– 48 –

7. Heat sink temperature detection control

1) IPM overheating prevention is protective control performed by a thermistor (TH sensor) in proximity to

IPM.

2) When a temperature of TH e” 83°C is detected, the fan tap is moved by 1 step up.

Thereafter step-up is performed at a rate of +1 tap/5 seconds until a maximum fan tap is reached.

3) After 2) above, operation is returned to normal fan control at a temperature of TH < 78°C.

4) Operation of the compressor is terminated at a temperature of TH e” 100°C.

5) Operation is restarted after 2 minutes and 30 seconds using [1] as the trouble count. However a count of

[4] in the same operation confirms a trouble.

The check code display is “P07” (Restart will not be performed).

∗

When trouble is confirmed, this may be a trouble caused by heat build-up or blower fan failure in the outdoor

unit, or a trouble in the IPDU board.

The correction is based on the table below:

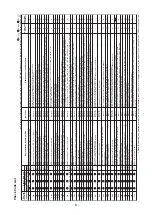

Temp. range

50˚C

≤

TO

47˚C

≤

TO < 50˚C

44˚C

≤

TO < 47˚C

39˚C

≤

TO < 44˚C

TO < 39˚C

GM224

9.0A

11.0A

14.0A

15.7A

15.7A

GM280

9.0A

11.0A

14.0A

17.6A

18.6A

TO trouble

9.0A

9.0A

Abnormal stop

Frequency normal down

Frequency slow down

Frequency hold

Frequency slow up (Up to command)

As command is

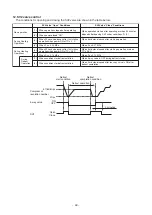

HEAT TC / COOL TL

[˚C]

e

d

c

b

a

a

b

c

d

e

HEAT

COOL

TC

TL

62˚C

57˚C

55˚C

53˚C

49˚C

63˚C

62˚C

57˚C

55˚C

51˚C

8. Electrical current release value shift control

1) This control is for the purpose of preventing malfunction

of the compressor or electronic components such as

the IPM of the inverter in the compressor drive system

during cooling operations.

2) Select the current release control value (I1) by TO

sensor value from the right table.

9. Over-current protective control

1) Operation of the compressor is stopped when the over-current protective circuit detects a trouble current.

2) The compressor restarts after 2 minutes 30 seconds using [1] as a trouble count.

After restart, the trouble count is cleared when operation continues for 6 minutes or more.

3) A trouble is confirmed when the trouble count takes a value of [8], and operation does not restart.

4) For the indicated contents of trouble, confirm on the check code list.

10. High-pressure switch/Compressor case thermostat control

1) When the high-pressure switch or the compressor case thermostat operates, the operation of the

compressor is terminated.

2) The compressor restarts after 2 minutes 30 seconds using [1] as a trouble count.

After restart, the trouble count is cleared when operation continues for 10 minutes or more.

3) A trouble is confirmed with the trouble count [10].

4) For the indicated contents of trouble, confirm on the check code list.

11. High-pressure release control

1) The operation frequency is controlled to restrain abnormal rising of high pressure by TL sensor in cooling

operation and TC sensor in heating operation.

2) When TL sensor in cooling operation or TC sensor in heating operation detects an abnormal temperature

above the stop zone, the compressor stops and the trouble count b1.

3) When the compressor is stopped with 2), the operation restarts from the point of the normal operation

zone (e point or lower) where it returned after 2 minutes 30 seconds.

4) The trouble count when the compressor stopped with 2) is cleared after the operation continued for 10

minutes. If the trouble count becomes [10] without being cleared, the trouble is determined and

reactivation is not performed.

5) For the check code display contents, confirm on the check code list.