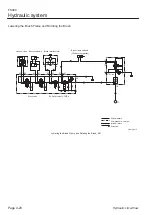

Towing

Important

Going over the limit of towing may lead to the

failure of hydraulic equipment.

Also, if the machine is towed at high speed,

the wheel may cease its motion.

Stop towing in case of wheel lock.

Resume towing at low speed after the

pressure has been stabilized.

In the event of loss of mobility due to engine

trouble or the like of, movement is possible

through towing or hand driving.

Take the shortest route when towing or hand

driving the machine.

Transport the machine on a trailer if you have

to transport it a long way.

For the towing method, see the Owner's

manual.

Neutral

If the machine goes forward or in reverse

without pressing on the forward/reverse

pedals, the neutral is not working. Adjust

accordingly.

Refer to the Owner's manual for adjustment of

the neutral.

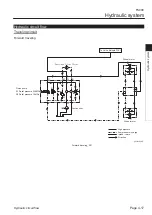

Depressurization

Be sure to depressurize the hydraulic system

before inspecting or repairing it.

When performing depressurization, move the

machine to level surface.

Apply the parking brake, and then lower the

operating machine.

Then, stop the engine and remove the key.

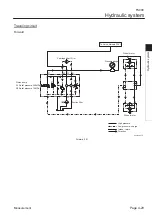

To depressurize the hydraulic circuit, set the

traveling pedal and all the drives of the

operating machine to the neutral position.

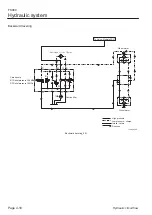

Hydraulic circuit failure

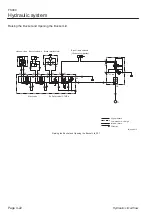

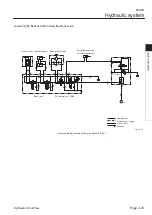

The hydraulic traveling circuit of this equipment

is made up of a closed circuit.

In the event of failure of the hydraulic

equipment of the hydraulic circuit, debris and

contaminant from the faulty hydraulic

equipment will circulate to every part of the

circuit.

Since this contaminant causes damage to

other hydraulic equipment, such debris and

contaminant must be removed to prevent

further failure of other hydraulic equipment.

In the event that failure of hydraulic equipment

is found in the hydraulic circuit, remove

hydraulic hoses and piping of the whole

hydraulic circuit and clean them well with

kerosene.

Drain all the hydraulic oil from hydraulic tank

and hydraulic equipment other than the

hydraulic hoses and piping and clean them

well.

We recommend to replace the hydraulic oil,

hydraulic oil filter and defective hydraulic

equipment with new ones.

FS900

Hydraulic system

Page 4-16

General instructions

Summary of Contents for FS900

Page 1: ...Riding Sweeper Service Manual Serial No FS900 10001 Ver 1 0...

Page 4: ...FS900 Contents...

Page 10: ...FS900 Safety Page 1 6 Safety Signs and Instruction Signs...

Page 11: ...Waste Disposal Page 2 2 About the Waste disposal Page 2 2 Disposal FS900 Disposal Page 2 1...

Page 28: ...FS900 Maintenance standards and maintenance Page 3 16 Greasing...

Page 74: ...FS900 Hydraulic system Page 4 46 Inspection and repair of each section...

Page 98: ...FS900 Electrical system Page 5 24 General inspection and repair...

Page 118: ...FS900 Main body Page 6 20 Inspection and repair of each section...