12

Operation

MAN1279 (15/04/2019)

Cutting Height Adjustment

NOTICE

■

Avoid ground contact with blades. Striking ground with blades pro-

duces one of the most damaging shock loads a cutter can encounter. If

this occurs repeatedly, the cutter, driveline, and gearboxes will be dam-

aged.

Cutting height range is from 50 mm (2 in.) to 381 mm (15 in). A hydraulic cylin-

der is used for cutting height adjustment.

When selecting a cutting height, you should consider the area of operation. If

the ground is rolling and has mounds the blades could contact, set the cutting

height accordingly. The cutting height (blade edge) is approximately 25.4 mm

(1 in.) above the bottom of the side skid.

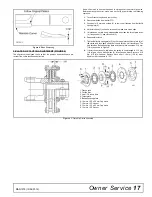

Cutting Height (Normal Mowing) - Centre Section

1.

Position the cutter on a hard level surface and select an approximate

cutting height, for example 152.4 mm (6 in.).

2.

Raise wings and lock them in the UP position.

3.

Use the hydraulic cylinder to raise or lower the centre section to obtain a

distance of 127 mm (5 in.) from bottom edge of skid shoe to the ground.

4.

Place jackstands under the four corners of the centre section. See

illustration on page 15. Lower centre section to relieve pressure on

attitude rod nuts.

5.

Loosen outer jam nut on the attitude rods.

6.

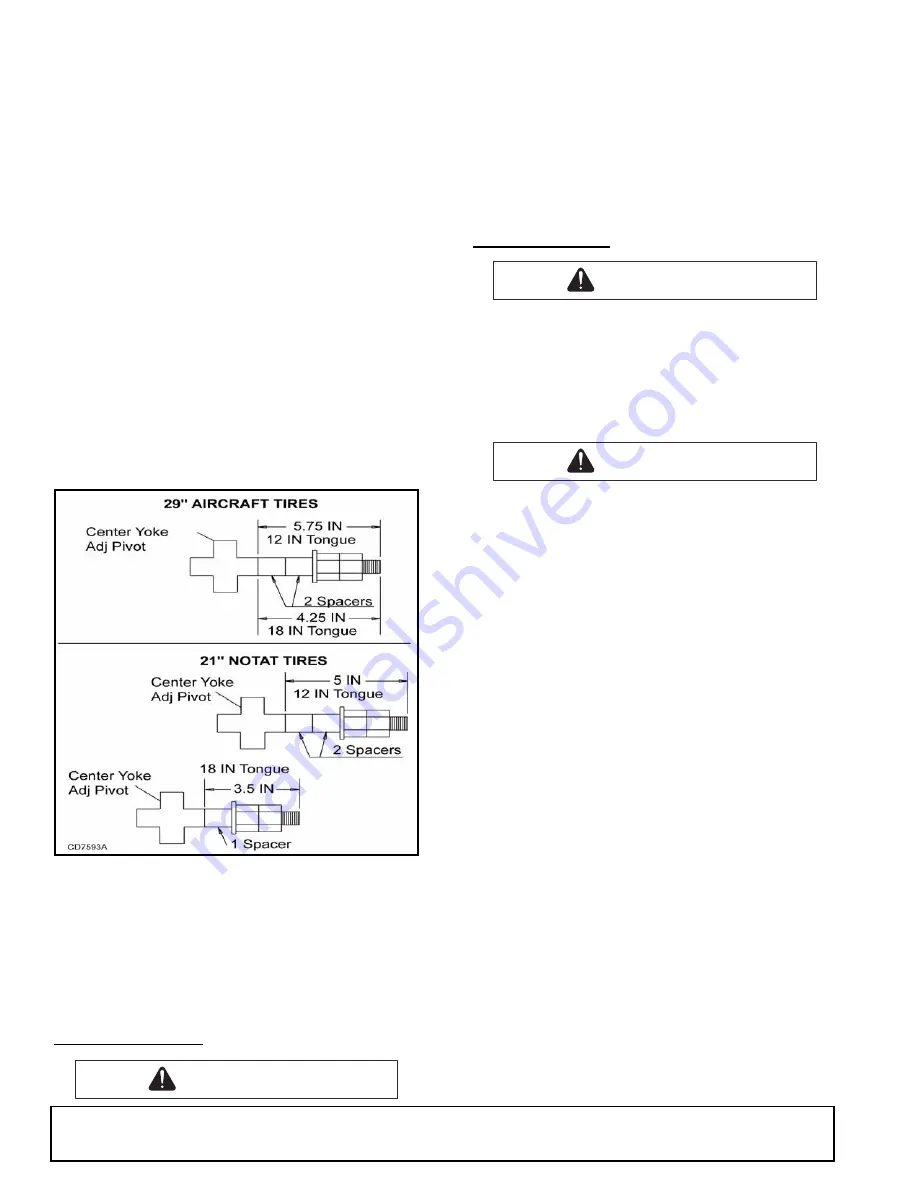

Adjust inner nuts in or out until the rear of the cutter is approximately 12.7

mm (1/2 in.) higher than the front. See Figure 1A. It’s used as a starting

point for adjusting the attitude rod, based on different tongue height and

wheel options.

