Warning – Motor Bearing Lube Suggested

The Operating Hours Since Last Motor Lubrication has exceeded 1000 hours. This will be displayed

until manually cleared by the Operator or the Operating Hours Since Last Motor Lubrication

exceed 1200 hours, whereupon it is replaced by the message WARNING – MOTOR BEARING LUBE

REQUIRED below. The Operator clears this message by entering his/her initials, name or user ID

in OPERATOR access level (or higher) using the MOTOR LUBE ACKNOWLEDGE key on the MOTOR

LUBRICATION Screen. Refer to the

for entry instructions. The date and

time of this entry is automatically logged as the Date Of Last Motor Lubrication and Time Of Last

Motor Lubrication. It also resets the Operating Hours Since Last Lubrication to zero. The date this

warning occurs is stored as the Date Of Last Motor Lubrication Warning Or Fault. This warning

message will not be displayed if the Auto Lube Setpoint on the MOTOR LUBRICATION Screen

enabled.

Warning – Motor Bearing Lube Required

The Operating Hours Since Last Motor Lubrication has exceeded 1200 hours. This replaces

WARNING – MOTOR BEARING LUBE SUGGESTED above. This is displayed until manually cleared by

the Operator or the Operating Hours Since Last Motor Lubrication exceed 1400 hours, whereupon

it is replaced by the message Motor – Lack Of Bearing Lubrication below. The Operator clears this

message by entering his/her initials, name or user ID in OPERATOR access level (or higher) using

the MOTOR LUBE ACKNOWLEDGE key on the MOTOR LUBRICATION Screen. Refer to the

for entry instructions. The date and time of this entry is automatically logged as

the Date Of Last Motor Lubrication and Time Of Last Motor Lubrication. It also resets the Operating

Hours Since Last Lubrication to zero. The date this warning occurs is stored as the Date Of Last

Motor Lubrication Warning Or Fault. This warning message will not be displayed if the Auto Lube

Setpoint on the MOTOR LUBRICATION Screen enabled.

Warning – Motor – High Winding Temperature

This warning occurs when any of the enabled Motor Winding Temperatures exceeds the following:

[High Winding Temperature Shutdown threshold - 18°F] for 3 continuous seconds. This warning

will automatically clear when all winding temperatures decrease below the warning threshold.

The value programmed for the above threshold is displayed as High Winding Temperature

Shutdown on the MOTOR SETPOINTS Screen. It is programmed with the Winding Setup Setpoint

on that screen. This warning not occur when the Winding Temperature Protection Setpoint is

set to Disabled on the MOTOR DETAILS Screen. Also, it will not act on any RTD input registering

as an open RTD or any individual winding temperature sensor that has been disabled with the

Temperature Disable Setpoint on the MOTOR SETPOINTS Screen.

Warning – Motor – High Bearing Temperature

This warning occurs when either of the enabled motor bearing temperatures exceeds the

programmed High Bearing Temperature Warning for 3 continuous seconds. This warning will

automatically clear when all bearing temperatures decrease below the warning threshold. The

value programmed for this threshold is displayed as High Bearing Temperature Warning on the

MOTOR SETPOINTS Screen. It is programmed with the Bearing Setup Setpoint on that screen. This

warning not occur when the Bearing Temperature Protection Setpoint is set to Disabled on the

MOTOR DETAILS Screen. Also, it will not act on any RTD input registering as an open RTD.

Warning – Motor – Bearing Vibration Baseline Not Set

Displayed until both the Shaft End and Opposite Shaft End motor bearing vibration baseline values

are entered on the MOTOR DETAILS Screen. This can be done either manually with the Manual

Baseline Setpoint or automatically with the AUTO BASELINE key on that screen. While this message

is displayed, the vibration baseline values are set to X.X.

195

YK-EP Style B Centrifugal Chiller

Содержание YK-EP

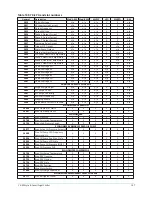

Страница 2: ...2 YK EP Style B Centrifugal Chiller...

Страница 6: ...6 YK EP Style B Centrifugal Chiller...

Страница 227: ...Figure 72 Sample printout of Status 227 YK EP Style B Centrifugal Chiller...

Страница 228: ...Figure 73 Sample printout of Status cont YK EP Style B Centrifugal Chiller 228...

Страница 229: ...Figure 74 Sample printout of Setpoints 229 YK EP Style B Centrifugal Chiller...

Страница 230: ...Figure 75 Sample printout of Setpoints cont YK EP Style B Centrifugal Chiller 230...

Страница 231: ...Figure 76 Sample printout of Schedule 231 YK EP Style B Centrifugal Chiller...

Страница 232: ...Figure 77 Sample printout of a Sales order YK EP Style B Centrifugal Chiller 232...

Страница 233: ...Figure 78 Sample printout of a Sales order cont 233 YK EP Style B Centrifugal Chiller...

Страница 234: ...Figure 79 Sample printout of History YK EP Style B Centrifugal Chiller 234...

Страница 235: ...Figure 80 Sample printout of History cont 235 YK EP Style B Centrifugal Chiller...

Страница 236: ...Figure 81 Sample printout of a security log report YK EP Style B Centrifugal Chiller 236...

Страница 260: ...Figure 87 Microboard 031 03630 007 Figure 88 Program card 031 03601 002 YK EP Style B Centrifugal Chiller 260...