III. ROUTINE INSPECTION

Consistent lubrication, rust prevention and battery charging procedures will

eliminate many possible sources of operating problems. It is also very important

for each operator to be aware of the general condition of his Ultra Lift. Each

machine should be inspected on a daily basis as detailed below:

1. Structural Condition

•

Inspect welds for any cracks that may be developing.

•

Inspect components for any bending or bulging.

a. Main Frame including Main Handles

b. Lift Frame

c. Extension Handle

d. Leverage Bar

e. Tripod. Assemble Tripod and Leverage Bar into 4 Wheel Dolly

position to confirm that they fit properly.

•

Confirm that the main wheels and axle are straight.

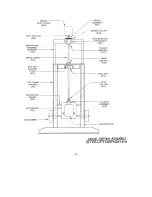

2. Hardware

•

Check to see that all screws, nuts, and bolts are tight in place. Tighten any

that are loose and immediately replace any that are missing.

•

Check speed pins and confirm that all are in place:

a. Two

¼

” speed pins in the Extension Handle

b. One

¼

” speed pin connecting the Leverage Bar to the Tripod Dolly

Legs

c. Two

½

” speed pins in the Leverage Bar

-23-

Содержание 1500

Страница 28: ... ii ...