5-27

CHAPTER 5 Periodic Inspection

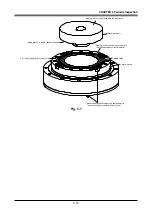

3. R-axis

1) Prepare the following tools and items.

• Harmonic grease 4B No.2

• Waste cloth (rag)

• Phillips screwdriver

• Hex wrench set

• Screw Lock (thread sealant)

• Torque wrench

• Hook wrench

• Replacement parts (See table below.)

Replacement parts

Parts name

Type No.

YAMAHA Parts No.

Note

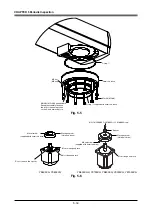

Harmonic drive

Edge seal

SHF-17-30

KBF-M1821-000

Lower part of harmonic drive

O-ring

q

Rubber wire diameter 1.78mm

×

Ring inner diameter 63.22mm

KN4-M1896-000

w

Rubber wire diameter 0.80mm

×

Ring inner diameter 45.40mm

V-25A (N+C)

KN3-M257L-000

KBF-M1886-000

Supplied with harmonic drive

e

Rubber wire diameter 1.00mm

×

Ring inner diameter 35.3mm

90990-17J031

Spline nut

r

Rubber wire diameter 1.00mm

×

Ring inner diameter 46.00mm

90990-17J032

Y-axis arm

t

Rubber wire diameter 0.60mm

×

Ring inner diameter 22.00mm

90990-17J033

Wave generator

FORSHEDA

YK500XG, YK600XG

Replacement parts

Parts name

Type No.

YAMAHA Parts No.

Note

Harmonic drive

Edge seal

SHF-20-50

KBP-M1821-000

Lower part of harmonic drive

O-ring

q

S71(JIS)

KN3-M2159-000

w

Rubber wire diameter 0.99mm

×

Ring inner diameter 53.28mm

V-28A (N+C)

KN3-M2144-000

KBP-M1886-000

Supplied with harmonic drive

e

Rubber wire diameter 1.00mm

×

Ring inner diameter 43.00mm

90990-17J036

Spline nut

r

Rubber wire diameter 1.30mm

×

Ring inner diameter 53.00mm

90990-17J038

Y-axis arm

t

Rubber wire diameter 0.5mm

×

Ring inner diameter 28.00mm

90990-17J037

Wave generator

FORSHEDA

YK600XGH, YK700XG, YK800XG, YK900XG, YK1000XG

2) Turn off the controller.

3) Place a sign indicating that the robot is being inspected, to keep others from

operating the controller switch.

4) Enter the safeguard enclosure.

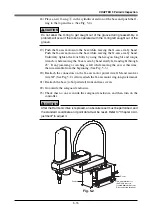

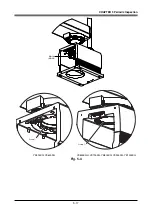

5) Remove the cover. (See Fig. 5-13.)

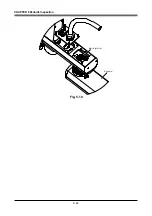

Unplug the connectors on the R-axis motor power wire RM and resolver

wire RP in the Y-axis arm. Also disconnect the R-axis motor ring-tongue

terminal.

WARNING

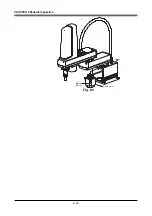

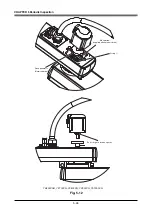

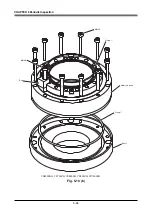

The Z-axis will slide down when the bearing mounting bolts are removed in the

next step, causing a hazardous situation. Prop the Z-axis with a support stand

before loosening these bolts. (See Fig. 5-14.)

Содержание YK-X Series

Страница 1: ...User s Manual ENGLISH E YAMAHA SCARA ROBOT E35 Ver 1 08 YK XG YK X series ...

Страница 2: ......

Страница 6: ...MEMO ...

Страница 10: ...MEMO ...

Страница 12: ...MEMO ...

Страница 29: ...CHAPTER 2 Functions 1 Robot Manipulator 2 1 2 Robot Controller 2 3 3 Robot initialization number list 2 4 ...

Страница 30: ...MEMO ...

Страница 36: ...MEMO ...

Страница 46: ...3 10 CHAPTER 3 Installation Ground symbol M4 Ground terminal Fig 3 6 Ground terminal ...

Страница 64: ...3 28 CHAPTER 3 Installation Hole diameter Bolt Slot Spline shaft End effector or stay Fig 3 27 ...

Страница 78: ...3 42 MEMO ...

Страница 80: ...MEMO ...

Страница 91: ...4 11 CHAPTER 4 Adjustment X axis origin sensor stay X axis origin sensor Bolt Cover q w Fig 4 3 b ...

Страница 101: ...4 21 CHAPTER 4 Adjustment Cover Elongated hole Y axis origin sensor stay Bolt Fig 4 8 a ...

Страница 102: ...4 22 CHAPTER 4 Adjustment Dog Hex nut Fig 4 8 b Bolt Y axis arm X axis arm Fig 4 8 c ...

Страница 106: ...4 26 CHAPTER 4 Adjustment R axis origin dog Bolt R axis origin sensor stay R axis origin sensor q w Cover Fig 4 9 ...

Страница 119: ...4 39 CHAPTER 4 Adjustment R End effector End effector Z Y X Fig 4 18 ...

Страница 120: ...4 40 MEMO ...

Страница 122: ...MEMO ...

Страница 138: ...5 16 CHAPTER 5 Periodic Inspection M6 16 M5 16 X axis motor Base Fig 5 3 ...

Страница 146: ...5 24 CHAPTER 5 Periodic Inspection M3 16 M4 18 X axis arm Fig 5 10 ...

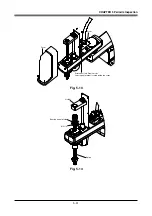

Страница 155: ...5 33 CHAPTER 5 Periodic Inspection O ring r M5 14 M6 16 R axis motor Fig 5 17 ...

Страница 156: ...5 34 CHAPTER 5 Periodic Inspection M3 14 M3 16 O ring w Fig 5 18 ...

Страница 161: ...CHAPTER 6 Increasing the robot operating speed 1 Increasing the robot operating speed 6 1 ...

Страница 162: ...MEMO ...

Страница 168: ...6 6 MEMO ...

Страница 170: ...MEMO ...

Страница 177: ...MEMO ...