3-24

CHAPTER 3 Installation

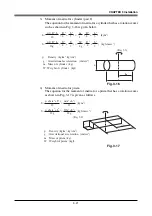

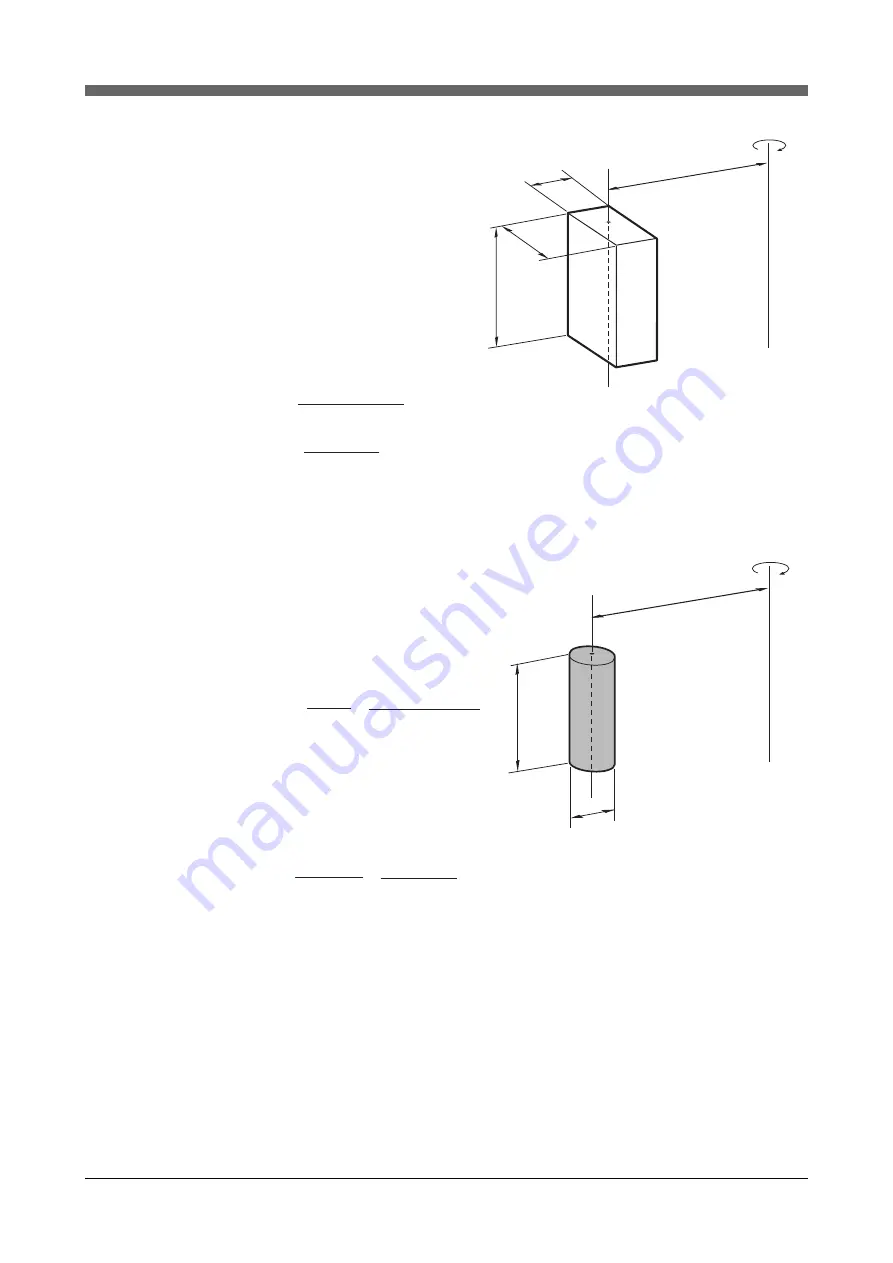

2) Moment of inertia of the chuck

When the chuck form resem-

bles that shown in Fig. 3-23,

the weight of the chuck (Wc)

is

Wc = 0.0078

×

2

×

4

×

6

= 0.37 (kgf)

The moment of inertia of the

chuck (Jc) is then calculated

from Eq. 3-7.

