REF 905-030

36

Instructions for use, ERGO 300 - BOWA- IFU-12930- ERG0300-S0-EN-20210701

Cleaning

Machine cleaning

1. Instruments and attachments are placed in the sieve

basket after pre-cleaning.

2. Machine cleaning is only successful if the pre-cleaning

described above has been complied with!

3. The cleaning is carried out with the Vario TD program

in the cleaning and disinfection device (WD). The use

of fully demineralized water is recommended for the

cleaning process.

4. After completing the cleaning program (including

thermal disinfection), check the instruments and

attachments, including seals and O-rings, for visible

contamination in grooves and spaces. Repeat the clean-

ing if necessary.

Automatic cleaning process (Vario-TD program)

1. Pre-clean for 4 minutes with cold water < 40°C.

2. Empty

3. Clean for 5 minutes at 55°C with 0.5 % alkaline,

or at 40°C with 0.5 % enzymatic cleaner.

4. Empty

5. Neutralize for 3 minutes with cold water < 40°C.

6. Empty

7. Rinse with cold water < 40°C for 2 minutes.

8. Empty

Disinfection

Machine disinfection

The washer/disinfector has a thermal disinfection program

that follows cleaning. The mechanical, thermal disinfection

must be carried out taking into account the national

requirements with regard to the A0 value (see DIN EN

ISO 15883-1). We recommend an A0 value of 3000 for the

electronic motor and the attachments. Disinfection must

be carried out with fully demineralized water.

Warning

Insufficient rinsing or staying in the disinfectant or cleaning

agent for too long can corrode the instruments. Please

refer to the instruction leaflet for the respective cleaning

agent and disinfectant for dwell times.

Drying

Machine drying

The drying of the instruments and the attachments takes

place through the drying cycle of the washer-disinfector.

If necessary, manual drying can also be achieved using

a lint-free cloth. Pay particular attention to the grooves

and spaces between the instruments. Each WD has to

provide a corresponding drying process on the part of the

manufacturer (see ISO 15883-1). Please observe the relevant

information and instructions for use from the manufacturer

of the washer-disinfector.

Manual drying

Set up the instruments vertically, separated from the at-

tachments, in order to encourage the outflow of liquid. Let

the instruments dry for at least 30 minutes.

Control and care

of the electronic

motor

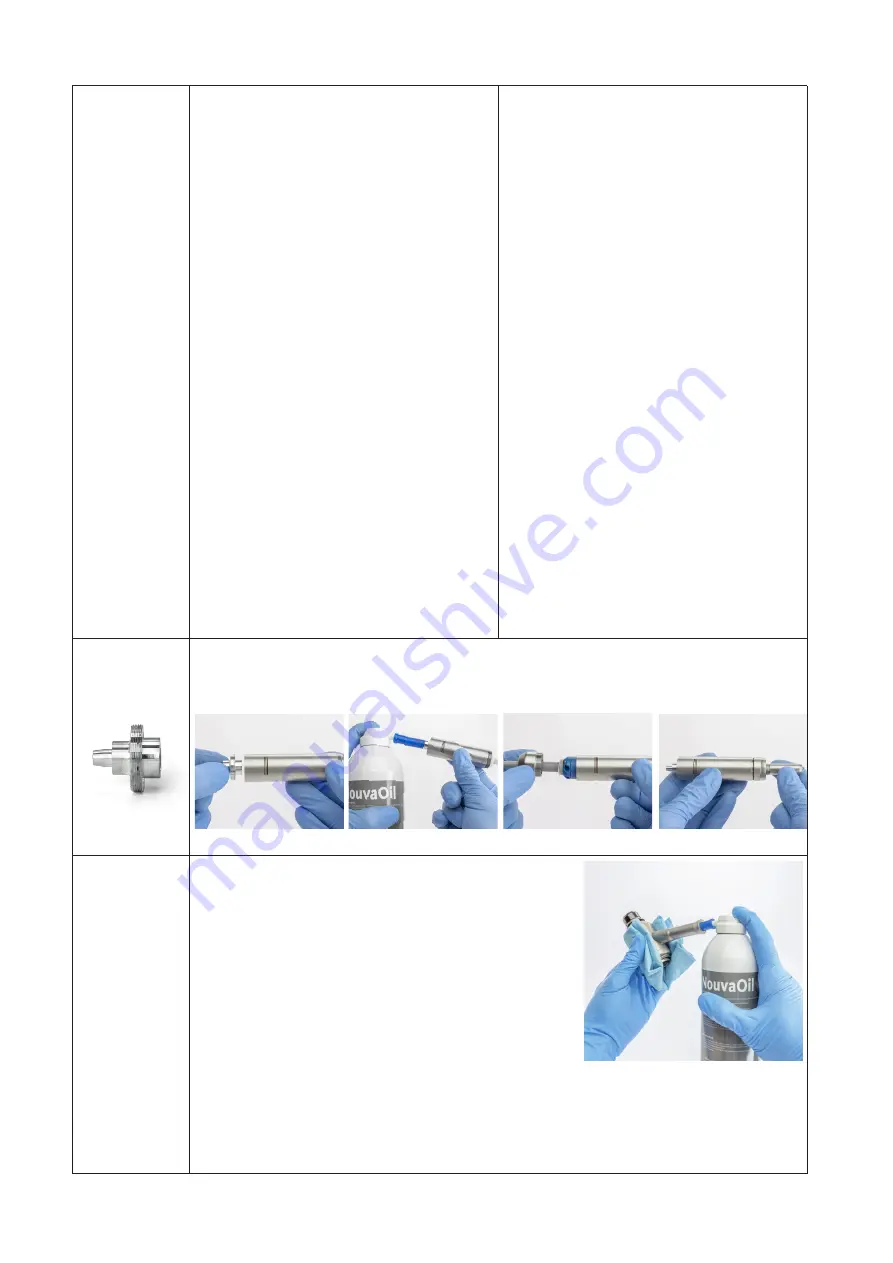

1. Carry out a visual inspection for damage, corrosion and wear, both outside and inside the instruments.

2. To maintain (lubricate) the electronic motor, these are sprayed through with NouvaOil spray from the clutch side for

approx. 3 seconds. To do this, the spray attachment REF: 905-030 is screwed on instead of the plug motor cap.

3. Then wipe the electronic motor with a damp cloth.

Control and care of

the transmission

unit

1. Carry out a visual inspection for damage, corrosion and wear, both

outside and inside the gear unit.

2. To maintain (lubricate) the gear unit, spray it with NouvaOil spray from

the clutch side for approx. 3 seconds. To do this, the blue spray attach-

ment supplied with the NouvaOil spray is inserted into the coupling of

the gear unit and a puff of spray is released for approx. 3 seconds. Oil

introduced under pressure can escape from the pressure equalization

opening of the gear unit.

3. Then wipe the transmission unit with a damp cloth.