56

HELIX™ Manual

(P/N 26291)

Chapter 4: System Installation

Rev A (February 2018)

HELIX™ PCU

Fire Suppression System

4.7.3 Linear Heat Detector (LHD) Installation (P/N 24744

-

XX)

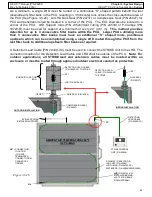

The Linear Heat Detector (LHD) is a preset (356ºF/180ºC) heat sensing device capable of sensing

an overheat condition at any point along its routed path. All LHDs must be installed in accordance

with the following instructions:

•

Each LHD must be supported using Amerex supplied LHD Support Clips and Support Tubing

(P/N 16501/23524 Clips; P/N 24539 Tubing) or P

-

Clamps (P/N 18720

-

R). The LHD must be

supported a minimum of every 24” (0.61 m). A support is also required within 3” (0.07 m) of an

EOL

Module connected to the end of an LHD (See Figure 4.7.3a).

•

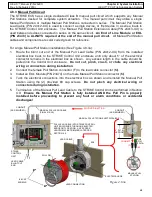

Any LHD penetration through a PCU or bulkhead requires the use of an LHD Quik Seal (P/N

24737) or Compression Seal (P/N 26427) (See Section 4.7.5).

•

LHDs are supplied with an uninstalled connector on a single end to facilitate installation through

any LHD Penetration Seals. After this end of the LHD is installed through all LHD Penetration

Seals or if no Seals are required, the included connector and connector lock must be installed

on the end of the LHD (See Section 4.7.6). Only then can an EOL or additional detection

devices be installed.

•

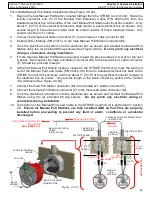

As a minimum, a single LHD must be routed in a continuous “S” shaped pattern behind the last

(downstream) filter bank in the PCU, resulting in 3 horizontal runs across the cross sectional

area of the PCU. (See Figure 4.7.3)

•

The LHD wire must NOT be installed within any hazard area that exceeds 250°F (121ºC) during

normal operating conditions. Physical contact with any high heat surfaces exceeding 250°F

(121ºC) is not permitted.

•

The LHD must NOT be obscured by supports or support structures and should be fully exposed

to air passing through the PCU to ensure rapid detection.

•

The LHD must be installed in areas where potential damage resulting from normal appliance

operation, moving parts, or access openings will not occur. The LHD must not interfere with

routine appliance maintenance or filter changes.

•

The LHD cannot be chafed, cut, bent or crushed.

•

Selection of the LHD length should be such that it adequately covers the hazard area but is not

excessively long, reducing the potential of damage.

•

The LHD must be installed in the detection circuits only and a single circuit must not exceed 100

feet (30.5 m).

•

The LHD must NOT be installed taut without strain relief. The LHD must NOT be crimped,

pinched or bent beyond its minimum bend radius of 2 ½” (0.06 m).

A typical LHD installation is shown on the following page. An

EOL Module must be installed on the

end of the LHD (after the LHD connector is installed per Section 4.7.6). This EOL may be located in

a corner, inside the PCU (See Figure 4.7.3a). If additional LHDs are to be installed in series,

downstream of the first LHD, a second LHD Penetration Seal must be

installed on that side of the

PCU, with any additional connections to the LHD located on the outside of the PCU.