Appendix

0020261188_00 ecoTEC plus Installation and maintenance instructions

51

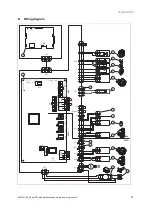

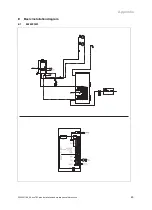

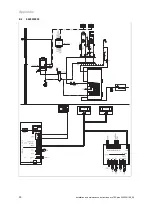

E.3

Key for the basic system diagrams

Component

Meaning

1

Heat generator

3

Heat generator circulation pump

3c

Cylinder charging pump

3e

Circulation pump

3f

Heating pump

5

Monovalent domestic hot water cylinder

8a

Expansion relief valve

8b

Potable water expansion relief valve

8c

Safety group

–

drinking water connection

8e

Heating diaphragm expansion vessel

8f

Diaphragm expansion vessel

–

potable water

9a

Single-room temperature control valve (thermostatic/motorised)

9c

Flow regulator valve

9e

Domestic hot water generation prioritising diverter valve

9h

Filling/draining cock

9j

Tamper-proof capped valve

9k

3-port mixing valve

10c

Non-return valve

10e

Line strainer with magnetite separator

10h

Low loss header

12

System control

12a

Remote control unit

12d

Expansion/wiring centre

12k

Limit thermostat

12m

Outdoor temperature sensor

DHW

Cylinder temperature sensor

FS2

Heating circuit volume temperature sensor

SysFlow

System temperature sensor

Components that have been used multiple times (x) are numbered consecutively (x1, x2, ..., xn).

F

Inspection and maintenance work

–

Overview

The table below lists the manufacturer requirements with respect to minimum inspection and maintenance intervals. If na-

tional regulations and directives require shorter inspection and maintenance intervals, you should observe these instead of

the required intervals listed in the table. Carry out the preparatory work each time before inspection/maintenance work is car-

ried out, and carry out the completion work each time after the inspection/maintenance work is carried out.

#

Maintenance work

Interval

1

Checking leak-tightness

Each time maintenance work is

carried out

25

2

Check the general condition of the product

Annually

3

Remove any dirt from the product and vacuum chamber

Annually

4

Inspect the heat cell (condition, corrosion, soot, damage) and, if required,

carry out maintenance work.

Annually

5

Checking the gas flow pressure

Annually

23

6

Checking the CO

₂

content and, if necessary, adjusting it (air ratio setting)

Annually

24

7

Check that the connections/electrical plug connections have been con-

nected correctly/function correctly

Annually

8

Check that the gas stopcock and service valves function correctly

Annually

9

Checking and treating the heating water/filling and supplementary water

Annually

19

10

Cleaning the condensate siphon

Annually

36