91

HELIX™ Manual

(P/N 26291)

Chapter 5: Inspection & Maintenance

Rev A (February 2018)

HELIX™ PCU

Fire Suppression System

•

Perform the monthly inspection procedure.

•

Verify that hazards have not changed. Look for changes in operation or cleaning procedures

that may have increased the hazard. Compare with the original PCU analysis.

•

Inspect the Agent Cylinder(s) and Nitrogen Cylinder(s) on systems so equipped. If Pressure

Gauge is bent or damaged, depressurize Cylinder(s) and replace. Clean Cylinder(s) to

remove dirt, grease and foreign material. Make sure that instruction nameplates are securely

fastened and legible. Inspect the Cylinder(s) for corrosion, abrasion, and dents or damage.

Replace Nitrogen Cylinder(s) with new ones and hydro

-

test Agent Cylinder(s) if any of these

conditions are found. If Agent Cylinder(s) are found to be faulty, replace.

•

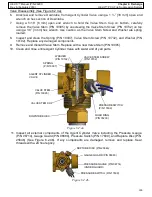

Remove and inspect control heads for damaged, missing, or substituted parts. Instructions for

control head (P/N 10147

-

R or 14032

-

R) disassembly, cleaning and reassembly can be found

in Chapter 6.

•

Inspect and clean the top of the Agent Cylinder Valve.

•

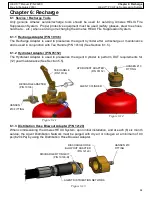

Disconnect Discharge Fitting Kit from Agent Cylinder Valve (

make sure that actuation

method(s) are removed or disabled when performing this step!

). Inspect Agent Cylinder

Valve discharge port for contaminants and clean if necessary. Note: Chemical residue found

in the Agent Cylinder Valve discharge port can be a sign of an unreported system discharge.

If a system has discharged, go to appropriate section for recharge procedures in Chapter 6.

•

Examine the Agent Distribution Network. Look for signs of wear or chafing on network hoses.

Replace

any damaged hose sections.

•

Examine Nozzles (P/N 26330) and protective Dust Caps (P/N 10167). If protective Dust Caps

are missing from Nozzles, re

-

install new ones.

•

Purge the Agent Distribution Network with air or nitrogen only (See Section 6.2.2).

•

If a Pneumatic Actuation Network is used, unscrew Nitrogen Cylinders from actuators. Cycle

each actuator several times verifying free travel of Puncture Stem Assembly inside each

actuator. If any defects are found, rebuild actuator (See Section 6.2.7). Verify that the

Pneumatic Actuation Network is functioning properly by performing the Pneumatic Actuation

Network Testing (See Section 6.2.8).

•

Replace the batteries in accordance with the replacement procedure per Section 5.6

.

Also, perform a commission test of the system as described in Section 4.11. The batteries

currently installed may be used for this commission testing, since the primary battery will be

replaced.

Warning: Do NOT perform the commission tests on the system until all

Linear Actuators (P/N 20500

-

R) are replaced with Fire Alarm Modules (P/N 23651).

Otherwise, a system discharge may result!

•

Document all work completed during service for record retention. Disclose any anomalies and

deficiencies to the property owner for corrective action requirements.

5.4 (6) Six Year Maintenance: AUTHORIZED AMEREX TECHNICIAN

•

Perform semi

-

annual inspection.

•

Per NFPA 17 guidelines, stored pressure Dry Chemical Agent Cylinders must be de

-

pressurized for inspecting the inside of the Agent Cylinder and the Agent. Agent must be free

flowing. Inspect Agent Cylinders for damage, dents, abrasions or corrosion. If any of these

conditions are found, replace the Agent Cylinder. See Chapter 6 for recharge instructions.

•

Inspect the inside of adapters and hose end fittings of the Agent Distribution Network(s) and on

so equipped Pneumatic Actuation Network(s). Replace any corroded adapters and hose end

fittings.

•

Replace Linear Actuators if in service for 6 years.