0.4VDC indicates the starter is an A style Solid State Starter and the microprocessor reads channels

1 through 7.

In the Solid State Starter, channel 0 indicates the starter size (model) and voltmeter range (300VAC

or 600VAC). Channel 1 is a hardware generated 100% FLA (prevents pre-rotation vanes from further

opening) or 104% FLA (closes pre-rotation vanes until motor current is less than 102%) current

limit override command that overrides normal Pro-rotation Vanes control. Channels 2 through 4

are analog voltages that represent phase A, B and C motor current. The highest phase is Channels

5 through 7 are analog voltages that represent phase A, B and C Line Voltage. The data for each

channel is shown on the below.

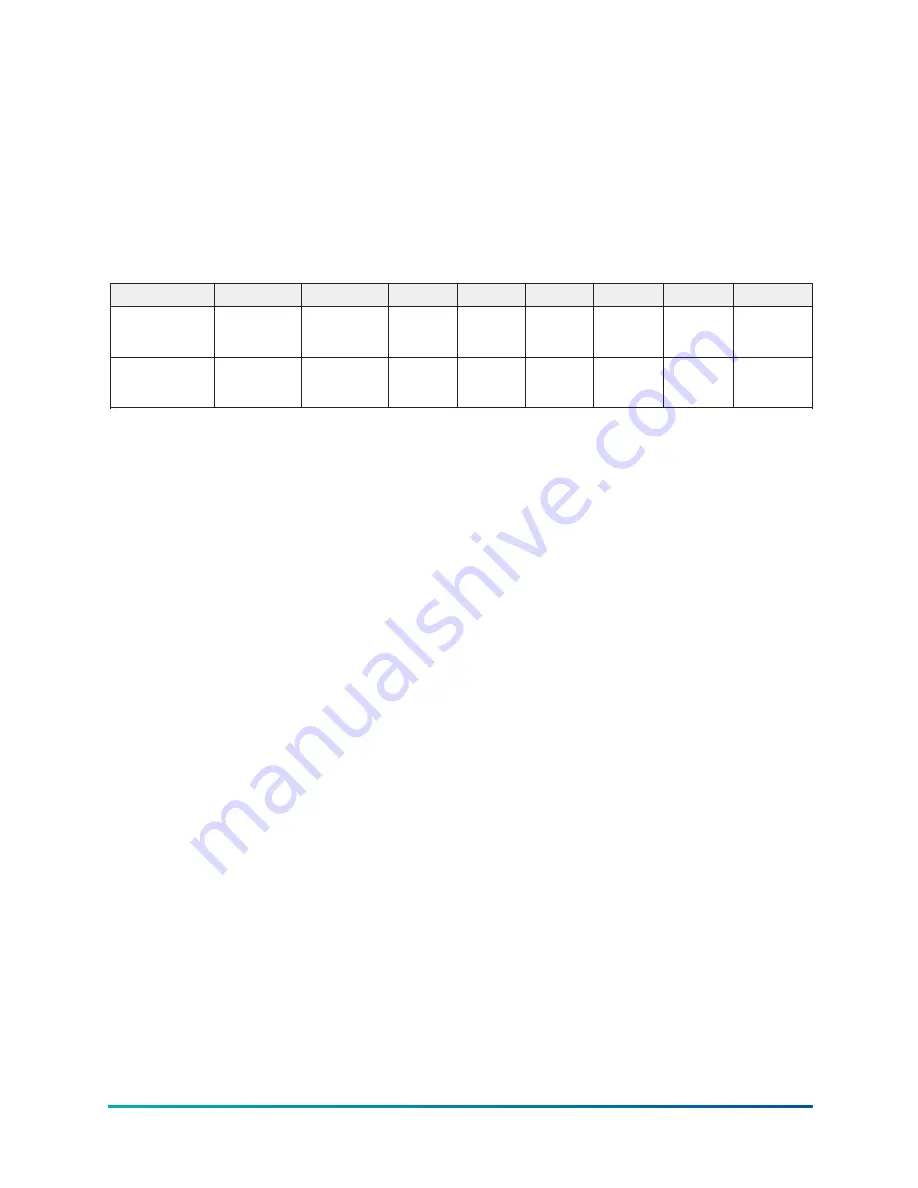

Table 211: Multiplexer channels

0

1

2

3

4

5

6

7

CM-2

GND

GND

GND

GND

GND

GND

GND

Peak Motor

Current

(%FLA)

Style A SSS

Starter model/

voltmeter

range

Current limit

command

Phase C

motor

current

Phase B

motor

current

Phase A

motor

current

Phase A

line voltage

Phase B

line voltage

Phase C

line voltage

Style B SSS interface

Style B Solid State Starters produced before June 2008 can communicate with the 031-03630-007

Microboard via the Opto-coupled COM5 serial data port (J15) using YORK proprietary protocol. The

serial data is represented by +5VDC and 0VDC logic levels. TX data to the starter is at J15-1. RX data

from the starter is at J15-2.

