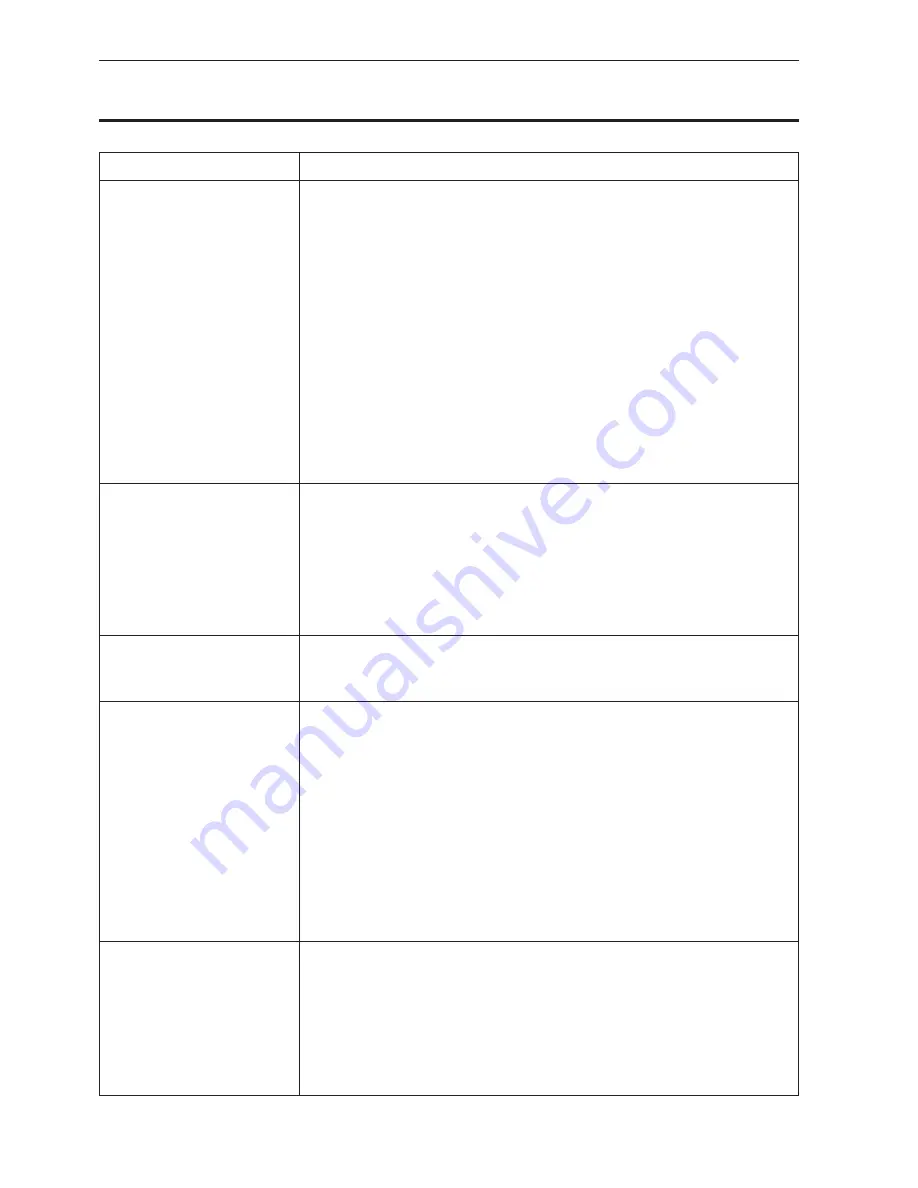

Chapter 10 Troubleshooting

• Is the needle bend ? Is the needle point crushed ?

→

Replace the needle with new one.

• Is the needle correctly attached ?

→

Attach the needle correctly.

• Is the threading correctly performed ?

→

Refer to "How to thread the upper thread".

• Is the tension of upper thread too strong ?

→

Adjust the upper thread to correct tension.

• Is the clearance between the rotary hook and bobbin case opener correctly

adjusted ?

→

Refer to "Timing adjustment of needle and rotary hook".

• Is the timing of needle and rotary hook correctly adjusted ?

→

Refer to "Timing adjustment of needle and rotary hook".

• Is the threading correctly arranged ?

→

Refer to "How to thread the lower thread".

• Is the tension of lower thread correctly adjusted ?

→

Adjust the lower thread to correct tension.

• Is oil or waste thread stuck to the bobbin case ?

→

Get rid of waste thread or wipe put oil.

• Is the needle bend ? Is the needle point crushed ?

→

Replace the needle with new one.

• Is the needle bend ? Is the needle point crushed ?

→

Replace the needle with new one.

• Is the needle correctly attached ?

→

Refer to "How to attach the needle".

• Is the threading correctly arranged ?

→

Refer to "How to thread the upper thread".

• Is the timing of needle and rotary hook correctly adjusted ?

→

Refer to "Timing adjustment of needle and rotary hook".

• Is cut pieces of cloth clogged around the rotary hook ?

→

Clean around the rotary hook.

• Is the resilience and operational scope of thread take up spring proper ?

→

Refer to "Adjusting the thread tension spring".

• Is the tension of upper thread too weak ?

→

Adjust the upper thread to correct tension.

• Is the tension of lower thread too weak ?

→

Adjust the lower thread to correct tension.

Upper thread breakage

Lower thread breakage

Uneven stitch

Stitch skip

Weak tension of threads

Trouble

Reference table in trouble

Check and corrective action

Summary of Contents for BAS-6150

Page 2: ......

Page 11: ...Chapter 1 Machine Preparation ...

Page 29: ...Chapter 2 Sewing flow ...

Page 41: ...Chapter 3 Settings ...

Page 55: ...Chapter 4 Oiling ...

Page 59: ...Chapter 5 Adjustment For raising the head refer to 3 How to raisethehead in Chapter4 Oiling ...

Page 70: ...Chapter 5 Adjustment BAS 6150 68 ...

Page 71: ...Chapter 6 Knife replacement ...

Page 77: ...Chapter 7 Environment setting ...

Page 85: ...Chapter 7 Environment setting BAS 6150 83 Standard stacker 4 steps 0 1 3 4 2 1530S ...

Page 95: ...Chapter 8 Dipswitch ...

Page 98: ...Chapter 8 Dipswitch BAS 6150 96 ...

Page 99: ...Chapter 9 Error code List ...

Page 103: ...Chapter 10 Troubleshooting ...