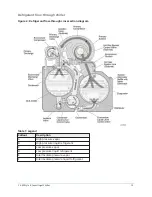

Figure 3: Compressor pre-rotation vanes

When the compressor motor is driven by a YORK Variable Speed Drive, there could be a Variable

Speed Drive (VSD) or a Medium Voltage Variable Speed Drive (MVVSD) applied.

In operation, a liquid (water or brine to be chilled) flows through the cooler, where boiling

refrigerant absorbs heat from the liquid. The chilled liquid is then piped to fan coil units or other air

conditioning terminal units, where it flows through finned coils, absorbing heat from the air. The

warmed liquid is then returned to the chiller to complete the chilled liquid circuit.

The refrigerant vapor, which is produced by the boiling action in the cooler, flows to the

compressor where the rotating impeller increases its pressure and temperature and discharges it

into the condenser. Water flowing through the condenser tubes absorbs heat from the refrigerant

vapor, causing it to condense. The condenser water is supplied to the chiller from an external

source, usually a cooling tower. The condensed refrigerant drains from the condenser into the

liquid return line, where the variable orifice meters the flow of liquid refrigerant to the cooler to

complete the refrigerant circuit.

The major components of a chiller are selected to handle the refrigerant, which would be

evaporated at full load design conditions. However, most systems will be called upon to deliver full

load capacity for only a relatively small part of the time the unit is in operation.

Capacity control

The major components of a chiller are selected for full load capacities, therefore capacity must be

controlled to maintain a constant chilled liquid temperature leaving the cooler. Pre-Rotation Vanes

(PRV), located at the entrance to the compressor impeller, compensate for variation in load (Refer

to Figure 3).

The position of these vanes is automatically controlled through a lever arm attached to an electric

motor located outside the compressor housing. The automatic adjustment of the vane position in

effect provides the performance of many different compressors to match various load conditions

from full load with vanes wide open to minimum load with vanes completely closed.

YK-EP Style B Centrifugal Chiller

12

Содержание YK-EP

Страница 2: ...2 YK EP Style B Centrifugal Chiller...

Страница 6: ...6 YK EP Style B Centrifugal Chiller...

Страница 227: ...Figure 72 Sample printout of Status 227 YK EP Style B Centrifugal Chiller...

Страница 228: ...Figure 73 Sample printout of Status cont YK EP Style B Centrifugal Chiller 228...

Страница 229: ...Figure 74 Sample printout of Setpoints 229 YK EP Style B Centrifugal Chiller...

Страница 230: ...Figure 75 Sample printout of Setpoints cont YK EP Style B Centrifugal Chiller 230...

Страница 231: ...Figure 76 Sample printout of Schedule 231 YK EP Style B Centrifugal Chiller...

Страница 232: ...Figure 77 Sample printout of a Sales order YK EP Style B Centrifugal Chiller 232...

Страница 233: ...Figure 78 Sample printout of a Sales order cont 233 YK EP Style B Centrifugal Chiller...

Страница 234: ...Figure 79 Sample printout of History YK EP Style B Centrifugal Chiller 234...

Страница 235: ...Figure 80 Sample printout of History cont 235 YK EP Style B Centrifugal Chiller...

Страница 236: ...Figure 81 Sample printout of a security log report YK EP Style B Centrifugal Chiller 236...

Страница 260: ...Figure 87 Microboard 031 03630 007 Figure 88 Program card 031 03601 002 YK EP Style B Centrifugal Chiller 260...