AUI BP-9000E Owner's Manual

- 28 -

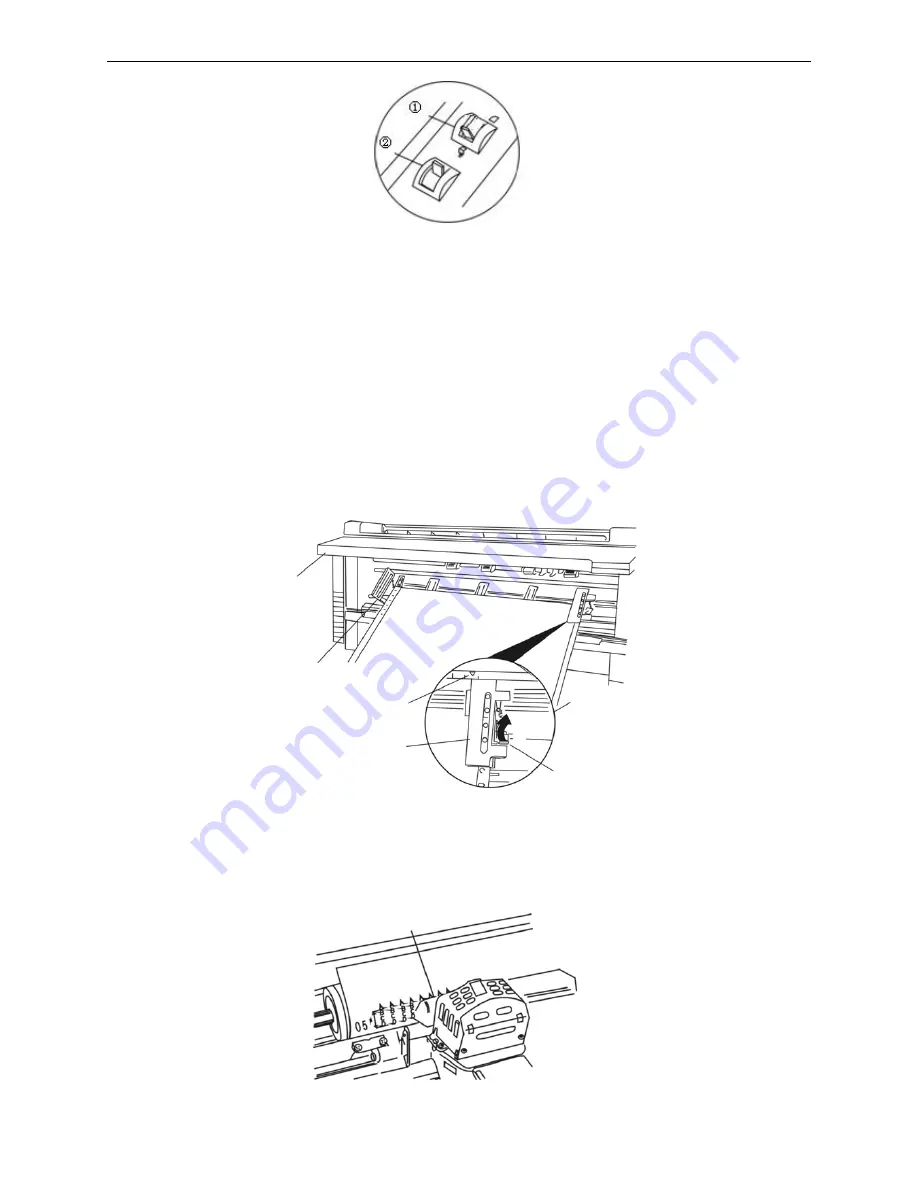

2. Adjust gap adjust lever

②

. In most time, pull the gap adjust lever to graduation 1 when using cut

sheet paper.

3. Remove or open the top rear cover

③

, stop it in the open position.

4. Loosen the tractor lock lever

④

(upwards), slide the right tractor to the Figure shown position.

5. Open the tractor cover

⑤

, install fanfold paper, and then close the tractor cover carefully.

Note: When closing the tractor cover, be careful or it may pinch your fingers.

6. After installing the paper, adjust the left tractor to the proper position to make the paper flat (do

not stretch the paper too tightly).

7. Press

PARK

key or

FF

key to feed paper.

8. When the distance between printing position and paper edge is 7 lines, pinch roller will go down

and press against the paper automatically.

4.3 Print position

Current print position

The current printing line (DDD…) is the third line from the top of the carriage guide (line spacing is

6LPI).

Carriage guide

⑤

Left tractor cover

④

Tractor lock lever

③

Rear cover

Do not stretch it

too tightly

Left blank mark

Right tractor

Loosen direction

⑤

Tractor cover

Summary of Contents for bp-9000e

Page 1: ...24pin Dot Matrix Printer OWNER S MANUAL BP 9000E ...

Page 32: ...AUI BP 9000E Owner s Manual 26 5 Press key to exit the MENU SETUP MODE BIN EXIT SETUP ...

Page 74: ...AUI BP 9000E Owner s Manual 68 Sample 2 Envelope Rear view ...

Page 80: ...AUI Co Ltd 16 19 NIHOMBASHI KODEMMA CHO CHUO KU TOKYO 103 0001 JAPAN ...