56 Maintenance

Dimension BST 1200es / SST 1200 es User Guide

3. Remove the XY tip calibration part from the Dimension printer.

4. Inspect the part and calibrate the X and Y axes (See

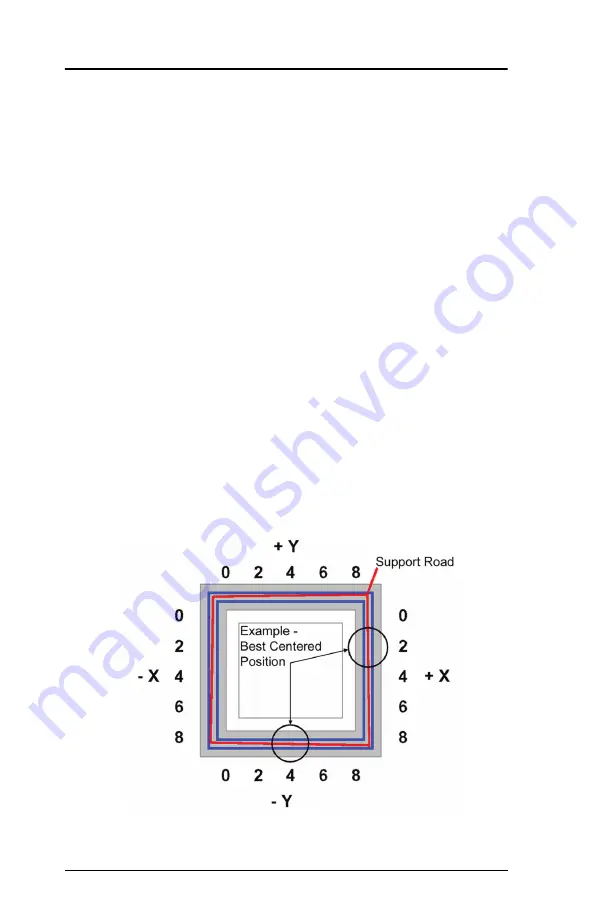

A. Use the magnifier from the Startup Kit to view the support

road (shown in red).

B. Identify the location on the +X

or

–X side of the part where

the support road is best centered within the model

boundaries (shown in blue).

C. Read the number closest to this location. This is the

required X Tip Offset adjustment, in mils. If the number is

on the -X side, a negative offset is required.

D. Select

Increment

or

Decrement

to input the X offset

adjustment - the value will change in the upper display

window (by default, the printer will be ready to accept the X

value).

E. When you are satisfied with your X offset value,

Select Y

and repeat the procedure to identify and input the required

Y Tip Offset adjustment.

5. Select

Done

after you have input the X and Y offsets. The

printer will return to

Maintenance

.

Figure 23: Example XY Tip Offset Part.

This example requires an adjustment of X = + 2 mils, Y = - 4 mils

Содержание BST 1200es

Страница 1: ...BST 1200es SST 1200es User Guide...

Страница 6: ...6 DimensionBST1200es SST1200esUserGuide...

Страница 10: ...10 DimensionBST1200es SST1200esUserGuide...

Страница 72: ...72 Troubleshooting DimensionBST1200es SST1200esUserGuide...

Страница 73: ...Dimension BST 1200es SST 1200es User Guide Troubleshooting 73...