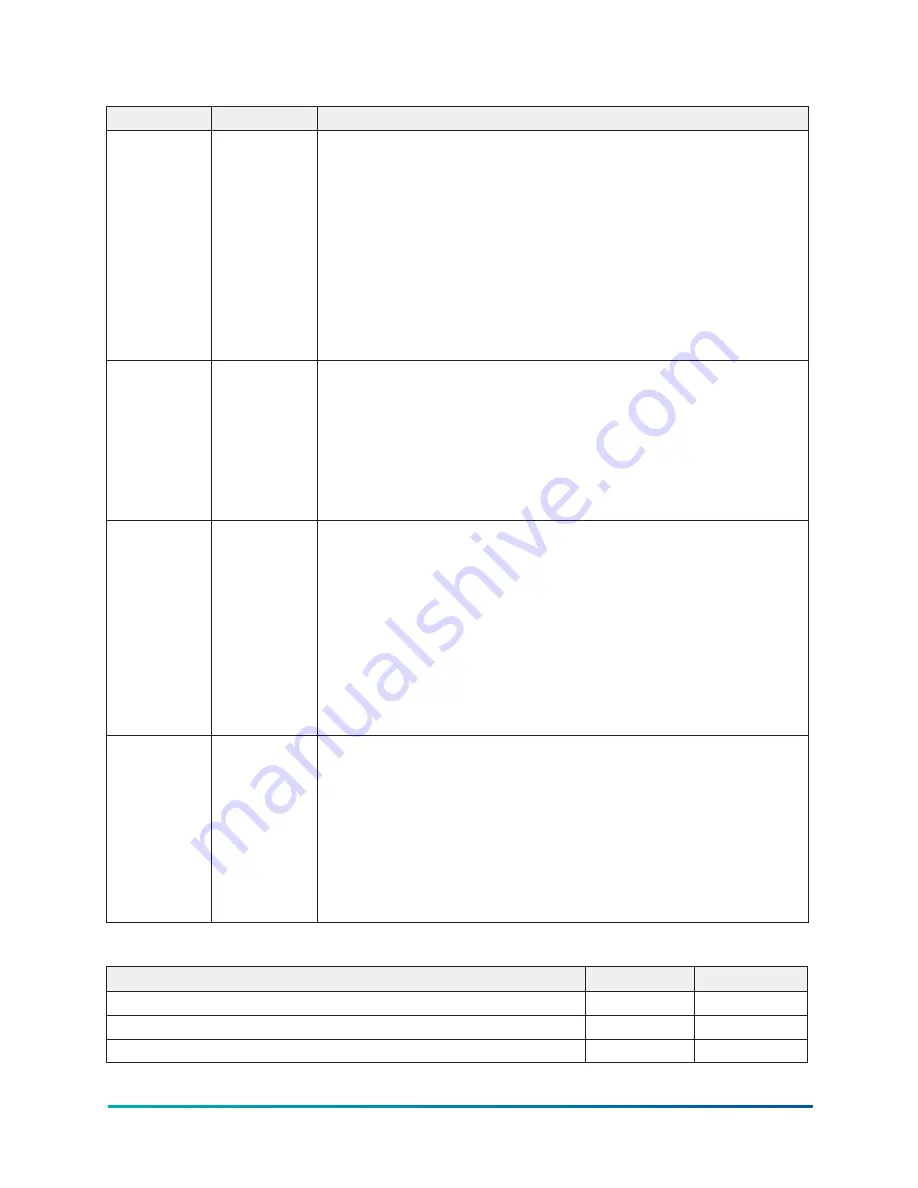

Table 141: Programmable

Button

Access level Description

Motor

Comm.

Protocol

Service

VSD and MVVSD applications – Should be set to Modbus.

Style B Liquid Cooled Solid State Starter and MVSSS applications –

Should be set to Modbus.

Only displayed when Motor Drive Type Setpoint above is selected

as “VSD-60 Hz”, “VSD-50 Hz”, “MVVSD”, “SSS-Mod B”or “MV SSS”.

Allows the Service Technician to enable the appropriate serial

communications port for communications with the Solid State

Starter (SSS) or Variable Speed Drive (VSD). The chiller must be

stopped with the Start-Run-Stop/Reset switch in the Stop/Reset

position to change this setpoint.

Coastdown

Time

Service

Only displayed when Standard is selected as the Coastdown

Setpoint. Allows Service Technician to select appropriate coastdown

time for compressor motor applied. Larger motors require a

longer coastdown time to assure the motor rotation has stopped

before the oil pump is turned off at completion of post-lube.

Programmable range is determined by the Chiller Style/Compressor

Setpoint (Style F/J7 and G/K6-K7, the range is 240 (default) to 900

seconds. All others, the range is 150 (default) to 900 seconds).

Condenser

Temperature

Range

Service

Special order R134a chillers are allowed to operate at higher than

standard condenser temperatures. The resulting higher operating

pressures require higher condenser warning and safety shutdown

thresholds than standard applications. These chillers are equipped

with a special High Pressure Cutout Switch (HPCO) that can be set to

trip at a higher pressure.

This setpoint allows for either standard or higher temperature

condenser temperature operation. It is set to Extended for those

chillers equipped for high condenser temperature operation.

Otherwise, it is set to Standard. For R134a chillers, refer to Table 142.

Motor Auto

Lube Type

Service

Set to None, QLS401, P203 or Sleeve as applicable:

•

None - User must manually lubricate the motor bearings.

•

QLS401 - Injects grease at the interval factory set in the

QLS401 system.

•

P203 - The OptiView panel controls the lubrication time

interval and also monitors the grease level.

•

Sleeve - Motors with sleeve bearings use a lubricating oil

which extends the time interval for bearing lubrication.

Table 142: Condenser temperature range

Setpoint

Standard

Extended

Warning – High Pressure Limit – Maximum allowable value (PSIG) 162.5

193

Condenser – High Pressure – Trip/reset threshold (PSIG)

180/120

200/140

Condenser – High Pressure Stopped – Trip/reset threshold (PSIG) 160/160

170/170

147

YK-EP Style B Centrifugal Chiller

Содержание YK-EP

Страница 2: ...2 YK EP Style B Centrifugal Chiller...

Страница 6: ...6 YK EP Style B Centrifugal Chiller...

Страница 227: ...Figure 72 Sample printout of Status 227 YK EP Style B Centrifugal Chiller...

Страница 228: ...Figure 73 Sample printout of Status cont YK EP Style B Centrifugal Chiller 228...

Страница 229: ...Figure 74 Sample printout of Setpoints 229 YK EP Style B Centrifugal Chiller...

Страница 230: ...Figure 75 Sample printout of Setpoints cont YK EP Style B Centrifugal Chiller 230...

Страница 231: ...Figure 76 Sample printout of Schedule 231 YK EP Style B Centrifugal Chiller...

Страница 232: ...Figure 77 Sample printout of a Sales order YK EP Style B Centrifugal Chiller 232...

Страница 233: ...Figure 78 Sample printout of a Sales order cont 233 YK EP Style B Centrifugal Chiller...

Страница 234: ...Figure 79 Sample printout of History YK EP Style B Centrifugal Chiller 234...

Страница 235: ...Figure 80 Sample printout of History cont 235 YK EP Style B Centrifugal Chiller...

Страница 236: ...Figure 81 Sample printout of a security log report YK EP Style B Centrifugal Chiller 236...

Страница 260: ...Figure 87 Microboard 031 03630 007 Figure 88 Program card 031 03601 002 YK EP Style B Centrifugal Chiller 260...