Owner Service

15

MAN1279 (15/04/2019)

OWNER SERVICE

The information in this section is written for operators who possess basic

mechanical skills. If you need help, your dealer has trained service technicians

available. For your protection, read and follow the safety information in this

manual.

■

Keep all persons away from operator control area while performing

adjustments, service, or maintenance.

■

Before working underneath, disconnect driveline from tractor, lower

wings to the ground, raise cutter, and engage transport lock-up in the

locked position. Attach parking jack and lower to the ground. Securely

block all four corners of the centre section and each wing with jack-

stands. Blocking up prevents the cutter from dropping due to hydraulic

leak down, hydraulic system failure, or mechanical component failure.

■

Service and maintenance work not covered in OWNER SERVICE

must be done by a qualified dealership. Special skills, tools, and safety

procedures may be required. Failure to follow these instructions can

result in serious injury or death.

■

Before servicing, adjusting, repairing or unplugging, stop tractor

engine, place all controls in neutral, set park brake, remove ignition key,

and wait for all moving parts to stop.

■

Never perform service, cleaning, or maintenance with engine run-

ning.

■

If you do not understand any part of this manual and need assis-

tance, see your dealer.

■

Always wear relatively tight and belted clothing to avoid entangle-

ment in moving parts. Wear sturdy, rough-soled work shoes and protec-

tive equipment for eyes, hair, hands, hearing, and head; and respirator or

filter mask where appropriate.

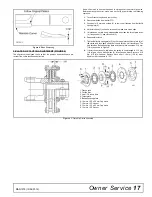

BLOCKING METHOD

To minimize the potential hazards of working underneath the cutter, follow

these procedures:

■

Before performing any service or maintenance, lower equipment to

ground or block securely, turn off engine, remove key, and disconnect

driveline from tractor PTO.

■

Never go underneath equipment (lowered to the ground or raised)

unless it is properly blocked and secured. Never place any part of the

body underneath equipment or between moveable parts even when the

engine has been turned off. Hydraulic system leak down, hydraulic sys-

tem failures, mechanical failures, or movement of control levers can

cause equipment to drop or rotate unexpectedly and cause severe injury

or death. Follow Operator's Manual instructions for working underneath

and blocking requirements or have work done by a qualified dealer.

