Operation

Turb PLUS 2000

100193 Rev 0 ba77254e01 11/2020

53

Certain routine maintenance items, such as calibration and desiccant change,

are triggered by internal diagnostic alerts. The time to take other routine

maintenance tasks, such as removal of flow through to manually clean

cuvette, will vary based on system usage and water quality conditions.

Cleaning the Flow-Through Cuvette

Measurement cuvettes used for both the grab sample and the flow through should be clean and

free of marks or scratches. It is recommended to check, and if required clean, the cuvette every

three months when performing the primary calibration. The flow-through assembly must be

removed to perform the calibration procedure.

Cleaning is accomplished by cleaning the interior and exterior with a detergent solution and then

rinsing several times with distilled or de-ionized water.

The cuvette can be replaced by first shutting off the flow using the provided shutoff clamp;

unscrewing the old cuvette and replacing with a fresh clean one.

Replacing the Source Lamp

The source lamps in the Turb PLUS 2000 instruments are designed for long life. The IR lamp and

white light version have long lives. These lamps, however, are not covered by the warranty. If the

lamp should need replacement, we recommend calling Xylem Analytics Germany for assistance.

Optional Factory Installed 24V Option

This factory installed option allows for the operation of the Turb PLUS 2000 from 24 volts DC. For

this instrument, the changes are in the junction box only.

The range of correct operation is from 18-36VDC. Caution must be used to not exceed this

voltage.

Connections are not polarity sensitive and are made to the same place as mentioned in section

3.4.1.

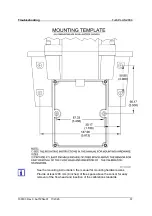

Figure 11: Flow-Through Assembly

Содержание 600026

Страница 1: ...OPERATING MANUAL 100193 Rev 0 ba77254e01 11 2020 Turb PLUS 2000 PROCESS TURBIDIMETER...

Страница 2: ...Turb PLUS 2000 2 100193 Rev 0 ba77254e01 11 2020 Copyright 2020 Xylem Analytics Germany GmbH...

Страница 58: ......

Страница 59: ......