General inspection and repair

Note

Before inspection and repair

Move the machine to level surface.

Apply the parking brake, and then lower the

operating machine.

Stop the engine, and then remove the key.

Clean the machine.

Be sure to clean parts such as the piping,

hoses, and hydraulic fittings.

Remember that cleaning is always

necessary upon inspection and repair of

hydraulic systems.

Warning

Be sure to depressurize the hydraulic system

before inspecting or repairing it.

When piping and hoses are removed, put a

cap or plug in its place to prevent

contamination of the hydraulic systems.

Attach labels or other identifications to the

removed piping and hoses so that they can

be correctly refitted.

When removing piping and hoses, pay

special attention to the connection part.

If necessary, mark the piping and hoses to

ensure correct fitting.

After inspection and repair

Caution

After the installation, check if there is no

hydraulic oil leakage in each part.

See the list in "Tightening torques" (Page

3-5) .

Note that the Baroness product warranty may

not apply to defects caused by incorrect or

overtorque tightening etc.

Check the amount of oil in the hydraulic

tank. Add as necessary.

In the event that failure or contamination is

found in the hydraulic circuit, replace the

hydraulic oil and filter.

When fitting hydraulic fittings, apply

hydraulic oil onto the O-ring.

Fit hoses and hydraulic fittings only after

removing the cap and plug.

1.

2.

3.

4.

5.

6.

7.

1.

2.

3.

When fitting hoses and hydraulic fittings,

follow the proper procedure for tightening.

After repair, check to see whether the

hydraulic system functions normally and

whether there are any broken parts.

When the hydraulic system has been

repaired or replaced, operate the machine

slowly, idling the engine, to allow the air to

go out of the circuit.

Make sure that there is no oil leakage.

In the event of leakage, stop the engine, set

the oil stopper, and check the amount of oil

in the hydraulic tank.

Add oil if necessary.

4.

5.

6.

7.

FS900

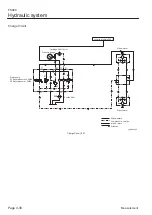

Hydraulic system

Page 4-40

General inspection and repair

Summary of Contents for FS900

Page 1: ...Riding Sweeper Service Manual Serial No FS900 10001 Ver 1 0...

Page 4: ...FS900 Contents...

Page 10: ...FS900 Safety Page 1 6 Safety Signs and Instruction Signs...

Page 11: ...Waste Disposal Page 2 2 About the Waste disposal Page 2 2 Disposal FS900 Disposal Page 2 1...

Page 28: ...FS900 Maintenance standards and maintenance Page 3 16 Greasing...

Page 74: ...FS900 Hydraulic system Page 4 46 Inspection and repair of each section...

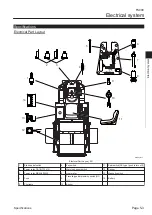

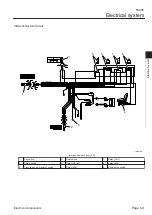

Page 98: ...FS900 Electrical system Page 5 24 General inspection and repair...

Page 118: ...FS900 Main body Page 6 20 Inspection and repair of each section...