10

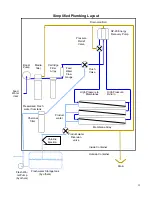

Introduction to the system

Cartridge Pre-Filters

Each system uses two 4x20” 5 micron filters as the final

stage of filtration before going to the Pearson Pump and

the seawater membranes.

There is a button on top of each housing to bleed air out

of the housing after changing filters. There are pressure

gauges on both the inlet and outlet to monitor pressure

drop across the filters. When the pressure drop across

the filters is 5 to 10psi (maximum) the filters should be

replaced.

Test Ports

There are product water test ports for each system so

the operator can confirm the produce quality. Note

that measuring the chlorine concentration should be

measured from the product tank as the chlorine injec-

tion point is too close to the sampling valve for ade-

quate mixing.

The black ABS

Drain Manifold

is the drain for the

brine discharge and the back-wash from media filters.

This manifold is open (vented) at the top and it should

be noted that if the drain line outside the watermaker

is too small or is not graded properly that this vent pipe

may need to be extended through the top of the con-

tainer.

Carbon Block Filters

Product water from the storage tank needs to be pres-

surized and connects to the “Flush Water” port on the

outside of the container. The flush water goes through

Carbon block filters for removing chlorine from the

flush water to protect the membranes.

Содержание LB-20000

Страница 2: ...2 Page Intentionally blank...

Страница 4: ...4 Page Intentionally blank...

Страница 48: ...48 Black Parker tube fittings...

Страница 49: ...49 John Guest Super Speedfit Fittings...

Страница 64: ...64...

Страница 65: ...65...