52

| Optidrive P2 User Guide |

Version 3.07

www.invertekdrives.com

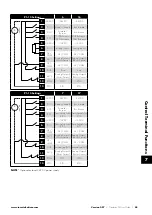

8.2. Parameter Group 3 – PID Control

8.2.1. Overview

Optidrive P2 provides an internal PID controller. Parameters for configuration of the PID controller are located together in Group 3.

For simple applications, the user needs to only define the setpoint source (P3-05 to select the source or P3-06 for a fixed setpoint),

feedback source (P3-10) and adjust the P Gain (P3-01), I time (P3-02) and optionally the differential time (P3-03).

The PID operation is uni-directional, and all signals are treated as 0 – 100% to provide a simple, intuitive operating format.

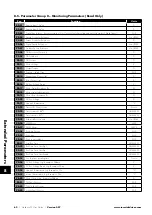

8.2.2. Parameter List

Par

Parameter Name

Minimum

Maximum

Default

Units

P3-01

PID Proportional Gain

0.0

30.0

1.0

-

PID Controller Proportional Gain. Higher values provide a greater change in the drive output frequency in response to small changes

in the feedback signal. Too high a value can cause instability.

P3-02

PID Integral Time Constant

0.0

30.0

1.0

s

PID Controller Integral Time. Larger values provide a more damped response for systems where the overall process responds slowly.

P3-03

PID Differential Time Constant

0.00

1.00

0.00

s

PID Differential Time Constant.

P3-04

PID Operating Mode

0

1

0

-

0

Direct

Use this mode if an increase in the motor speed should result in an increase in the

feedback signal.

1

Inverse

Use this mode if an increase in the motor speed should result in a decrease in the

feedback signal.

P3-05

PID Reference Select

0

2

0

-

0

Digital preset

P3-06 is used.

1

Analog Input 1

Analog Input 1 as displayed in P0-01 is used.

2

Analog Input 2

Analog Input 2 as displayed in P0-02 is used.

P3-06

PID Digital Reference Value

0.0

100.0

0.0

%

When P3-05 = 0, this parameter sets the preset digital reference (setpoint) used for the PID Controller. Where the feedback is provided

from a transducer such as a pressure transducer or level measurement, this represents the percentage of the pressure range (e.g. for a 0 –

10 Bar transducer, 4 bar = 40%) or the level.

P3-07

PID Output Upper Limit

P3-08

100.0

100.0

%

Limits the maximum value output from the PID controller.

P3-08

PID Output Lower Limit

0.0

P3-07

0.0

%

Limits the minimum output from the PID controller.

P3-09

PID Output Limit Select

0

3

0

-

0

Digital Output Limits

The output range of the PID controller is limited by the values of P3-07 & P3-08.

1

Upper limit set by analog

input 1

The output range of the PID controller is limited by the values of P3-08 & the signal

applied to Analog Input 1.

2

Lower limit set by analog

input 1

The output range of the PID controller is limited by the signal applied to Analog Input 1 &

the value of P3-07.

3

PID output added to analog

input 1

The output value from the PID Controller is added to the speed reference applied to the

Analog Input 1.

P3-10

PID Feedback Select

0

5

0

-

0

Analog Input 2

1

Analog Input 1

2

Motor Current

3

DC Bus Voltage

4

Differential : Analog Input 1 – Analog Input 2

5

Largest Value : Analog Input 1 or Analog Input 2

P3-11

PID Error To Enable Ramp

0.0

25.0

0.0

%

Defines a threshold PID error level, whereby if the difference between the setpoint and feedback values is less than the set threshold,

the internal ramp times of the drive are disabled. Where a greater PID error exists, the ramp times are enabled to limit the rate of

change of motor speed on large PID errors, and react quickly to small errors.

Setting to 0.0 means that the drive ramps are always enabled. This parameter is intended to allow the user to disable the drive internal

ramps where a fast reaction to the PID control is required, however by only disabling the ramps when a small PID error exists, the risk of

possible over current or over voltage trips being generated are reduced.

8

Extended P

arameters