49

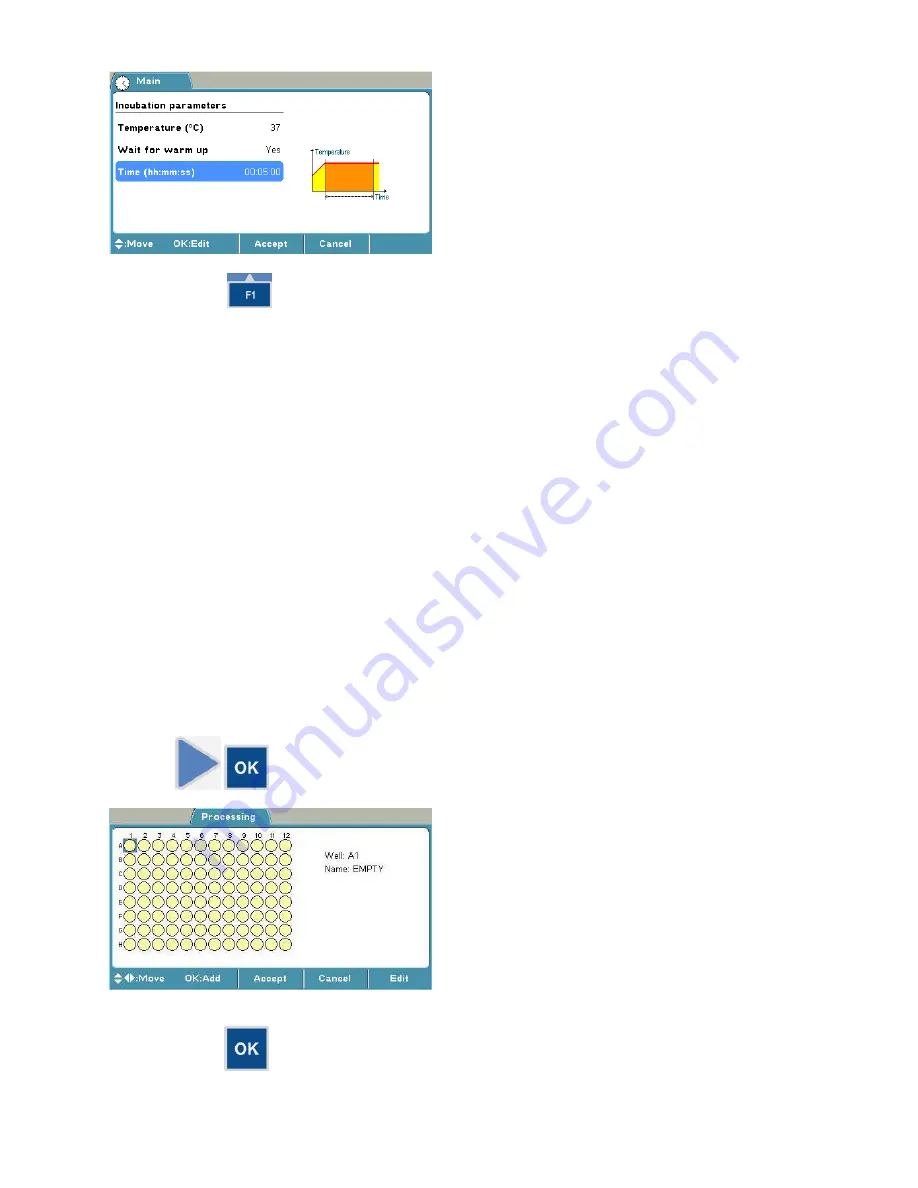

6. Press the

F1

key to accept the incubation parameters.

Programming a plate layout

You can start filling the plate layout on any of the wells of the plate. You start the fill procedure from

the well marked with a

blue

square. You can start filling a series of samples by pressing the

OK

button in the highlighted well. You can edit and delete a single well with the

Edit

function.

The plate layout parameters have to be set prior to measurement. The parameters cannot be

changed after measurement.

In this example,

a blank sample,

Calibrator 1 (Conc. 1),

Calibrator 2 (Conc. 2),

Calibrator 3 (Conc. 3),

a control sample, and

91 unknown samples

are programmed.

To create the plate layout of this example protocol:

1. Select the

Plate layout

row in the

Processing

menu using the

Right

arrow key. Then press the

OK

button to open the

Layout

window.

2. Press the

OK

button to start filling the plate from well A1.