Temperature Control Units : Veteran with LXG Series Instrument

Page: 62

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

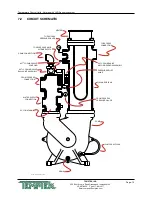

5.5 SENSOR PROBE SERVICE

A.

The temperature probe is a temperature transducer. The transducer is embedded into

a bulb well, which is threaded into the tank. The transducer converts the temperature of

the water into a proportional current output, which the microprocessor controller reads,

displays, and bases it controlling functions. The gain is automatically calibrated within the

controller electronics, the zero adjustment potentiometer is located on the CPU.

B.

Sensor probe errors are indicated by the Probe Fault screen.

When a sensor probe error is displayed, take the following steps

to correct:

1.

RECONNECTION.

If the service connection of the

sensor probe becomes saturated with water. Simply

unplug the connection, shake out the water to clear the

service connection and replug. If this was the problem, the error display should

change to Solid Red which can be cleared by pressing the Start push button. If

not, continue with replacement

.

2.

REPLACEMENT

. Replacement of the sensor probe involves ceasing process

operations (as outlined in section 3.4 of this manual) and removing the defective

sensor probe. All factory supplied replacement probes are complete with the

service connection. Unit with ‘G’ Series instruments use one sensor probe. The

“high temperature limit” safety switch is a part of the sensor probe. To replace the

sensor probe, follow the procedure as outlined below:

a.

Stop process operations as described in

section 3.4

of this manual.

b.

Determine that all process pressure is relieved and the unit’s pressure

gauges read “0” pressure.

c.

Drain the unit by removing the pump casing drain plug. The unit can be

drained only to below the sensor probe mount if preferred.

d.

Disconnect the sensor probe service plug.

e.

Using a crescent wrench, remove the sensor probe from the cylinder. To

install a new sensor probe continue as follows:

f.

The new sensor probe threads should be lined with teflon tape and

coated with leak preventative sealant. Using a crescent wrench, thread

the new sensor into the machined boss of the cylinder.

g.

Reconnect the service connection. Restart the unit as outlined in

section

3

of this manual.

Sensor Probe Fault Screen.

Содержание Veteran VT LXG Series

Страница 2: ......

Страница 6: ...Page 6 THIS PAGE INTENTIONALLY BLANK ...

Страница 20: ...Page 20 THIS PAGE INTENTIONALLY BLANK ...

Страница 42: ...Page 42 THIS PAGE INTENTIONALLY BLANK ...

Страница 48: ...Page 48 THIS PAGE INTENTIONALLY BLANK ...

Страница 68: ...Page 68 THIS PAGE INTENTIONALLY BLANK ...

Страница 95: ...END 2021 TEMPTEK INC RE 20210323 ...

Страница 96: ......