Electrical installation

58

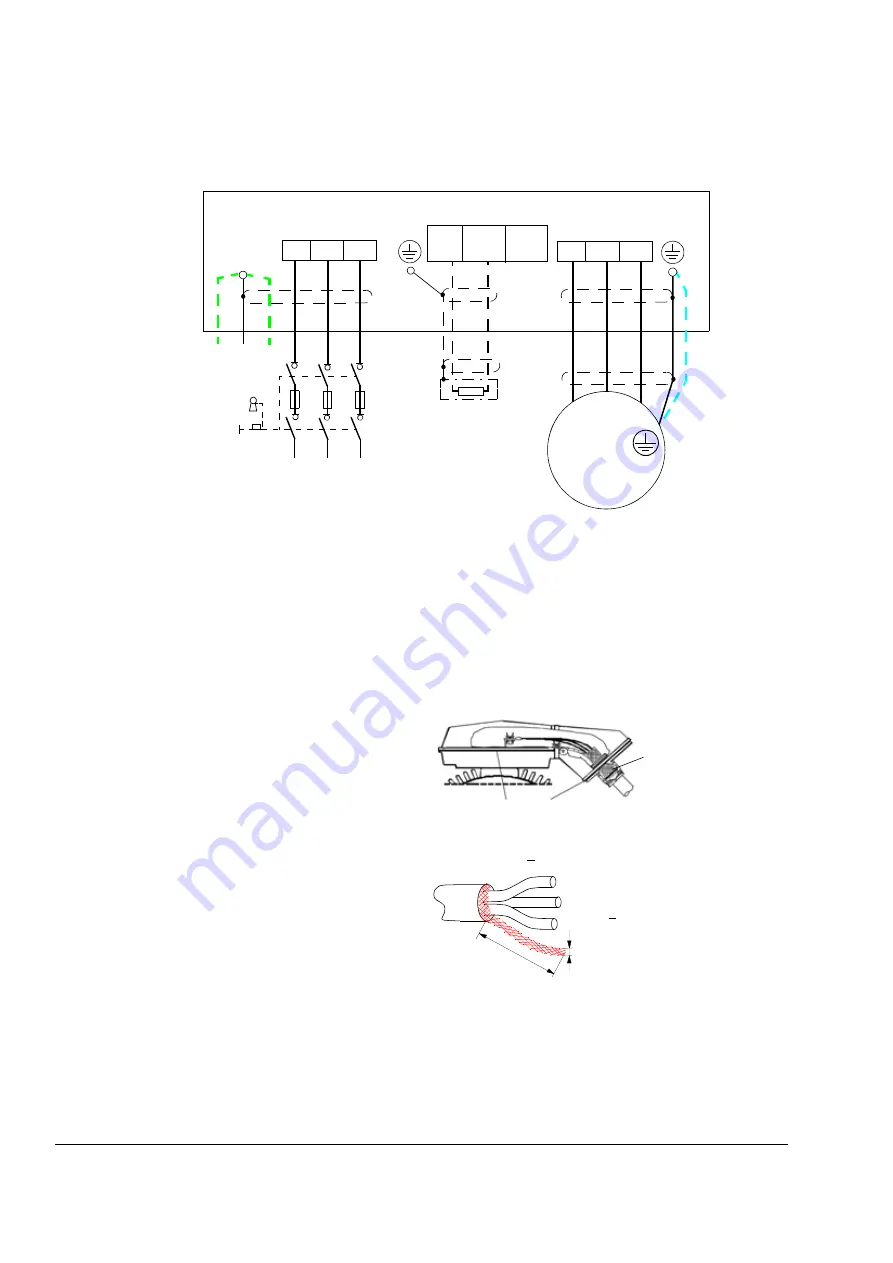

Power cable connection diagram

INPUT

OUTPUT

U1 V1 W1

1)

U2 V2 W2

UDC+

R+

UDC

-

R

-

L1

L2

L3

(PE)

(PE)

PE

2)

Drive module

PE

* For alternatives, see

Planning the electrical

installation

*

Grounding of the motor cable shield at the cabinet entry

Ground the cable shield 360 degrees at the lead-through of the

cabinet.

Grounding of the motor cable shield at the motor end

For minimum radio frequency interference:

• ground the cable shield 360 degrees at the lead-through of

the motor terminal box

• or ground the cable by twisting the shield as follows:

flattened width > 1/5 · length.

360 degrees grounding

Conductive gaskets

a

b

b > 1/5 · a

1), 2)

If shielded cable is used (not required but

recommended) and the conductivity of the shield is

< 50 % of the conductivity of the phase conductor,

use a separate PE cable (1) or a cable with a

grounding conductor (2).

Ground the other end of the input cable shield or PE

conductor at the distribution board.

3) 360 degrees grounding recommended at the cabinet

entry if shielded cable

4) 360 degrees grounding required at the cabinet entry

in first environment installations **

5) Use a separate grounding cable if the conductivity of

the cable shield is < 50 % of the conductivity of the

phase conductor and there is no symmetrically

constructed grounding conductor in the cable (see

Planning the electrical installation

).

Note:

If there is a symmetrically constructed grounding

conductor in the motor cable in addition to the

conductive shield, connect the grounding conductor to

the grounding terminal at the drive and motor ends.

Do not use an asymmetrically constructed motor cable.

Connecting its fourth conductor at the motor end

increases bearing currents and causes extra wear.

External brake

resistor

3)

4)

U1

V1

W1

3

~

Motor

5)

4)

**

First environment EMC compliance is defined in

Summary of Contents for ACS800-04

Page 4: ......

Page 12: ...Safety instructions 12 ...

Page 54: ...Planning the electrical installation 54 ...

Page 72: ...Motor control and I O board RMIO 72 ...

Page 116: ...Resistor braking 116 ...

Page 117: ......