8

HELIX™ Manual

(P/N 26291)

Chapter 2: System Components

Rev A (February 2018)

HELIX™

PCU Fire Suppression System

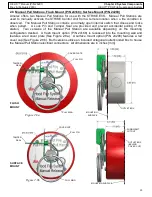

WARNING: SHIPPING PLATES (FIGURE 2.1a) WILL BE REMOVED AT INSTALLATION AND

RETAINED FOR

LATER USE. DO NOT REMOVE UNTIL DIRECTED TO DO SO.

Agent Cylinders are constructed to meet DOT 4BW, requirements with test pressure of 700 psi

(4826 kPa), and require a hydrostatic test every twelve (12) years or more frequent intervals if

warranted. The operating temperature range of the Agent Cylinders is

-

65°F to 150°F

(

-

54°C to

66°C).

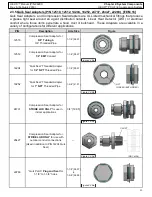

Agent

Cylinder

Part

Number

Overall Height

(A)

in (mm)

Height to Discharge

Opening (B)

in (mm)

Diameter (C)

in (mm)

Agent

Capacity

lb (kg)

HX25ABC PRS SW

26318

17.6 (447)

16.0 (406)

9.0 (229)

25 (11.3)

HX50ABC PRS SW

26320

31.3 (795)

30.0 (762)

9.0 (229)

50 (22.7)

Table 2.1

Figure 2.1b

ANTI

-

RECOIL

PLATE (P/N 10646)

SHIPPING PLATE (P/N 10099)

PRESSURE GAUGE

AGENT CYLINDER VALVE

RUPTURE DISC

(UNDER CAP)

DUST CAP

(P/N 25685)

AGENT CYLINDER

PRESSURE SWITCH

2.1 Agent Cylinders

The Amerex HELIX Fire Suppression System Agent Cylinders are available in two sizes, with

different mounting options and orientations. The Agent Cylinders are shipped fully charged from the

factory. Each Agent Cylinder includes a brass Agent Cylinder Valve with a Pressure Gauge and a

safety Rupture Disc with an installed Dust Cap installed. Agent Cylinders are pressurized with

nitrogen gas to a pressure of 350 psi (2413 kPa) at 70°F (21°C). HX25 and HX50 Agent Cylinders

are equipped with an Anti

-

Recoil Plate (P/N 10646) installed on the Agent Cylinder Valve discharge

outlet to prevent accidental discharge and to minimize recoil in the unlikely event of an accidental

discharge during shipment. (See Figure 2.1a). These safety components are removed only when the

Agent Cylinder is installed in the Cylinder Bracket and connected to Agent Distribution Network.

DISCHARGE

OPENING

Figure 2.1a

DISCHARGE OPENING

HX25ABC

HX50ABC