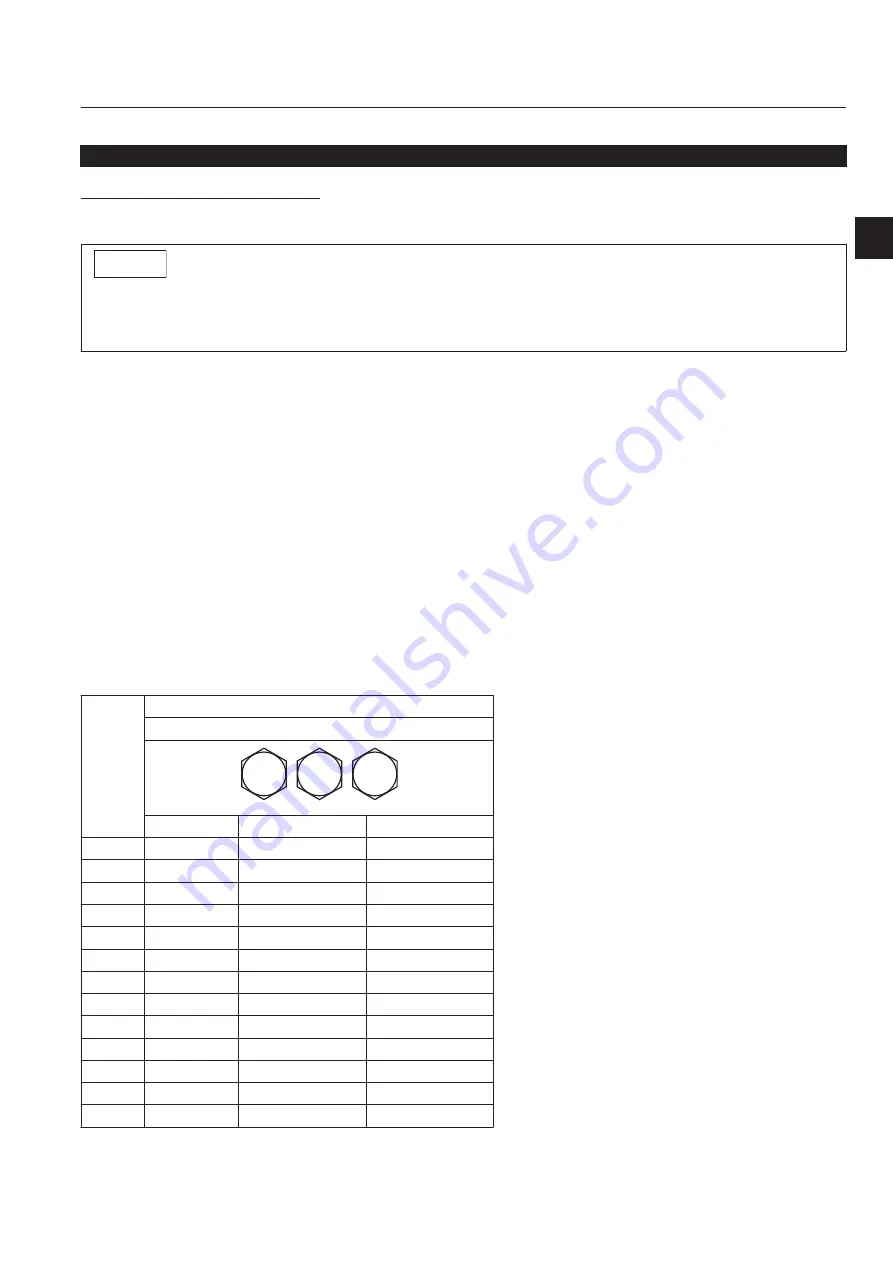

Tightening torques

Standard tightening torques

Bolts and Nuts

Important

A number of bolts are used in each part of this machine.

Be sure to re-tighten the bolts and nuts, because they may be loosened at the earlier stage of the

use.

As to the bolts and nuts without any special instruction, tighten them in appropriate tightening torque

with proper tool.

Too much tightening may cause the looseness or damage of the screw.

The strength of tightening is determined by types of screws, strength, the friction of thread face or

base face and others.

The table below is for the galvanized or parkerized bolts.

In case that the strength of internal thread is weak, it is not applied.

Do not use rusty or sand attached "screw."

Otherwise, it may cause insufficient tightening even if you apply the specified tightening torque.

The friction of the screw face becomes higher and the tightening torque is canceled out by the

friction, therefore sufficient tightening cannot be applied.

If "screw" is wet by water or oil, do not tighten it with normal tightening torque.

If the screw is wet, the torque coefficient will get smaller and it may result in too much tightening.

Too much tightening may cause looseness by the screw stretched or result in damage.

Do not use a bolt experienced too much burden.

Using the impact wrench requires the skill.

Do exercise as much as possible for steady tightening.

Nominal

diameter

General bolt

Strength classification 4.8

M

4 T

4.8

tib3yb-001

N-m

kgf-cm

lb-in

M5

3 - 5

30.59 - 50.99

26.55 - 44.26

M6

7 - 9

71.38 - 91.77

61.96 - 79.66

M8

14 - 19

142.76 - 193.74

123.91 - 168.17

M10

29 - 38

295.71 - 387.49

256.68 - 336.34

M12

52 - 67

530.24 - 683.20

460.25 - 593.02

M14

70 - 94

713.79 - 958.52

619.57 - 831.99

M16

88 - 112

897.34 - 1142.06

778.89 - 991.31

M18

116 - 144

1,182.85 - 1,468.37

1,026.72 - 1,274.54

M20

147 - 183

1,498.96 - 1,866.05

1,301.10 - 1,619.73

M22

295

3,008.12

2,611.05

M24

370

3,772.89

3,274.87

M27

550

5,608.35

4,868.05

M30

740

7,545.78

6,549.74

Maintenance standards and maintenance

FS900

Maintenance standards and maintenance

Page 3-5

Tightening torques

Summary of Contents for FS900

Page 1: ...Riding Sweeper Service Manual Serial No FS900 10001 Ver 1 0...

Page 4: ...FS900 Contents...

Page 10: ...FS900 Safety Page 1 6 Safety Signs and Instruction Signs...

Page 11: ...Waste Disposal Page 2 2 About the Waste disposal Page 2 2 Disposal FS900 Disposal Page 2 1...

Page 28: ...FS900 Maintenance standards and maintenance Page 3 16 Greasing...

Page 74: ...FS900 Hydraulic system Page 4 46 Inspection and repair of each section...

Page 98: ...FS900 Electrical system Page 5 24 General inspection and repair...

Page 118: ...FS900 Main body Page 6 20 Inspection and repair of each section...