3

3.

. IIN

NS

ST

TA

AL

LL

LA

AT

TIIO

ON

N

–

–

M

MIID

DIIM

MA

AS

ST

TE

ER

R

V

Ve

ec

ctto

orr

E

En

ng

glliis

sh

h

© Siemens plc 1999

© Siemens plc 1999

G85139-H1751-U529-D1

G85139-H1751-U529-D1

29

29

4/8/99

4/8/99

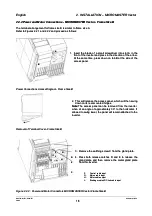

To gain access to the power and control terminals:

To gain access to the power and control terminals:

••

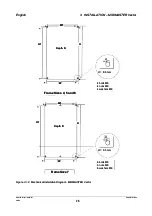

Frame size 4, 5 :

Frame size 4, 5 :

remove the four M4 screws from the front cover and remove the cover from the inverter.

remove the four M4 screws from the front cover and remove the cover from the inverter.

••

Frame size 6:

Frame size 6:

remove the six M4 screws

remove the six M4 screws from the front cover and remove the c

from the front cover and remove the cover from the inverter.

over from the inverter.

••

Frame size 7:

Frame size 7:

remove the four M4 screws from the lower front cover and remove the lower front cover from

remove the four M4 screws from the lower front cover and remove the lower front cover from

the inverter.

the inverter.

WARNING

WARNING

Ensure that the motor is configured for the correct supply voltage.

Ensure that the motor is configured for the correct supply voltage.

Make sure that the input power supply is isolated before making or changing any connections.

Make sure that the input power supply is isolated before making or changing any connections.

When synchronous machines are connected or when coupling several motors in parallel, the

When synchronous machines are connected or when coupling several motors in parallel, the

inverter must be operated with voltage/frequency control characteristic (P077= 0 or 2) and slip

inverter must be operated with voltage/frequency control characteristic (P077= 0 or 2) and slip

compensation must be disabled (P071 = 0).

compensation must be disabled (P071 = 0).

CAUTION

CAUTION

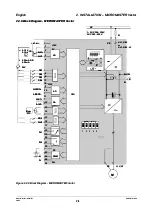

The control, power supply and motor leads

The control, power supply and motor leads

must

must

be laid separately. They must

be laid separately. They must

not

not

be fed

be fed

through the same cable conduit/trunking.

through the same cable conduit/trunking.

High voltage insulation test equipment must

High voltage insulation test equipment must

not

not

be used on cables connected to the inverter.

be used on cables connected to the inverter.

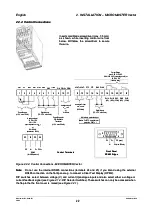

Use screened cable for the control cable, Class 1 60/75

Use screened cable for the control cable, Class 1 60/75

o

o

C copper wire only.

C copper wire only.

Feed the cables through the correct glands in the base of the inverter. Secure the cable glands to the inverter

Feed the cables through the correct glands in the base of the inverter. Secure the cable glands to the inverter

and connect the leads to the power, motor and control terminals in accordance with the information supplied in

and connect the leads to the power, motor and control terminals in accordance with the information supplied in

sections 3.2.1 and 3.2.2. Ensure that the leads are connected correctly and the equipment is properly earthed.

sections 3.2.1 and 3.2.2. Ensure that the leads are connected correctly and the equipment is properly earthed.

Frame size 4 and 5:

Frame size 4 and 5:

Tighten up each of the power and motor terminal screws to 1.1 Nm

Tighten up each of the power and motor terminal screws to 1.1 Nm

..

Frame size 6:

Frame size 6:

Tighten up each of the power and motor terminal Allen-screws to 3.0 Nm

Tighten up each of the power and motor terminal Allen-screws to 3.0 Nm

..

Frame size 7:

Frame size 7:

Tighten up each of the M12 power and motor terminal nuts to 30 Nm.

Tighten up each of the M12 power and motor terminal nuts to 30 Nm.

Secure the front cover to the inverter when all connections are complete.

Secure the front cover to the inverter when all connections are complete.

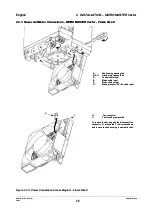

3.2.1

3.2.1 Power a

Power and Motor

nd Motor Connections

Connections

1.

1. Ensure that the pow

Ensure that the power source supplies

er source supplies the correct voltage

the correct voltage and the necessary

and the necessary current.

current. Ensure that the

Ensure that the

appropriate circuit-breaker or fuses with the specified current rating are connected between the power

appropriate circuit-breaker or fuses with the specified current rating are connected between the power

supply and inverter

supply and inverter

(see section 8)

(see section 8)

..

2.

2. Connect the pow

Connect the power input to

er input to the power termi

the power terminals L1, L2,

nals L1, L2, L3 (3 phase)

L3 (3 phase) and

and earth (PE) (

earth (PE) (

shown in Figure 3.2.1

shown in Figure 3.2.1

))

using a 4-core cable and lugs to suit the cable size. For the cross-section of each core, see section 8.

using a 4-core cable and lugs to suit the cable size. For the cross-section of each core, see section 8.

3.

3. Use a 4-core screened cable and suitable lugs to connect the motor leads to the motor terminals U, V, W

Use a 4-core screened cable and suitable lugs to connect the motor leads to the motor terminals U, V, W

and earth (PE) (

and earth (PE) (

shown in Figure 3.2.1

shown in Figure 3.2.1

).

).

Note:

Note:

For operation with cables longer than 25m see section 1.3.4

For operation with cables longer than 25m see section 1.3.4

4.

4. If required, connect the braking

If required, connect the braking unit leads to the DC

unit leads to the DC- and DC+ terminals.

- and DC+ terminals.

5.

5. Tighten all

Tighten all the power

the power and motor

and motor terminals.

terminals.

Asynchronous

Asynchronous and

and synchronous

synchronous motors

motors can

can be

be connected

connected to

to the

the MIDIMASTER

MIDIMASTER Vector

Vector inverters

inverters either

either

individually or in parallel.

individually or in parallel.

Note

Note

:

: If a synchronous

If a synchronous motor is connected

motor is connected to the inverter,

to the inverter, the motor current

the motor current may be two

may be two and a half

and a half to three

to three

times greater than that expected so the inverter must be de-rated accordingly.

times greater than that expected so the inverter must be de-rated accordingly.