Dealer Service

27

MAN1279 (15/04/2019)

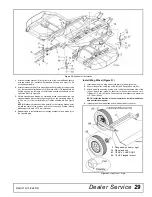

ASSEMBLY INSTRUCTIONS

DEALER SET-UP INSTRUCTIONS

Assembly of this cutter is the responsibility of the WOODS dealer. It should be

delivered to the owner completely assembled, lubricated and adjusted for nor-

mal cutting conditions.

The cutter is shipped partially assembled. Assembly will be easier if compo-

nents are aligned and loosely assembled before tightening hardware. Recom-

mended torque values for hardware are located on page 76.

Select a suitable working area. A smooth hard surface, such as concrete, will

make assembly much quicker. Open parts boxes and lay out parts and hard-

ware to make location easy. Refer to illustrations, accompanying text, parts lists

and exploded view drawings.

Complete the check list on page 30 when assembly is complete and cutter is

delivered to the customer.

■

Before working underneath, carefully read Operator’s Manual

instructions, disconnect driveline, raise mower, securely block up all cor-

ners with jackstands, and check stability. Secure blocking prevents

equipment from dropping due to hydraulic leak down, hydraulic system

failures, or mechanical component failures.

■

Do not disconnect hydraulic lines until machine is securely blocked

or placed in lowest position and system pressure is released by operat-

ing valve levers.

■

Always wear relatively tight and belted clothing to avoid entangle-

ment in moving parts. Wear sturdy, rough-soled work shoes and protec-

tive equipment for eyes, hair, hands, hearing, and head; and respirator or

filter mask where appropriate.

