English

English

1. OVERVIEW

1. OVERVIEW

G85139-H1751-U529-D1

G85139-H1751-U529-D1

© Siemens plc 1999

© Siemens plc 1999

4/8/99

4/8/99

88

1.2

1.2 Wiring Guidelines

Wiring Guidelines to Minimise

to Minimise the Effects of

the Effects of EMI

EMI

The inverters are designed to operate in an industrial environment where a high level of Electro-Magnetic

The inverters are designed to operate in an industrial environment where a high level of Electro-Magnetic

Interference (EMI) can be expected. Usually, good installation practices will ensure safe and trouble-free

Interference (EMI) can be expected. Usually, good installation practices will ensure safe and trouble-free

operation. If problems are encountered, the following guidelines may prove useful. In particular, grounding of

operation. If problems are encountered, the following guidelines may prove useful. In particular, grounding of

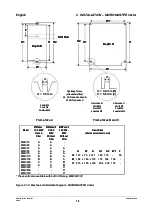

the system at the inverter, as described below, may prove effective. Figures 1.2.1-1.2.3 illustrate how an RFI

the system at the inverter, as described below, may prove effective. Figures 1.2.1-1.2.3 illustrate how an RFI

suppression filter should be installed and connected to the MICROMASTER Vector.

suppression filter should be installed and connected to the MICROMASTER Vector.

(1)

(1)

Ens

Ensure t

ure that

hat all e

all equi

quipme

pment in

nt in the c

the cubi

ubicle i

cle is wel

s well ear

l earthe

thed usi

d using sh

ng short

ort, thi

, thick ea

ck earth

rthing c

ing cabl

able con

e connec

nected t

ted to a

o a

common star point or busbar. It is particularly important that any control equipment that is connected

common star point or busbar. It is particularly important that any control equipment that is connected

to the inverter (such as a PLC) is connected to the same earth or star point as the inverter via a short,

to the inverter (such as a PLC) is connected to the same earth or star point as the inverter via a short,

thick link. Flat conductors (e.g. braids or metal brackets) are preferred as they have lower impedance

thick link. Flat conductors (e.g. braids or metal brackets) are preferred as they have lower impedance

at high frequencies.

at high frequencies.

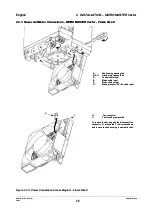

The return earth from motors controlled by the inverter should be connected directly to the earth

The return earth from motors controlled by the inverter should be connected directly to the earth

connection (PE) on the associated inverter.

connection (PE) on the associated inverter.

(2)

(2)

On

On the

the MID

MIDIMAS

IMASTER

TER Vec

Vector

tor, us

, use sa

e saw-t

w-toot

ooth wa

h washe

shers w

rs when

hen mou

mounti

nting t

ng the i

he inve

nverte

rter an

r and en

d ensur

sure th

e that a

at a

good electrical connection is made between the heatsink and the panel, removing paint if necessary.

good electrical connection is made between the heatsink and the panel, removing paint if necessary.

(3)

(3)

Whe

Wherev

rever po

er possi

ssible

ble, use

, use scr

screen

eened l

ed lead

eads for

s for con

connec

nectio

tions t

ns to the

o the con

contro

trol ci

l circu

rcuitr

itry. Te

y. Termi

rminat

nate the

e the end

ends of

s of

the cable neatly, ensuring that unscreened wires are as short as possible. Use cable glands whenever

the cable neatly, ensuring that unscreened wires are as short as possible. Use cable glands whenever

possible.

possible.

(4)

(4)

Sep

Separa

arate t

te the c

he cont

ontrol

rol cab

cables

les fro

from th

m the po

e power

wer con

connec

nectio

tions a

ns as mu

s much a

ch as po

s possi

ssible

ble, us

, using

ing sep

separat

arate tr

e trunk

unking

ing,,

etc. If control and power cables cross, arrange the cables so that they cross at 90° if possible.

etc. If control and power cables cross, arrange the cables so that they cross at 90° if possible.

(5)

(5)

Ens

Ensure

ure tha

that co

t conta

ntacto

ctors i

rs in th

n the cu

e cubic

bicle a

le are s

re supp

uppres

ressed

sed, ei

, eithe

ther wi

r with R

th R-C s

-C supp

uppres

ressor

sors fo

s for AC

r AC con

contac

tactors

tors

or ‘flywheel’ diodes for DC contactors,

or ‘flywheel’ diodes for DC contactors,

fitted to the coils

fitted to the coils

. Varistor suppressors are also effective. This

. Varistor suppressors are also effective. This

is particularly important if the contactors are controlled from the relay on the inverter.

is particularly important if the contactors are controlled from the relay on the inverter.

(6)

(6)

Use

Use scr

screen

eened o

ed or ar

r armour

moured c

ed cable

ables fo

s for th

r the mo

e motor c

tor conn

onnect

ection

ions an

s and gro

d ground

und the

the scr

screen

een at b

at both

oth end

ends vi

s via

a

the cable glands.

the cable glands.

(7)

(7)

If

If the

the drive

drive is

is to

to be

be operated

operated in

in an

an Electro-magnetic

Electro-magnetic noise-sensitive

noise-sensitive environment,

environment, the

the RFI

RFI filter

filter should

should

be used to reduce the conducted and radiated interference from the inverter. For optimum

be used to reduce the conducted and radiated interference from the inverter. For optimum

performance, there should be a good conductive bond between filter and metal mounting plate.

performance, there should be a good conductive bond between filter and metal mounting plate.

(8)

(8)

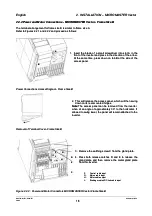

For

For Frame

Frame Size

Size A

A units

units (Fig.1.2.1),

(Fig.1.2.1), the

the flat

flat earth

earth braid

braid strap,

strap, supplied

supplied with

with the

the unit,

unit, should

should be

be fitted

fitted to

to

minimise emissions.

minimise emissions.