GeoSteer®

21

PN 2006410—ENG Rev. B

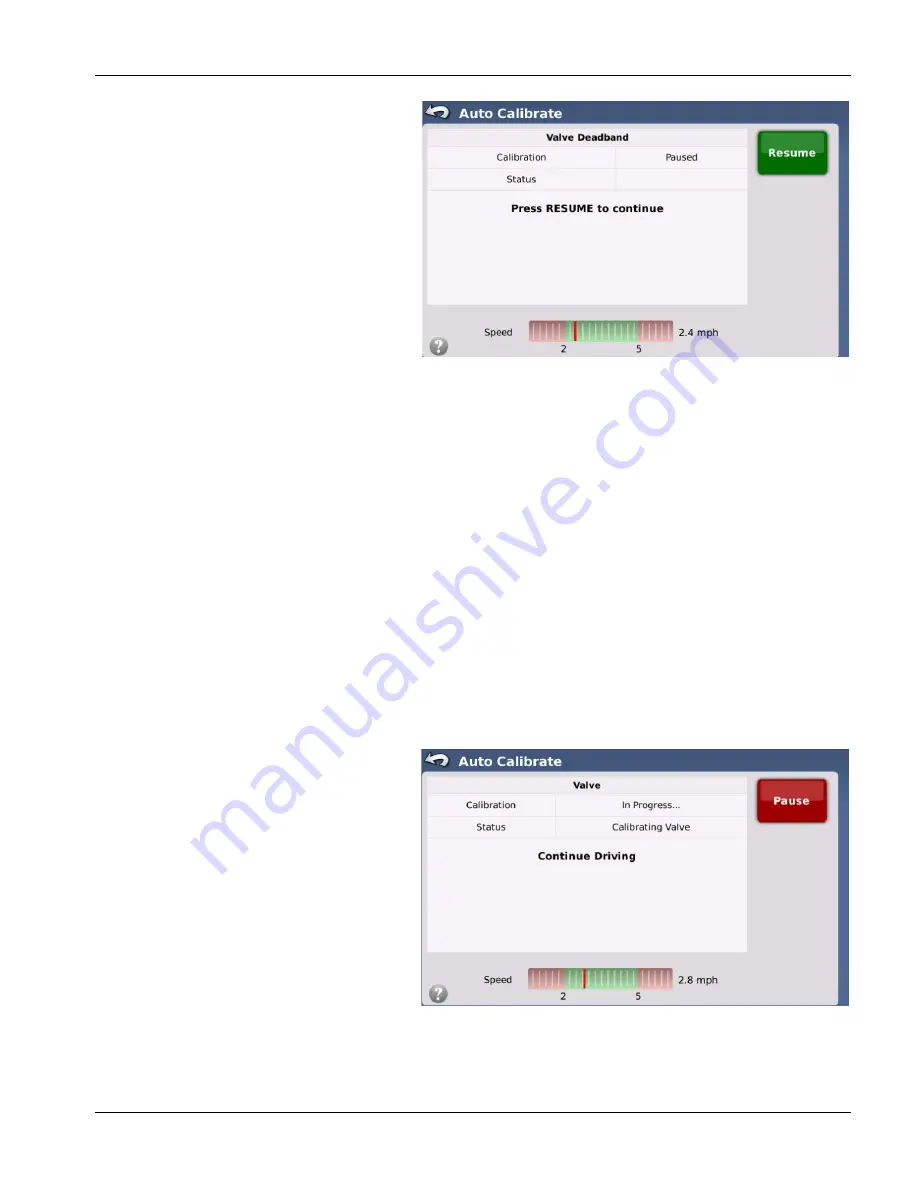

Valve Deadband

Oil flow is proportional to voltage or pulse width

signal changes sent from control unit. It takes a

certain minimum amount of signal to start oil flow

through valve. If signal is below that minimum

amount, no oil flows and steering axle will not

move. Voltages or pulse widths where there is no

valve movement is called Deadband. Deadband is

detected by incrementally increasing signal sent to

valve in both directions until Control Unit detects

motion from Wheel Angle Sensor.

To begin Valve Deadband calibration, drive vehicle

in a straight line between 2.0 and 5.0 mph (3.2 and

8.0 k/h) and then press Resume button to start

calibration process. Vehicle will continue to drive in

a straight line for a time. Eventually, steering axle

will begin to move to both sides. Once this

happens system will have determined deadband

for valve and move on to next step.

Angle Sensor

Control Unit reads value of Angle Sensor to determine position of steering. During calibration process, Control Unit holds

Angle Sensor at different positions from full left to full right and measures actual change of heading at each position using

the GPS antenna. At the conclusion of calibration, Control Unit can determine expected change of heading for any Angle

Sensor position. It is also able to determine exact Angle Sensor reading that should steer vehicle in a straight line.

÷

NOTE!: For next step in calibration process, vehicle will turn full left and full right. Make sure all objects are clear of

area where calibration is taking place.

Angle Sensor calibration should start automatically once Valve Deadband has been determined. If it does not, press

Resume button to start calibration process. Steering axle will make a hard turn to one direction and then back to opposite

direction to find maximum Angle Sensor stops. System will then reposition Angle Sensor at regularly spaced increments

between two maximum positions and measure change of heading at each position. System will work from one direction,

making increasingly less sharp turns, then continue past straight ahead position, and then start making increasing sharp

turns in opposite direction. It will then repeat process in opposite direction. Once this is completed, calibration process will

move on to next step.

Valve

Valve calibration measures rate of turn using Angle

Sensor when a signal command is sent to Steering

Valve. As signal to valve is increased, rate of turn at

Angle Sensor increases. Control Unit takes readings

of Angle Sensor rate of turn at different signal

commands so system knows how fast vehicle will

turn at any signal command sent to Steering Valve.

Valve calibration should start automatically once

Angle Sensor calibration has finished. If not, press

Resume button to start calibration process. First

step of this calibration procedure will be to

determine maximum rate that steering axle can be

turned using Steering Valve. System will command

vehicle to turn steering axle to one direction at

maximum signal and then to opposite direction at

maximum signal. It repeats this process two more

times.