50

DE534A

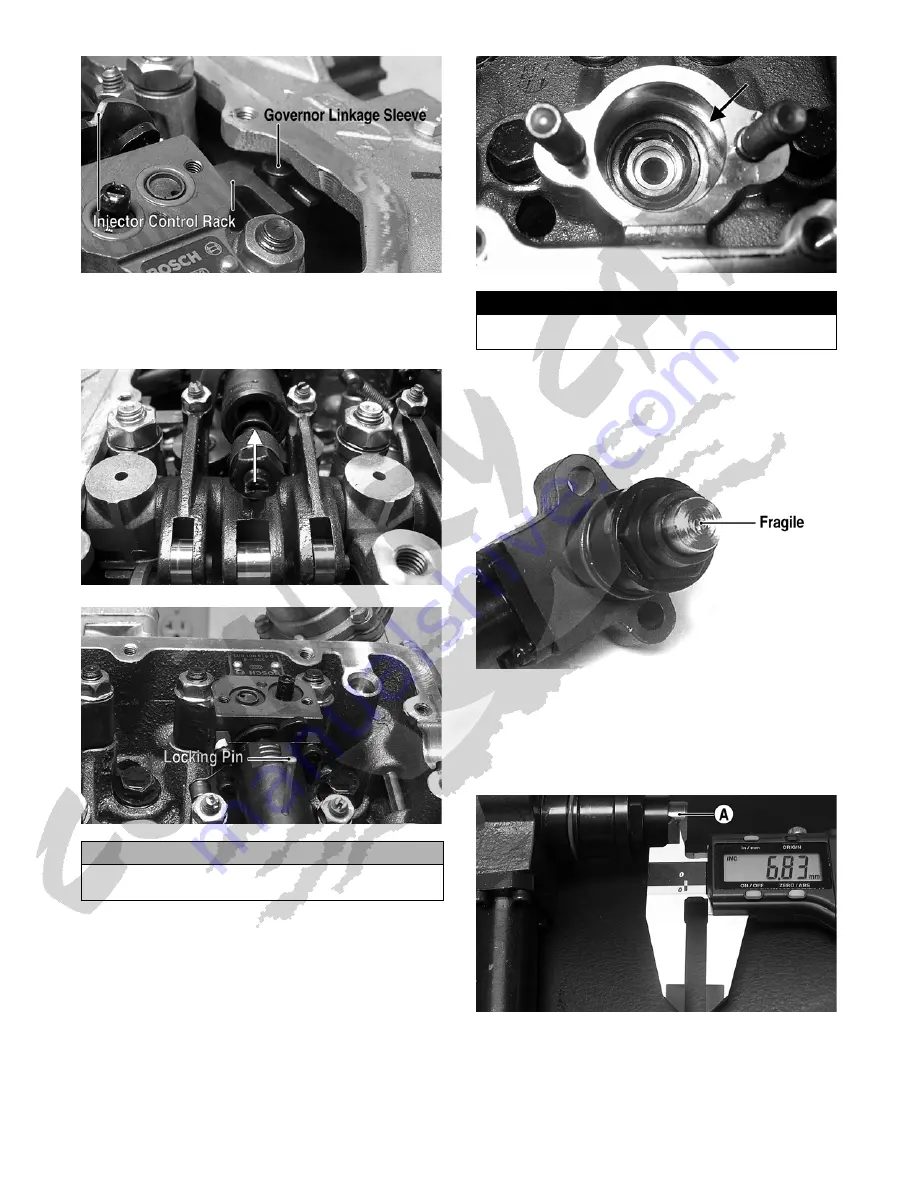

11. Rotate the engine until the injector lobe forces the

camshaft follower to its highest position; then insert

a hardened locking pin into the hole in the injector

pump barrel.

DE404A

DE329B

12. Repeat step 11 for the second injector. Account for a

flame washer and copper washer for each injector.

Servicing

Proper servicing of fuel injection components requires a

number of special instruments, special training, and an

extremely clean environment (clean room); therefore,

Arctic Cat recommends injector service be performed by

a qualified diesel injection service facility.

Installing

1. Thoroughly clean the injector bores in the cylinder

head; then dry with compressed air.

DE567A

NOTE: A small round wire brush can be used to

clean injector bores and seating surfaces.

2. Clean the unit injector with a soft wire brush being

careful not to damage the injector tip.

DE565A

3. Measure the injector nozzle protrusion (A). Measure-

ment should be 6.80-7.05 mm (0.268-0.277 in.).

Excessive protrusion may be corrected by installing

supplemental washers available in 0.25 mm (0.001

in.) sizes along with the standard copper washers

(B).

DE566A

CAUTION

DO NOT loosen the jam nut or the injector timing adjust-

ment screw. This will require timing the injector.

! WARNING

Always wear safety glasses when using compressed

air.