Refitting the rectangular rails

Use this procedure to refit the rectangular rails.

Refitting the rectangular rail

Note

Action

Rail pressing tool:

•

Rack side: 3HKA00000189983

•

Non-rack side: 3HKA00000189982

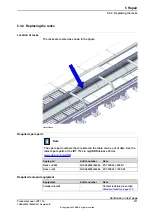

xx2200001178

Refit the rectangular rail with the rail

pressing tool.

Note

Use the rail pressing tool to make sure that

the rails are pushed against the side

member mounting surface.

Note

There should be no gap between the rail

mounting surface and the section mounting

surface.

1

Fit with the screws, loose tightening.

2

xx2200001185

Visually check if the rails are seamlessly

connected.

Note

If there is seam existed, push to adjust rail

and ensure that the gap of seam is 0.2 mm

on each side and totally no more than 0.4

mm.

Otherwise, change with a new rail.

3

Press the rail with the rail pressing tool to

ensure that there is no gap between the

rail with the lower surface of the track step.

4

Screws:

Slightly tighten the rail screws and finalize

the horizontal alignment of the IRT 710 as

described in

5

For 0.5 m ISO 4762 M12x55 Class12.9 (7

pcs)

For 1 m ISO 4762 M12x55 Class12.9 (12

pcs)

For 1.5 m ISO 4762 M12x55 Class12.9 (15

pcs)

Tightening torque: 128 Nm ±3%

Continues on next page

Product manual - IRT 710

269

3HKA00000186299-001 Revision: B

© Copyright 2023 ABB. All rights reserved.

5 Repair

5.3.2 Replacing the rectangular rails

Continued

Summary of Contents for IRT 710

Page 1: ...ROBOTICS Product manual IRT 710 ...

Page 14: ...This page is intentionally left blank ...

Page 58: ...This page is intentionally left blank ...

Page 84: ...This page is intentionally left blank ...

Page 360: ...This page is intentionally left blank ...

Page 364: ...This page is intentionally left blank ...

Page 378: ...This page is intentionally left blank ...

Page 380: ...This page is intentionally left blank ...

Page 383: ......