Summary of Contents for 301 DFS

Page 1: ...1 2 1 2 1 2 Operator Manual BINDOMATIC 301 DFS Document Finishing System...

Page 2: ...2 Part No 8K100...

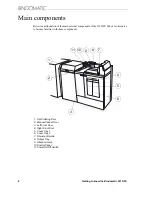

Page 24: ...18 Getting to know the Bindomatic 301 DFS Notes...

Page 42: ...36 Making the documents...

Page 52: ...46 Customising your Bindomatic 301 DFS Notes...

Page 59: ...Problem solving 53 F2 F3 F4 F5 F6 F7 F8 F8 F1 F9...

Page 78: ......

Page 79: ...73 Appendix A Safety information...

Page 83: ...Safety information 77...

Page 84: ...78 Safety information...