19

E

ngl

is

h

M/

Q1

M/

Q3

T/Y

10

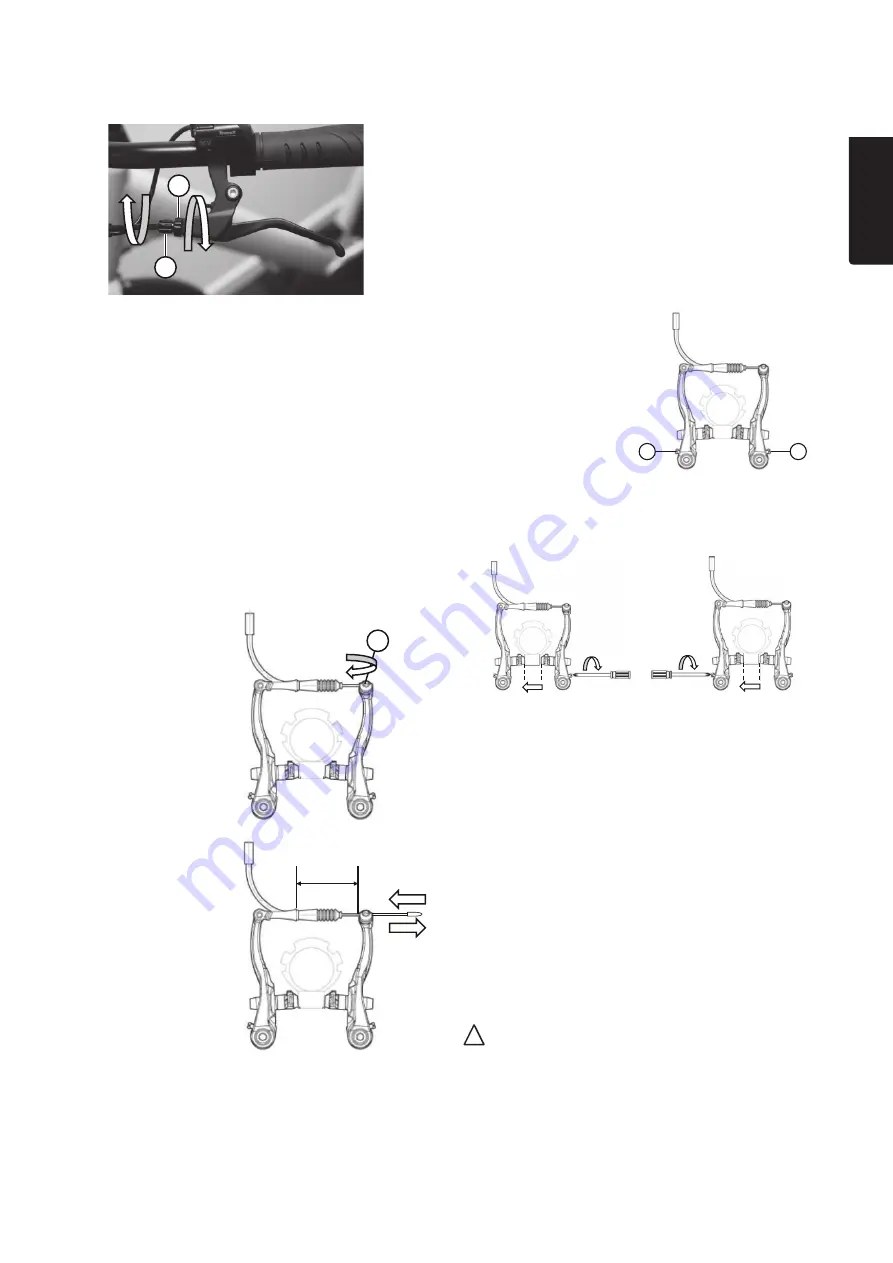

50-65 mm

T/Y2

T/Y2

For

minor

adjustments, you can turn the brake lever

adjustment screw (M/Q1) for cable tension.

The brake arm spring tension

• The brake arms are spring-loaded, which means that

they are pushed outwards away from the rim when

the brake lever is not pulled.

• The tension of the spring-loading must be the same

for both brake arms in order to ensure that the braking

force and the distance between the brake pads and

the rims is equal on both sides.

• The braking system works most effectively when

the force of the brake arms’ spring-loading is as low as

possible while also being fully adequate for the brake

arms to spring outwards, without obstruction, when

you release the brake lever.

1. Turn the locking ring (M/Q3) against

the adjustment screw.

-

Turn the adjustment screw (together with

the locking ring) outwards/anti-clockwise to

increase the cable tension. The distance between

the brake pads and wheel rims becomes smaller.

The brake lever moves away from the handlebars.

-

Turn the adjustment screw inwards/clockwise to

decrease the cable tension. The distance between

the brake pads and wheel rims becomes greater.

The brake lever moves closer to the handlebars.

2. Finally, tighten the locking ring against the brake lever

in order to fix the position of the adjustment screw.

If

greater

adjustments are required (which cannot be

achieved using the adjustment screw), you must adjust

the position of the brake cable (T/Y9) on the brake arm.

1. Hold the end of

the cable while you

loosen the socket

head screw (T/Y10)

(5 mm).

2. Pull the cable out

from the brake

arm to tighten

the cable, or push

in the opposite

direction to

loosen the cable.

The distance

between the cable’s

attachment to

the brake arm and

the link on the other

brake arm must be

50–65 mm.

3. Tighten the screw.

4. Finely-tune this adjustment as necessary, in

accordance with step 1.

• The tension of

the spring is adjusted

using a screw next to

the brake arm pivot

point (T/Y2).

1. Test the brakes repeatedly while observing both

the movement of the brake arms and the distance

between the brake pads and the rims. Test whether it

requires much or little force to pull the brake lever.

2. If the brake arms

move unevenly, or if

the brake pads are

at unequal distances

from the rim, turn

the adjusting screw

(in an anti-clockwise

direction) on the brake

arm that either moves

the most or whose

brake pad is furthest

from the rim.

3. If adjusting the screw in

accordance with step 2

does not result in any

change, you should turn

the adjusting screw (in

a clockwise direction) on

the brake arm that moves

the least or whose brake

pad is closest to the rim.

Test the brakes repeatedly

while turning the screw

in order to see the direct

results of the adjustment.

4. If the brake arms move evenly but you think that

the brake lever is stiff and hard to pull, try turning

the adjustment screws on both brake arms in an anti-

clockwise direction.

Note:

• Adjust the screws evenly on both sides until

the resistance of the brake lever decreases.

• Make sure that you do not loosen the screws so much

that they fall off. If you reduce the tension too much,

the brake arms will not spring outwards. If this happens,

turn the adjustment screws in a clockwise direction.

Summary of Contents for 31-9779

Page 2: ......