63899-002 Rev. A 3/20/2024

38

easily be added into the system. The LMV3 compatible part number for purchase is

1000185-KIT

. For

wiring a UV scanner into the control, please reference the LMV3 Technical Instructions link and QR

code found on Page 39. It is important to note that the sight glass must be removed when the UV kit is

installed. There will be no flame signal detected if the glass remains in place.

D: TROUBLESHOOTING

The most common fault codes have been noted below. For all LMV3 fault codes and diagnostic codes please

refer to the LMV3 Technical Instructions below on page 39. A QR code and a URL link have been provided for

a full electronic copy on Page 39.

TABLE 4: COMMON FAULT CODES

Error

Code

(Loc:c:)

Diagnostic

Code

(Loc:d:)

Meaning

Corrective Action

2

Any #

No flame at end

of safety time

A flame failure occurred during lighting.

1. Check the wiring of the ignition transformer, pilot valve, and main valve(s).

2. Check manual shutoff valves for supply gas.

3. Check the position of the air damper and close it further if necessary.

4. Check the flame detector signal in the presence of a known flame source.

Replace the flame detector if it does not produce the anticipated signal.

3

0

Air Pressure Off

The air pressure switch input was de-energized when it should have been energized.

Make sure the blower starts in phase 22 and the switch setpoint is set appropriately.

1

Air Pressure On

The air pressure switch input was energized when it should have been deenergized.

Make sure the blower turns off in phase 78 and the switch setpoint is set appropriately.

If necessary, increase the setting of parameter 213.

4

Air Pressure On

Prevention of

Startup

The air pressure switch input is energized, preventing the LMV3 from starting up.

7

Any #

Loss of flame

1. Increase the setting of parameter 186:01 (fuel 0) or 187:01 (fuel 1). This increases

the FFRT. A maximum setting of 30 equals a 4 second FFRT.

2. Check the flame detector signal in the presence of a known flame source. Replace

the flame detector if it does not produce the anticipated signal.

20

Any #

Gas Pressure

Switch (Min)

1. A fault occurred related to the low gas pressure switch. See diagnostic codes for

more information.

2. The low gas pressure switch (input X5-01.2) opened, causing a fault. Check gas

supply and open any manual shutoff valves. Check the setpoint and wiring of the low

gas pressure switch.

3. The low gas pressure switch was not made by the end of phase 22, preventing the

startup of the LMV3. See diagnostic code 0 for more corrective actions.

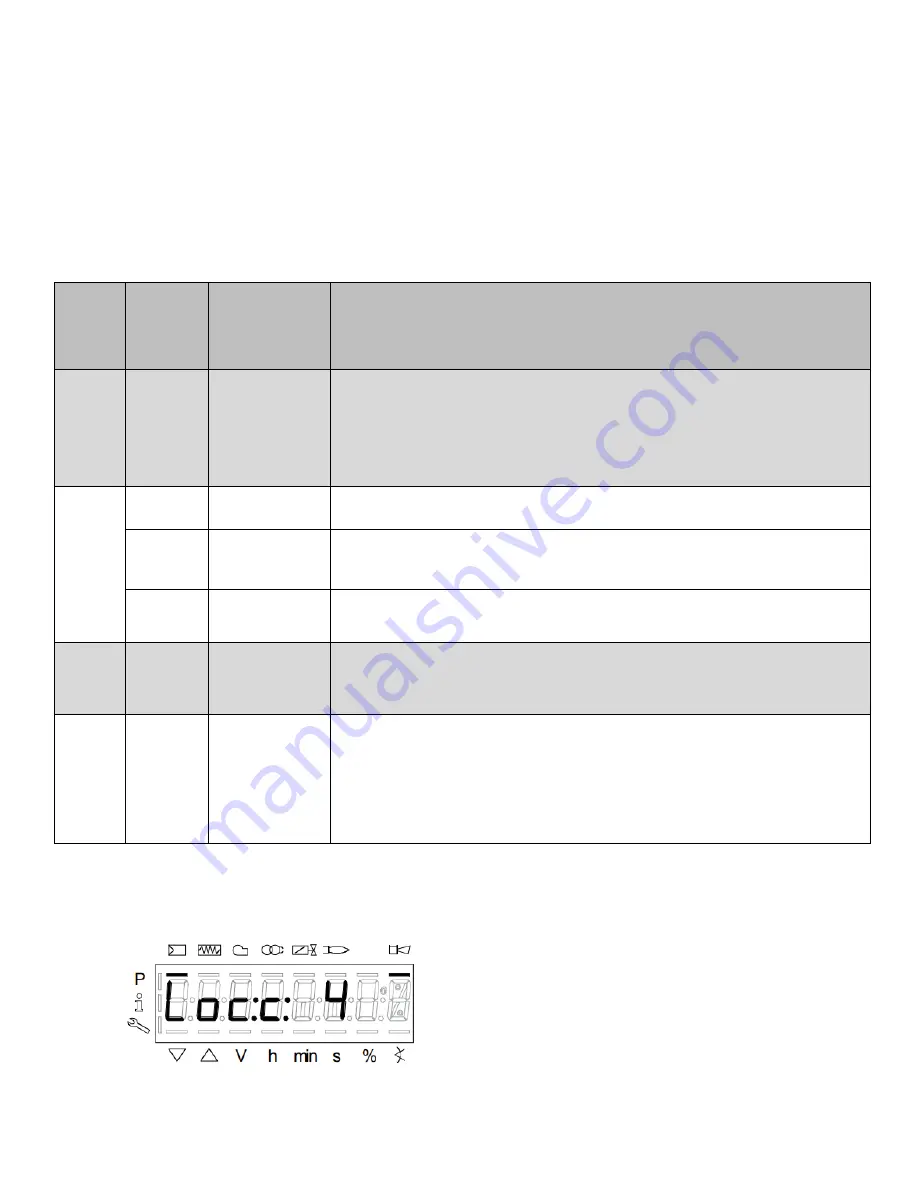

D.1 DISPLAY OF FAULTS

The example shown below displays error code 4, diagnostic 3. Refer to the LMV Manual for a

comprehensive list of fault codes.

Loc:c:

This display shows the current

fault status.

Содержание LC2300M

Страница 35: ...63899 002 Rev A 3 20 2024 35 B WIRING DIAGRAM...

Страница 36: ...63899 002 Rev A 3 20 2024 36...

Страница 57: ...63899 002 Rev A 3 20 2024 57...

Страница 58: ...63899 002 Rev A 3 20 2024 58...

Страница 59: ...63899 002 Rev A 3 20 2024 59...

Страница 60: ...63899 002 Rev A 3 20 2024 60...

Страница 63: ...63899 002 Rev A 3 20 2024 63 This page intentionally left blank...

Страница 64: ...63899 002 Rev A 3 20 2024 64 NOTES...