8

Preparing the AUET for Use

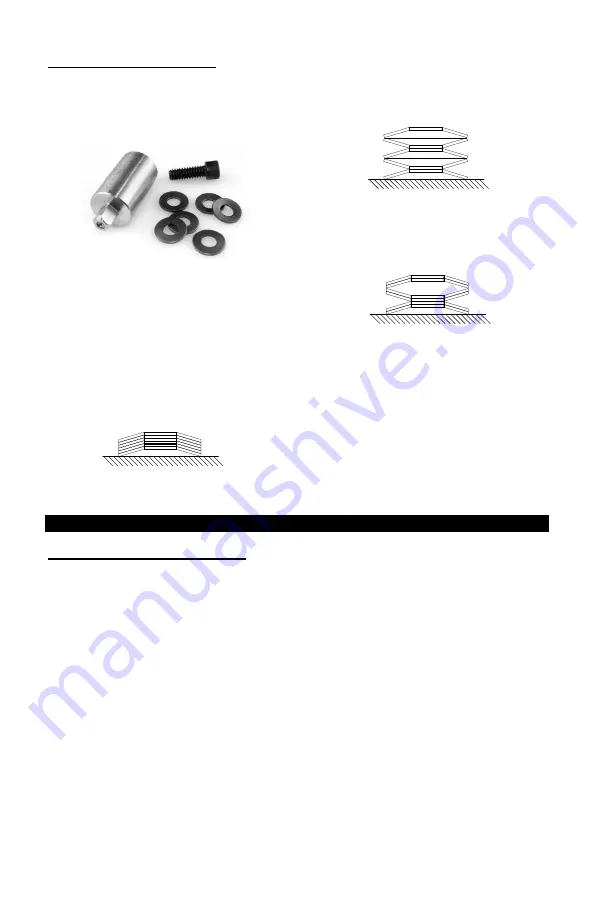

The

AUET

testers feature a supplied

Joint

Simulator

(

Fig. A

) that is configurable to a

wide variety of joint conditions.

Fig. A

The Joint Simulator is made up of a series

of

Belleville Washers

that allow the user

to pre-configure the joint to match the

actual application joint as closely as

possible. Each of the

Belleville Washers

is concave in shape. By aligning all the

concave curves in the same direction a

simulated hard joint is achieved (

Fig. B

).

Fig. B

Alignment of the concave shapes in an

opposing manner a simulated soft joint is

achieved (

Fig. C

).

Fig. C

Differing combinations allow for simulated

medium joints to be achieved (

Fig. D

).

Fig. D

Joint kits can be adjusted by loosening the

Hex Screw

and aligning the stack of

Belleville Washers

according to your joint

condition needs. Hand thread the

Hex

Screw

into the housing several threads.

Place the square drive end of the

simulator into the female square drive on

the

AUET

Tester.

BASIC FUNCTIONS

OPERATING MODE Descriptions

By selecting the proper

Operating Mode,

the user can properly take torque readings

from a variety of manual and powered

tools.

PEAK

This mode will provide a display of the

maximum torque value achieved by

the tool during operation. This mode is

used for all continuous drive tools

impact or impulse tools, dial wrenches

and to identify highest torque delivered

with click type wrenches.

1

st

PEAK

This mode will detect and display the

“first peak” achieved by click wrenches

and cam-over screwdrivers.

PULSE

This mode counts the number of

events (pulses or impact blows) in a

cycle. This mode does not change the

manner in which peak torque is

identified.

TRACK

This mode will display torque in real-

time as it is applied to the connected

transducer. Track mode is used

primarily for calibration of the unit or

identifying the condition of the

transducer. In Track Mode with no

torque on the transducer, the display

should show zero.