20 Gear Drive, Plymouth Ind. Park, Terryville, CT 06786

Tel: (860) 585-1254 Fax: (860) 584-1973 http://www.amci.com

27

CHAPTER 3

A

DDITIONAL

F

UNCTIONALITY

Brake Monitor

For press applications, the ANS1 has a

Brake Monitor

. Before the Brake Monitor can be used, it has to be

associated with one of the sixteen available inputs. The Brake Monitor reports the positions where the brake

input was released and applied as well as the starting and stopping times of the press.

Outputs can also be assigned to the Brake Monitor and signal when the starting or stopping times of the press

exceed programmed limits. These outputs will switch from active to inactive if a fault occurs.

Stop Time Monitoring

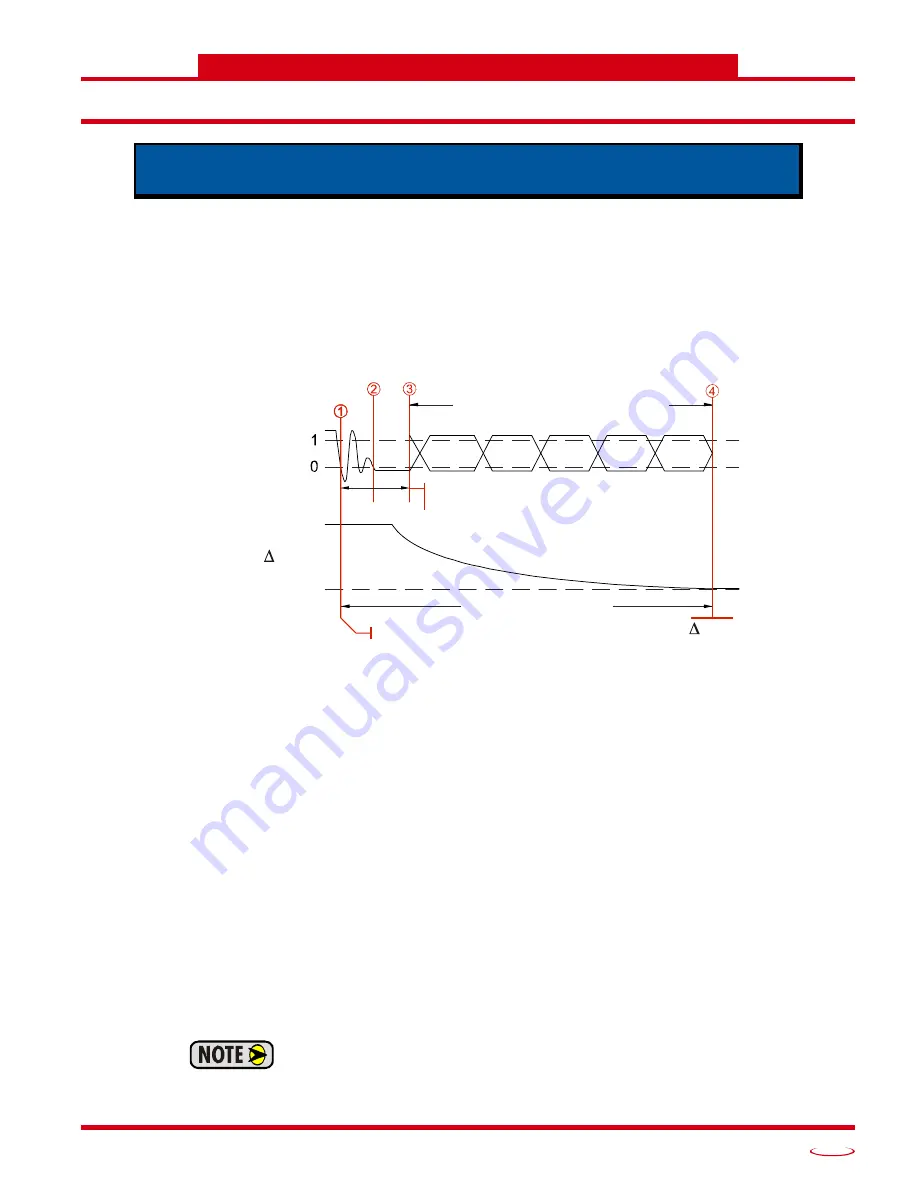

Figure 3.1 Stop Time Monitor

1) The ANS1 captures the

Brake Applied Position

and starts the Stop Time Timer when the Brake Input

makes an active-to-inactive (1

0) transition. The Brake Applied Position is not immediately placed

in the input data. It is updated when the brake cycle completes.

2) Sixteen milliseconds after the initial transition, the ANS1 begins to check the state of the input every

millisecond. If the Brake Input returns to its “brake removed”, (active), state for eight milliseconds in

the next sixteen, the input transition is considered noise and the brake cycle is aborted. The next

transition on the Brake Input starts another brake cycle.

3) At the end of an additional sixteen milliseconds, (thirty-two milliseconds total), the stored states of

the input are checked. If the Brake Input is not in its “brake applied”, (inactive), state for twelve of

the last sixteen milliseconds, the input transition is considered noise and the brake cycle is aborted. If

the input is in its “brake applied” state at the end of the thirty-two milliseconds, the brake cycle

debounce steps will begin again immediately. If the input is in its “brake removed” state, the brake

cycle will start on the next transition.

Once the debounce time is exceeded, the state of the brake trigger is ignored until the brake cycle

is complete. From this point on, the Stop Time timer runs until the transducer position stops

changing. The ‘

Position’ section of the diagram shows the press coming to a stop.

4) The programmable

Complete Stop Count

parameter value is used to determine when the transducer

has come to a stop. The transducer is considered stopped when the change in position in 125

milliseconds is less than the programmed Complete Stop Count parameter value.

The Complete Stop Count parameter is always based on 4,096 counts per turn. It is

not affected by the

Counts per Cycle

and

Full Scale Count

parameters.

This chapter covers the additional functionality supplied by the ANS1. This

includes brake monitoring, die protection, and production counters

Brake

Input

Debounce Time

Brake Trigger Input = 32 mSec

Measured Stop Time

Brake Applied Position

Position

P = 0

Input State is 'Don't Care' from the end of the

Debounce Time until press has stopped.

Summary of Contents for ANS1 ANYNET-I/O

Page 1: ...MICRO CONTROLS INC ADVANCED U s e r M anual Manual 940 0A090...

Page 6: ...Table of Contents ADVANCED MICRO CONTROLS INC 6 Notes...

Page 26: ...Limit Switch Functionality ADVANCED MICRO CONTROLS INC 2 26 Notes...

Page 36: ...Additional Functionality ADVANCED MICRO CONTROLS INC 3 36 Notes...

Page 90: ...LEADERS IN ADVANCED CONTROL PRODUCTS ADVANCED MICRO CONTROLS INC...