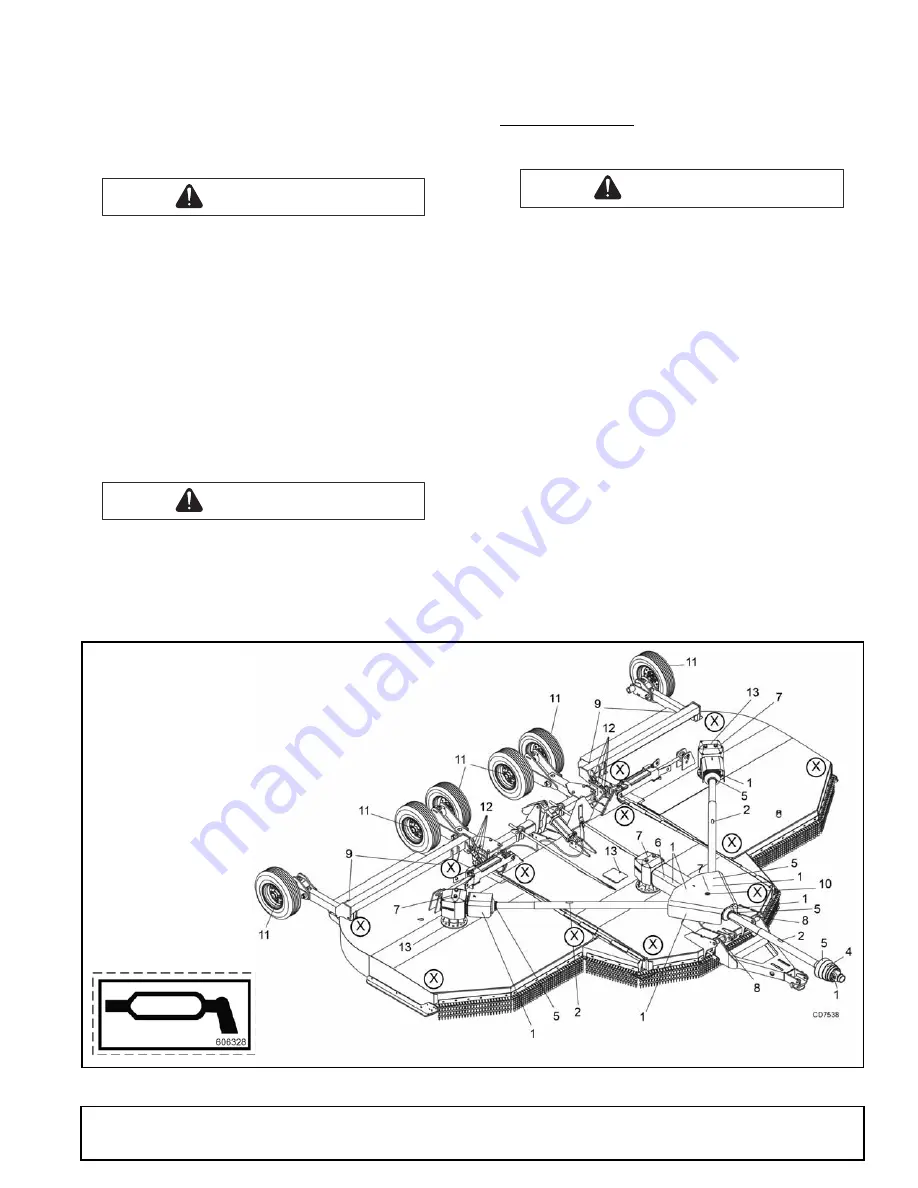

Do not position jackstands under wheels, axles, or wheel supports. Compo-

nents can rotate and cause cutter to fall.

1.

Jackstands with a load rating of 453.6 kg (1000 lbs.) or more are the only

approved blocking device for this cutter. Install jackstands (shown by

X

s

in Figure 6) under the cutter before working underneath unit.

2.

Consider the overall stability of the blocked unit. Just placing jackstands

underneath will not ensure your safety.

The working surface must be level and solid to support the weight on the

jackstands. Make sure jackstands are stable, both top and bottom. Make

sure cutter is approximately level.

3.

With full cutter weight lowered onto jackstands, test blocking stability

before working underneath.

4.

If cutter is attached to tractor when blocking, set the brakes, remove key,

and block cutter before working underneath.

5.

Securely block rear tractor wheels, in front and behind. Tighten tractor

lower 3-point arm anti-sway mechanism to prevent side-to-side

movement.

Figure 6

. Jackstand Placement and Lubrication Points

WARNING

WARNING

CAUTION

CAUTION

WARNING

WARNING

1. Driveline U-joint

10 Hours

2. Telescoping shaft

10 Hours

4. CV body assembly

10 hours

(10 pumps minimum)

5. Driveline shield

10 Hours

6. Splined yoke

10 Hours

7. Gearbox (above lower

Daily

line on dipstick)

8. Tongue pivot

40 Hours

9. Wheel yoke pivot

40 Hours

10. Gearbox (bottom of

Daily

side hole)

11. Tailwheel spindle

20 Hours

12. Turnbuckle

40 Hours

13. Blade Pin

40 Hours

Содержание BATWING BW20.50QE

Страница 1: ...OPERATOR S MANUAL BATWING ROTARY CUTTER Rev 22 10 2019 BW20 50QE BW20 60QE BW20 70QE MAN1279...

Страница 10: ...10 Declaration of Conformity MAN1279 15 04 2019...

Страница 45: ...Common Components 45 MAN1279 15 04 2019 NOTES...

Страница 46: ...46 50 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 50QE...

Страница 50: ...50 50 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 50QE...

Страница 55: ...50 Series Parts 55 MAN1279 15 04 2019 NOTES...

Страница 56: ...56 60 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 60QE...

Страница 60: ...60 60 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 60QE...

Страница 66: ...66 70 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 70QE...

Страница 70: ...70 70 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 70QE...

Страница 81: ...MANUEL DE L UTILISATEUR BATWING FAUCHEUSE ROTATIVE R v 15 04 2019 BW20 50QE BW20 60QE BW20 70QE MAN1279...

Страница 90: ...10 Declaration of Conformity MAN1279 15 04 2019 10 D claration de conformit MAN1279 15 04 2019...