7.

Raise cutter, remove jackstands and check deck height. Tighten jam nuts

against sleeve.

Figure 1A

. Attitude Rod Adjustment

Cutting Height (Normal Mowing) - Wings

1.

Lower wings to normal mowing position.

2.

Loosen the jam nut on the adjustable link (turn buckle).

3.

Lengthening the link will raise the wing, shortening the link will lower the

wing. The rear edge of the wing should be parallel to the ground.

4.

Make sure jam nuts are tightened once wing is leveled.

When using the cutter to shred, the rear of the cutter deck should be approxi-

mately 12.7 mm to 25.4 mm (1/2 in. to 1 in.) lower than the front.

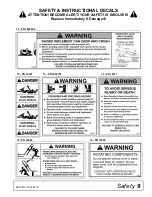

TRACTOR OPERATION

■

Power unit must be equipped with Roll Over Protection System

(ROPS) or ROPS cab and seat belt. Keep seat belt securely fastened. Fall-

ing off power unit can result in death from being run over or crushed.

Keep foldable ROPS system in “locked up” position at all times.

Use care when operating around tree limbs and other low objects. Avoid being

knocked off tractor and being injured.

The cutter is operated with tractor controls. Engage the PTO at a low rpm to

prevent excessive loads on the cutter drive system. Increase throttle to recom-

mended PTO operating RPM.

Be sure operator is familiar with all controls and can stop tractor and cutter

quickly in an emergency. The operator should give complete, undivided atten-

tion to operating tractor and cutter.

CUTTER OPERATION

■

Look down and to the rear and make sure area is clear before oper-

ating in reverse.

■

Do not operate or transport on steep slopes.

■

Do not stop, start, or change directions suddenly on slopes.

■

Use extreme care and reduce ground speed on slopes and rough

terrain.

■

Watch for hidden hazards on the terrain during operation.

■

Stop power unit and equipment immediately upon striking an

obstruction. Turn off engine, remove key, inspect, and repair any damage

before resuming operation.

When beginning operation of the cutter, make sure that all persons are in a

safe location.

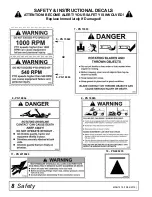

Power for operating the cutter is supplied by the tractor PTO. Operate PTO at

1000 RPM for Q models.

Know how to stop the tractor and cutter quickly in an emergency.

To stop cutter when operating under normal conditions, reduce tractor RPM to

idle and disengage PTO to reduce freewheeling on cutting elements.

Engage PTO at a low engine rpm to minimize stress on the drive system and

gearbox.

With PTO engaged, raise PTO speed to 1000 RPM and maintain throughout

cutting operation.

Gearbox protection is provided by a slip clutch with replacement fiber disc. The

slip clutch is designed to slip when excessive torsional loads occur.

Move slowly into material. Adjust tractor ground speed to provide a clean cut

without lugging the tractor engine.

Use a slow ground speed for better shredding.

Proper ground speed will depend on the terrain and the material’s height, type,

and density.

Normally, ground speed will range from 3 to 8 km/h (2 to 5 mph). Tall, dense

material should be cut at a low speed; thin, medium-height material can be cut

at a faster ground speed.

Always operate tractor PTO at 1000 RPM to maintain blade speed and to pro-

duce a clean cut.

Under certain conditions tractor tires may roll down some grass and prevent

cutting at the same height as the surrounding area. When this occurs, reduce

your ground speed but maintain PTO at 1000 RPM. The lower ground speed

will permit grass to rebound partially.

Mowing Tips

Maximum recommended ground speed for cutting or shredding is 10 km/h (6

mph). Adjust tractor ground speed by using higher or lower gears to provide a

clean cut without lugging tractor engine.

Tall material should be cut twice. Cut material higher the first pass. Cut at

desired height at 90 degrees the second pass.

Remember, sharp blades produce cleaner cuts and use less power.

Before entering an area, analyze it to determine the best procedure. Consider

the height and type of material to be cut and the terrain type (hilly, level or

rough, etc.).

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

Содержание BATWING BW20.50QE

Страница 1: ...OPERATOR S MANUAL BATWING ROTARY CUTTER Rev 22 10 2019 BW20 50QE BW20 60QE BW20 70QE MAN1279...

Страница 10: ...10 Declaration of Conformity MAN1279 15 04 2019...

Страница 45: ...Common Components 45 MAN1279 15 04 2019 NOTES...

Страница 46: ...46 50 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 50QE...

Страница 50: ...50 50 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 50QE...

Страница 55: ...50 Series Parts 55 MAN1279 15 04 2019 NOTES...

Страница 56: ...56 60 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 60QE...

Страница 60: ...60 60 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 60QE...

Страница 66: ...66 70 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 70QE...

Страница 70: ...70 70 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 70QE...

Страница 81: ...MANUEL DE L UTILISATEUR BATWING FAUCHEUSE ROTATIVE R v 15 04 2019 BW20 50QE BW20 60QE BW20 70QE MAN1279...

Страница 90: ...10 Declaration of Conformity MAN1279 15 04 2019 10 D claration de conformit MAN1279 15 04 2019...