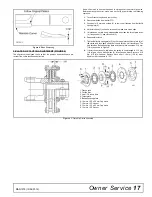

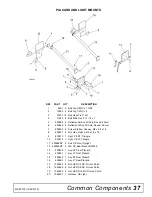

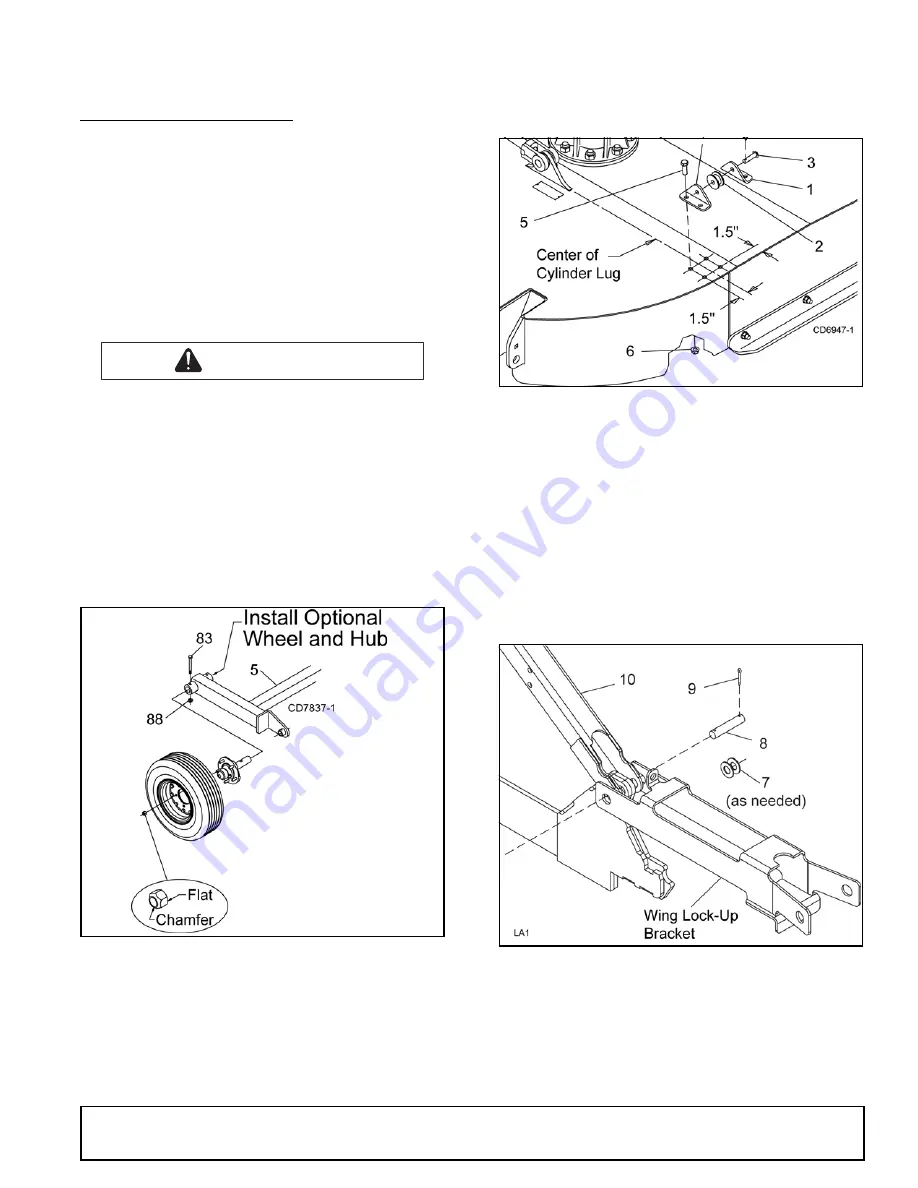

Install Wheel

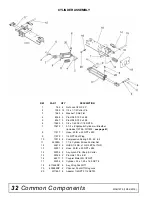

Figure 24

. Center Section Wheel and

Hub Installation

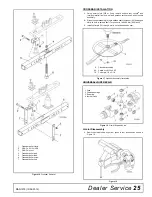

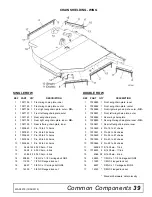

Winch Kit Installation

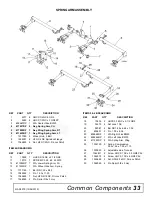

Figure 25

. Roller Assembly Installation

1.

Locate and drill one 14.28 mm (9/16 in.) hole in each wing using

dimensions shown in Figure 25. Assemble items 1, 2, 3 and 4. Use

assembly to locate and drill remaining holes.

2.

Secure idler brackets (1) and rollers (2) to deck with bolts (5) and nuts

(6).

3.

Remove cylinder pin: Place channel (10) over cylinder and cylinder lug.

Place wing lock-up bracket over channel and insert pin (8), washers (7),

and cotter pins (9). NOTE: Washers (7) are used as spacers and are

placed between lock-up bracket and channel (10) as needed.

4.

Repeat step to install second channel (10) on opposite wing.

5.

Attach winch assembly to channels (10) using bolts (5) and lock nuts (6).

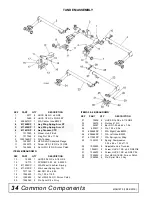

6.

Move SMV sign and hardware to channel as shown in the winch kit

instructions.

7.

Tighten all hardware. See Parts page 77 for complete diagram and part

list.

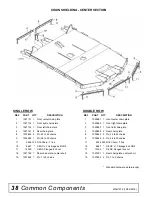

Figure 26

. Winch Channel Installation

WARNING

WARNING

1. Center Wheel Yoke Arm

83. 1/2" NC x 3" HHCS GR5

88. 1/2" NC Flange Lock Nut

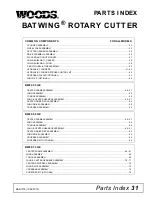

Содержание BATWING BW20.50QE

Страница 1: ...OPERATOR S MANUAL BATWING ROTARY CUTTER Rev 22 10 2019 BW20 50QE BW20 60QE BW20 70QE MAN1279...

Страница 10: ...10 Declaration of Conformity MAN1279 15 04 2019...

Страница 45: ...Common Components 45 MAN1279 15 04 2019 NOTES...

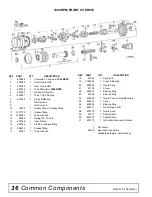

Страница 46: ...46 50 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 50QE...

Страница 50: ...50 50 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 50QE...

Страница 55: ...50 Series Parts 55 MAN1279 15 04 2019 NOTES...

Страница 56: ...56 60 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 60QE...

Страница 60: ...60 60 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 60QE...

Страница 66: ...66 70 Series Parts MAN1279 15 04 2019 CENTER FRAME ASSEMBLY BW20 70QE...

Страница 70: ...70 70 Series Parts MAN1279 15 04 2019 WING CENTER GEARBOX ASSEMBLY BW20 70QE...

Страница 81: ...MANUEL DE L UTILISATEUR BATWING FAUCHEUSE ROTATIVE R v 15 04 2019 BW20 50QE BW20 60QE BW20 70QE MAN1279...

Страница 90: ...10 Declaration of Conformity MAN1279 15 04 2019 10 D claration de conformit MAN1279 15 04 2019...