– 107 –

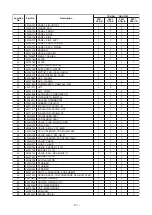

No. Part name

Procedure

Remarks

i

Compressor

and

compressor

lead

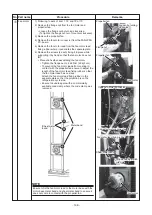

1. Removing a broken compressor

1) Recover refrigerant gas.

2) Following to work of item 1 and

f

of

c

.

3) Remove the piping panel (front).

Remove the screws from piping panel (front) and base

plate. (2 pcs, Ø4 × 10 hexagon screws)

Remove the screws from the piping panel (front) and

piping panel (rear). (1 pcs, Ø4 × 10 hexagon screw)

4) Remove the piping panel (rear). Remove the screws on

the piping panel (rear) and the bottom plate.

(2 pcs, Ø4×10 hexagon screws)

5) Remove the soundproofing material (upper, inner, and

outer).

6) Remove the compressor’s terminal cover and

compressor lead and compressor case thermostat.

7) Remove the TD sensor fixed to the discharge pipe.

8) Following to work of item 2) of 1 of

g

.

9) Remove the fixing the screws compressor lead from

the comp substrate. (3 screws)

10) Remove the fixing the screws ferrite core and

compressor lead. (1 pcs, ST3T Ø4 × 8)

11) Remove the discharge and suction pipes connected

to the compressor using a burner.

WARNING

Ensure extreme caution when removing piping by melting

the weld with a burner as fire may result if there is any oil

within the piping.

NOTE

Carefully avoid contact with the 4-way valve and PMV with

the flame (could result in a malfunction).

12) Remove the refrigeration cycle discharge and suction

pipes by pulling them upwards.

13) Remove the compressor nuts securing the

compressor to the base plate. (3 nuts)

14) Pull the compressor forwards.

NOTE

The compressor weighs at least 20kg. Ensure two people

carry out the work.

Pipe panel (front)

Pipe panel (rear)

TD sensor

Code clamp

(heat resistant)

Pipe cover

Pipe cover

Pipe cover

Compressor lead

Case thermostat

lead

Fixing the screw compressor lead

(3 screws)

Ferrite core

Fixing the screw ferrite core

(1 screw)

Compressor nuts

Remove the screws