Jc =

0.37

×

(2

2

+4

2

)

12

×

980

0.37

×

10

2

+

980

= 0.038 (kgfcmsec

2

)

Fig. 3-23

10cm

2cm

6cm

4cm

R-axis

3) Moment of inertia of workpiece

When the workpiece form

resembles that shown in Fig.

3-24, the weight of the

workpiece (Ww) is

Ww =

ρπ

D

2

h

=

0.0078

π

×

2

2

×

4

4

4

= 0.098 (kgf)

The moment of inertia of the

workpiece (Jw) is then calcu-

lated from Eq. 3-5.

Jw=

0.097

×

2

2

+

0.097

×

10

2

8

×

980 980

= 0.010 (kgfcmsec

2

)

Fig. 3-24

10cm

4cm

R-axis

2cm

4) Total weight

The total weight (W) is calculated as follows:

W = Ws + Wc + Ww = 0.84 (kgf)

5) Total moment of inertia

The total moment of inertia (J) is then obtained as follows:

J = Js + Jc + Jw = 0.062 (kgfcmsec

2

)

Содержание YK-X Series

Страница 1: ...User s Manual ENGLISH E YAMAHA SCARA ROBOT E35 Ver 1 08 YK XG YK X series ...

Страница 2: ......

Страница 6: ...MEMO ...

Страница 10: ...MEMO ...

Страница 12: ...MEMO ...

Страница 29: ...CHAPTER 2 Functions 1 Robot Manipulator 2 1 2 Robot Controller 2 3 3 Robot initialization number list 2 4 ...

Страница 30: ...MEMO ...

Страница 36: ...MEMO ...

Страница 46: ...3 10 CHAPTER 3 Installation Ground symbol M4 Ground terminal Fig 3 6 Ground terminal ...

Страница 64: ...3 28 CHAPTER 3 Installation Hole diameter Bolt Slot Spline shaft End effector or stay Fig 3 27 ...

Страница 78: ...3 42 MEMO ...

Страница 80: ...MEMO ...

Страница 91: ...4 11 CHAPTER 4 Adjustment X axis origin sensor stay X axis origin sensor Bolt Cover q w Fig 4 3 b ...

Страница 101: ...4 21 CHAPTER 4 Adjustment Cover Elongated hole Y axis origin sensor stay Bolt Fig 4 8 a ...

Страница 102: ...4 22 CHAPTER 4 Adjustment Dog Hex nut Fig 4 8 b Bolt Y axis arm X axis arm Fig 4 8 c ...

Страница 106: ...4 26 CHAPTER 4 Adjustment R axis origin dog Bolt R axis origin sensor stay R axis origin sensor q w Cover Fig 4 9 ...

Страница 119: ...4 39 CHAPTER 4 Adjustment R End effector End effector Z Y X Fig 4 18 ...

Страница 120: ...4 40 MEMO ...

Страница 122: ...MEMO ...

Страница 138: ...5 16 CHAPTER 5 Periodic Inspection M6 16 M5 16 X axis motor Base Fig 5 3 ...

Страница 146: ...5 24 CHAPTER 5 Periodic Inspection M3 16 M4 18 X axis arm Fig 5 10 ...

Страница 155: ...5 33 CHAPTER 5 Periodic Inspection O ring r M5 14 M6 16 R axis motor Fig 5 17 ...

Страница 156: ...5 34 CHAPTER 5 Periodic Inspection M3 14 M3 16 O ring w Fig 5 18 ...

Страница 161: ...CHAPTER 6 Increasing the robot operating speed 1 Increasing the robot operating speed 6 1 ...

Страница 162: ...MEMO ...

Страница 168: ...6 6 MEMO ...

Страница 170: ...MEMO ...

Страница 177: ...MEMO ...