20 Chapter 3 Installation

SmartCabinet Series Solution Product for IDC or Computer Rooms User Manual

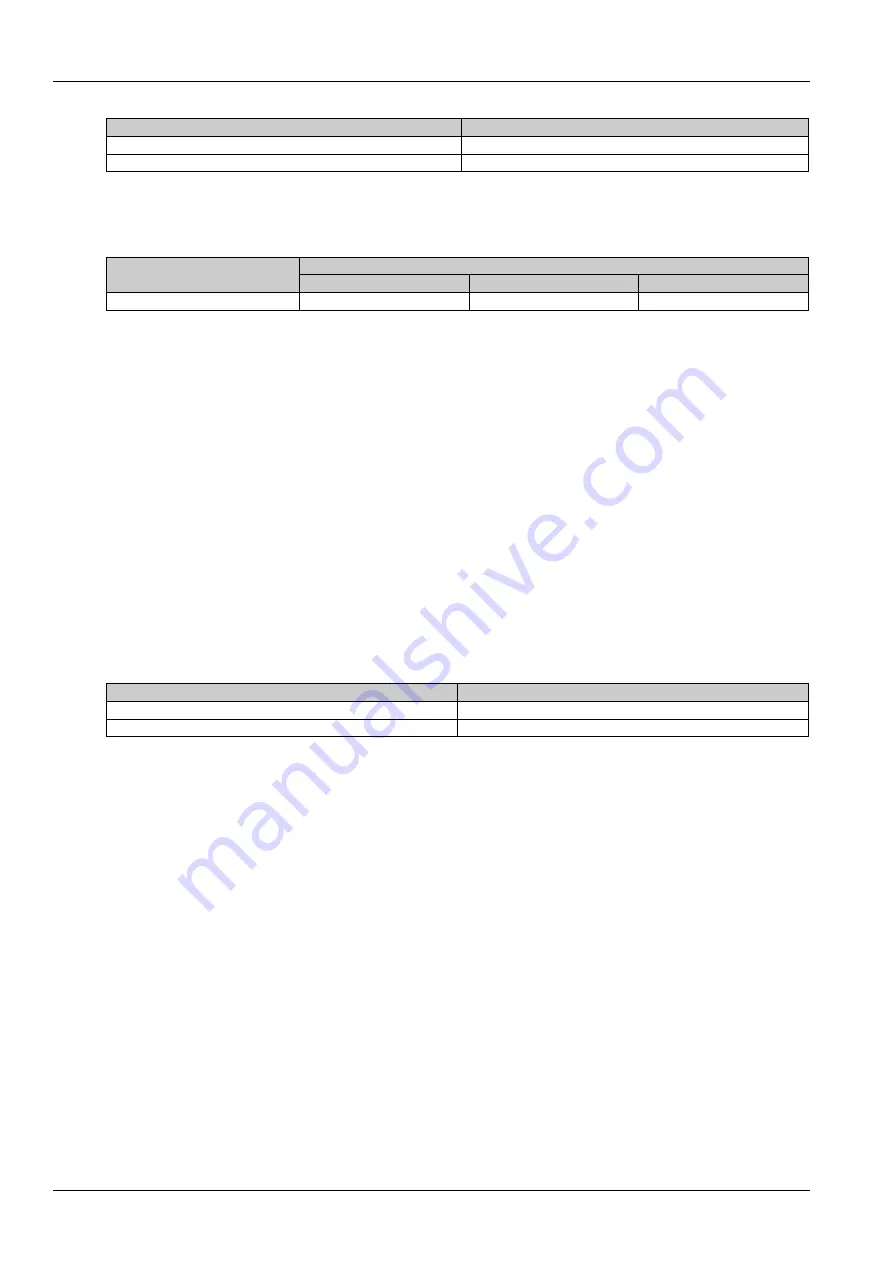

Table 3-1 Vertical distance between indoor unit and outdoor unit

Relative position

Value

Outdoor unit installed higher than indoor unit

Maximum: 15m

Outdoor unit installed lower than indoor unit

Maximum: 5m

5) The equivalent length of each part is given in Table 3-2. The resistance loss caused by elbows and valves has

been taken into consideration. The installer should confirm if these values are appropriate for site conditions.

Table 3-2 Equivalent length of each part

Liquid pipe OD (inch)

Equivalent length (m)

90° elbow

45° elbow

T-type three way

3/8 (More than 10m)

0.21

0.10

0.76

2. Installation notes of connector

Top piping and bottom piping are both OK for the AC of the SmartCabinet system (For bottom piping, loosen the

connectors that connect the pre-installed pipes in the cabinet and the indoor unit). The connectors of the unit are

located on the AC indoor unit and outdoor unit and on top of the cabinet. Be careful when connecting the quick thread

connector. Read through the following steps before making connection.

1) Remove the dust-proof caps.

2) Carefully wipe coupling seats and threaded surface with a clean cloth.

3) Lubricate the male thread with refrigerant oil.

4) Thread the coupling halves together by hand to ensure that the threads mate properly.

5)

Tighten the coupling body’s hexagon nut and union valve until a definite resistance is felt.

6) Use a marking pen to draw a line lengthwise from the coupling union nut to the bulkhead. Tighten the nuts an

additional quarter turn with two wrenches. The misalignment of the lines shows how much the coupling has been

tightened. Two wrenches must be used to cooperate with each other during connection, because one wrench can

damage the coupling copper lines easily.

The recommended torque values are listed in Table 3-3.

Table 3-3 Recommended torque value

Coupling size

Torque value (N.m)

1/4

”

6 ~ 7

1/2

”

8 ~ 9

3. Required Pipe Connections

Refrigerant pipe between the indoor unit and the outdoor unit (discharge pipe and liquid pipe)

1) The copper pipes provided by the factory are 5m. If longer pipes are required, contact Vertiv or your sale agency.

2) The liquid pipe is the refrigerant liquid pipe of the outdoor unit outlet. So a reasonable pipe diameter and length

should be selected for the liquid pipe to ensure that the pressure drop of the refrigerant liquid through the pipe during

unit operation does not exceed 40kPa (5psi ~ 6psi).

3) The pipe should be installed and removed with care so that they will not get kinked or damaged. Use tube benders

and make all bends before making connections to either end.

4) If jointing mode is needed, all refrigerant piping should be connected with silver-brazed joints.

5) Check piping supports, leakage testing, dehydration of refrigerant pipes and evacuation(when the absolute

pressure is about 3-4Kpa , stop evacuation, about 20-30 minituts later ,if the pressure does not rise, then evacuation

finish ,the refrigerant can be added into AC) before using. Use vibration isolating support to isolate the refrigeration

pipes from the building.

6) Use a soft and flexible material to pack around the pipes to protect them from damage caused by going through

openings in walls and to reduce vibration transmission.

7) When the outdoor unit is higher than the indoor unit by 7.5m, an oil trap (oil collector) should be installed at the gas

pipe side. The oil trap can store some frozen oil when the compressor stops. When the compressor starts up, the oil

stored in the oil trap will be sucked into the compressor.

Pipe connection port location