MAINTENANCE & INSPECTION PROCEDURES

Models 1500, 1000, 1200 & 1000EV Powered Hand Trucks

I. OBJECTIVES

The Maintenance & Inspection Procedures detailed below will keep your Ultra Lift

Powered Hand Truck in safe and proper operating condition. The procedures will

minimize machine down time due to normal wear on specific components and will

help identify any operating problems as they develop. Early problem identification

will enable personnel to quickly make small corrections and avoid costly repairs.

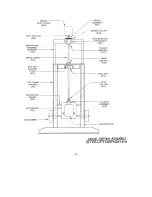

Review Section VIII of your Operator’s Manual and refer to Drawing 600.

II. REGULAR MAINTENANCE

1. Lubrication

a. Drive Screw and Ball Nut. The ball nut contains sixty-seven 1/8” diameter

bearing balls which rotate in the drive screw groove to convert rotary

motion of the drive screw into up and down movement of the frames. To

minimize drive screw and bearing wear and to reduce drag on the machine,

it is very important to keep the drive screw properly lubricated. In heavy

usage situations it is recommended that the drive screw be lubricated at

least twice each week. Lubricate the screw more often if the machine is

being used heavily on stair climbs or in a dusty or dirty environment.

•

The spray can form of Tri-Flow

TM

Superior Lubrication with Teflon is

recommended. Tri-Flow is a blend of oil and Teflon with a low

evaporation rate. It will both clean and lubricate the drive screw. A

similar product from another manufacturer (such as Super Lube or

Break Free) may be substituted if Tri-Flow is not locally available.

NEVER use grease on the drive screw. It picks

up and holds dirt and grit and will eventually

build up inside the ball nut.

NEVER use WD-40 as a lubricant. It is an

effective cleaner, but has no lubricating value.

-21-

Содержание 1500

Страница 28: ... ii ...