Style B Solid State Starters produced after mid 2008, communicate with the 031-03630-007

Microboard via the COM 2 serial port (J13) using RS-485 Modbus protocol. The COM 2 Modbus

communications may use the fiber optic interface for better noise immunity and elimination of

potential ground loop problems when the Solid State Stater is equipped with the compatible 02505

Logic/Trigger control board.

When SSS-Mod B is selected as the motor drive type on the SETUP Screen, additional setpoints must

be entered on the screen. The appropriate serial port (COM 2-Modbus or COM 5 YORK) must be

enabled using the Motor Communications Protocol setpoint. The selections are Modbus or “YORK”.

When Modbus is selected, the Motor Node ID setpoint must be set to match the setting of the

Starter Logic/Trigger Board Modbus Address Switch SW1. They must be both be set to “1”.

Variable Speed Drive interface

Variable Speed Drives produced before March 2007 communicate with Microboard 031-03630-007

via the Opto-coupled COM5 serial data port (J15) using the YORK proprietary protocol. The serial

data is represented by +5VDC and 0VDC logic levels. TX data to the starter is at J15-1. RX data from

the starter is at J15-2.

Variable Speed Drives built after March 2007 communicate with Microboard 031-03630-007 via the

COM2 serial data port (J13) using RS-485 or fiber optic Modbus protocol.

With Microboard 031-03630-007 when “VSD-60Hz” or “VSD-50Hz” is selected on the SETUP Screen

as the Motor Drive Type, additional setpoints must be entered on this Screen. The appropriate

serial port (COM2-Modbus or COM5-YORK) must be enabled using the Motor Communications

Protocol setpoint. The selections are Modbus or “York”. When Modbus is selected, the Motor Node

ID setpoint must be set to match the setting of the VSD Logic Board Modbus Address Switch SW3.

They must be both set to “1”.

There are two different types of Modbus protocol used. Modbus ASCII for Mod D/Vyper and

Modbus RTU for Raptyr. When VSD – 60Hz or 50Hz is selected for the Motor Drive Type setpoint on

the SETPOINTS Screen, the microboard will poll on COM 2 alternating between the two protocols

until one of them responds or until an initialization fault occurs. Once a valid response is received

YK-EP Style B Centrifugal Chiller

248

Содержание YK-EP

Страница 2: ...2 YK EP Style B Centrifugal Chiller...

Страница 6: ...6 YK EP Style B Centrifugal Chiller...

Страница 227: ...Figure 72 Sample printout of Status 227 YK EP Style B Centrifugal Chiller...

Страница 228: ...Figure 73 Sample printout of Status cont YK EP Style B Centrifugal Chiller 228...

Страница 229: ...Figure 74 Sample printout of Setpoints 229 YK EP Style B Centrifugal Chiller...

Страница 230: ...Figure 75 Sample printout of Setpoints cont YK EP Style B Centrifugal Chiller 230...

Страница 231: ...Figure 76 Sample printout of Schedule 231 YK EP Style B Centrifugal Chiller...

Страница 232: ...Figure 77 Sample printout of a Sales order YK EP Style B Centrifugal Chiller 232...

Страница 233: ...Figure 78 Sample printout of a Sales order cont 233 YK EP Style B Centrifugal Chiller...

Страница 234: ...Figure 79 Sample printout of History YK EP Style B Centrifugal Chiller 234...

Страница 235: ...Figure 80 Sample printout of History cont 235 YK EP Style B Centrifugal Chiller...

Страница 236: ...Figure 81 Sample printout of a security log report YK EP Style B Centrifugal Chiller 236...

Страница 260: ...Figure 87 Microboard 031 03630 007 Figure 88 Program card 031 03601 002 YK EP Style B Centrifugal Chiller 260...