Maintenance

About Maintenance

This chapter provides descriptions of the main

inspection and maintenance procedures for the

FS900 work machine.

For information on daily checks, maintenance

and handling of the machine, please refer to

the separate FS900 Owner's Operating Manual

and Parts Catalog.

For information on attaching and removing

optional parts and attachments, refer to the

handling instructions for the corresponding

attachment.

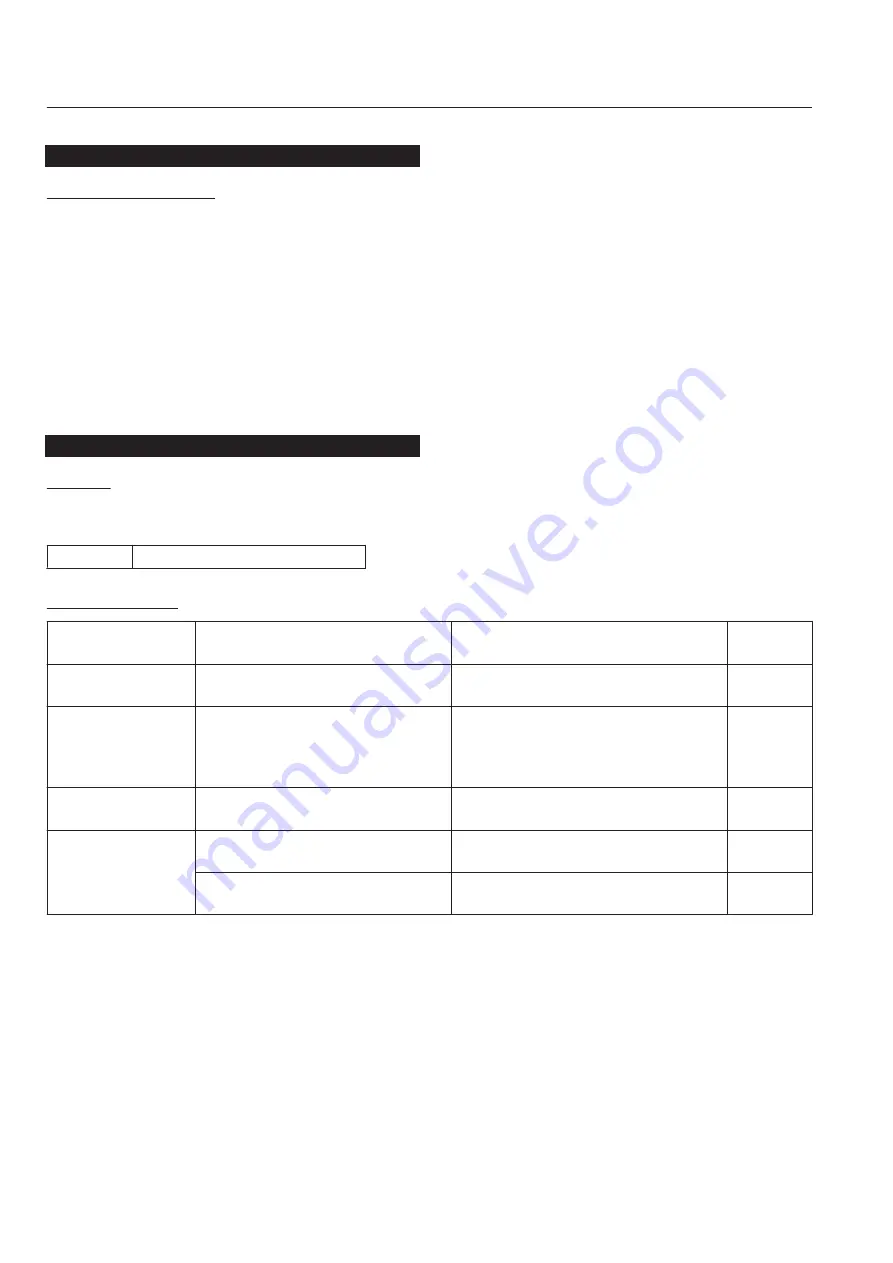

Specifications

Grease

Use the following type of grease on the

operating machine and mower units.

Grease

Excelite EP No. 2 (urea base)

Adjusted Value

Adjustment of

brushes

Gap between brush and frame

5 mm

0.197 in

Adjustment of rotary

plates

Gap between rotary plate and frame 5 mm

0.197 in

Adjustment of belt

tension

Brush belt

The V-belt should slack by

approximately 10 mm when you press

the middle of the belt with your finger at

98 N (10 kgf).

Adjustment of bucket

Gap between operating machine and

bucket contact surface

10 mm

0.393 in

Adjustment of bucket

lid

Gap between bucket and lower area

of lid

1 mm

0.039 in

Screwing distance of rod end and

piston rod

20 mm

0.787 in

FS900

Operating Machine and Mower Units

Page 7-2

Maintenance

Summary of Contents for FS900

Page 1: ...Riding Sweeper Service Manual Serial No FS900 10001 Ver 1 0...

Page 4: ...FS900 Contents...

Page 10: ...FS900 Safety Page 1 6 Safety Signs and Instruction Signs...

Page 11: ...Waste Disposal Page 2 2 About the Waste disposal Page 2 2 Disposal FS900 Disposal Page 2 1...

Page 28: ...FS900 Maintenance standards and maintenance Page 3 16 Greasing...

Page 74: ...FS900 Hydraulic system Page 4 46 Inspection and repair of each section...

Page 98: ...FS900 Electrical system Page 5 24 General inspection and repair...

Page 118: ...FS900 Main body Page 6 20 Inspection and repair of each section...